Carbon nanotube composite high-performance concrete with impact resistance

A carbon nanotube composite, high-performance concrete technology, applied in the field of building materials, can solve problems such as high price and high dosage, and achieve the effects of reducing self-shrinkage, improving energy absorption, and improving compactness

Inactive Publication Date: 2019-11-05

DALIAN UNIV OF TECH

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the high price and relatively high dosage of nanoparticles (generally accounting for 1%-10% of cement quality) make them have certain disadvantages in terms of economic benefits.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0046] Table 1 Raw materials and parts by weight thereof

[0047]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

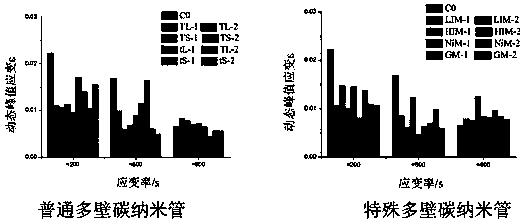

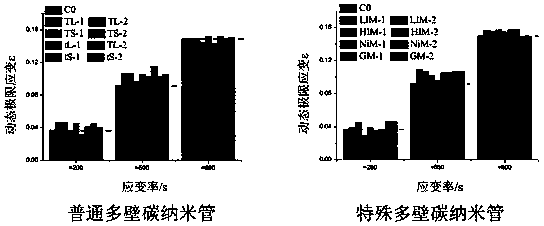

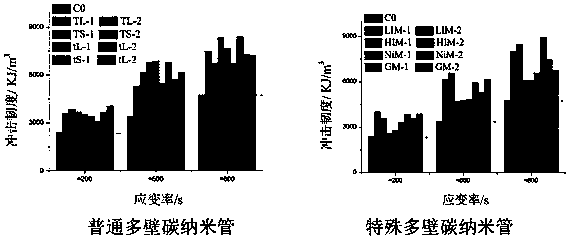

The invention discloses a carbon nanotube composite high-performance concrete with impact resistance. The carbon nanotube composite high-performance concrete with impact resistance is characterized inthat the raw materials of the carbon nanotube composite high-performance concrete with impact resistance include cement, multi-walled carbon nanotubes, silica fume, fly ash, sands, a water reducer and water; and the multi-walled carbon nanotubes are one of ordinary multi-walled carbon nanotubes, special-structure multi-walled carbon nanotubes and surface-treated multi-walled carbon nanotubes. Themulti-walled carbon nanotubes can significantly enhance the dynamic compressive strength and the impact toughness of the high-performance concrete. When the strain rate is in a range of 200-800 / s andthe dosage of the multi-walled carbon nanotubes is 0.25-0.5%, the dynamic compressive strength of concrete can be maximally increased by 99.6%, and the impact toughness can be maximally increased by100.8%.

Description

technical field [0001] The invention relates to the technical field of building materials, in particular to a carbon nanotube composite high-performance concrete with impact resistance. Background technique [0002] Due to its excellent properties such as high durability, high workability, high strength and high volume stability, high-performance concrete has shown its unique advantages in bridges, high-rise buildings, harbor buildings and military bunkers. However, as a multi-phase and multi-scale material, the high brittleness and low energy consumption of high-performance concrete make it prone to collapse once the limit of bearing capacity is exceeded. What is more serious is that under high strain rate dynamic impact load, the compression time of concrete becomes shorter, the effective stress area decreases, and the brittle failure of concrete materials will be further aggravated, seriously affecting the safety of concrete structures. [0003] In engineering, steel fib...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/04C04B14/02

CPCC04B14/026C04B28/04C04B18/08C04B18/146C04B14/06C04B22/002C04B2103/302

Inventor 韩宝国王佳亮董素芬

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com