Porous nano manganese oxide catalyst, preparation and application thereof

A technology of manganese oxide and catalyst, which is applied in the field of porous nano-manganese oxide catalyst, which can solve the problems of surface defects, multi-water resistance, low light-off temperature, high light-off temperature, etc., to achieve rich oxygen vacancies and defect sites, and low light-off temperature , The effect of low catalytic ignition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

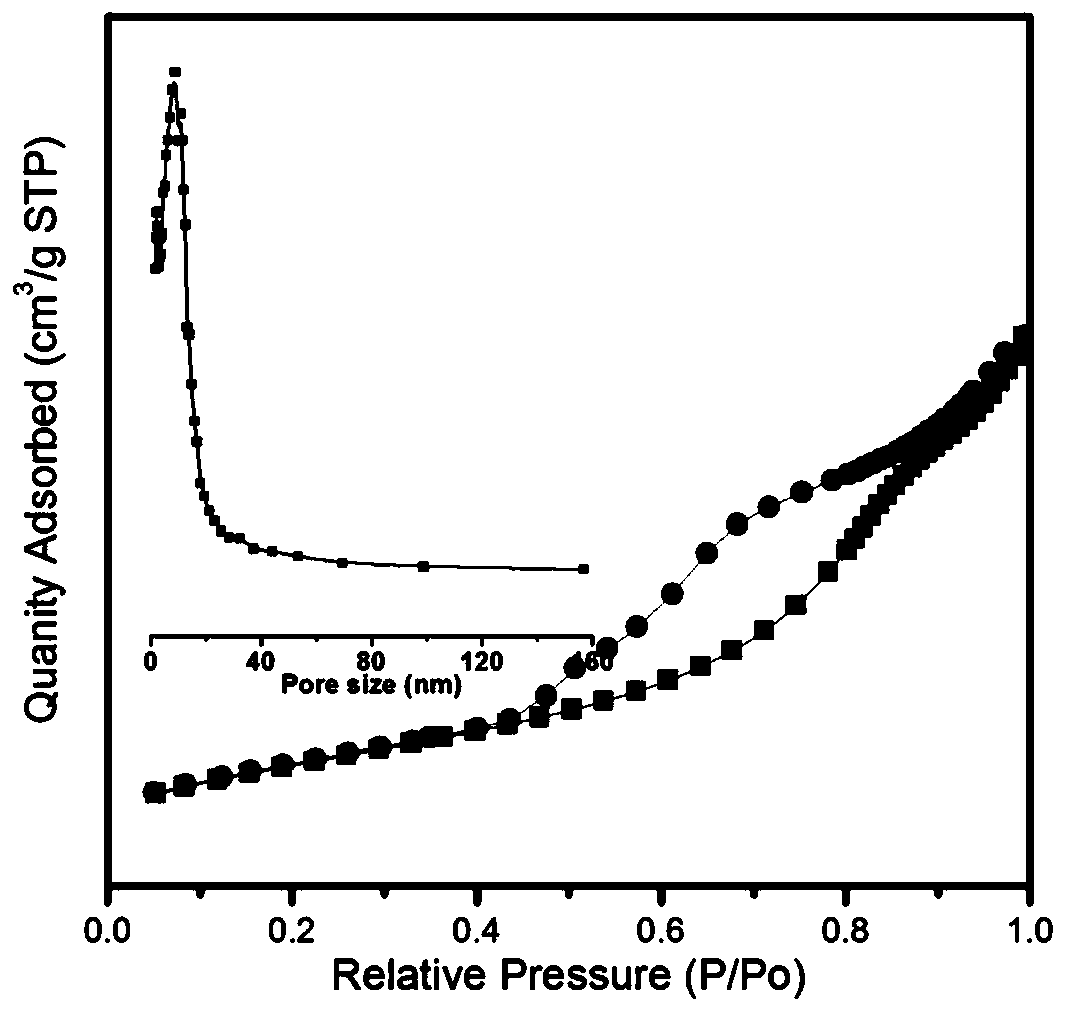

[0038] The invention also provides a porous nano manganese oxide catalyst prepared according to the preparation method. The specific surface area of the porous nano manganese oxide is 145m 2 / g-220m 2 / g; the porous nano manganese oxide is manganese trioxide.

[0039] The invention also provides the application of the porous nano-manganese oxide catalyst as a catalyst for catalytic combustion of volatile organic compounds.

[0040]The volatile organic compound in the present invention is a volatile compound with a boiling point of 50-260° C. and a saturated vapor pressure exceeding 133.322 Pa at room temperature. In some embodiments, the volatile organic compound is toluene, ethanol or chlorobenzene.

[0041] When the manganese trioxide prepared by the invention is applied to the catalytic combustion of volatile organic compounds, it has the advantages of high specific surface area, uniform pore size distribution, high catalytic activity, strong stability, excellent water ...

Embodiment 1

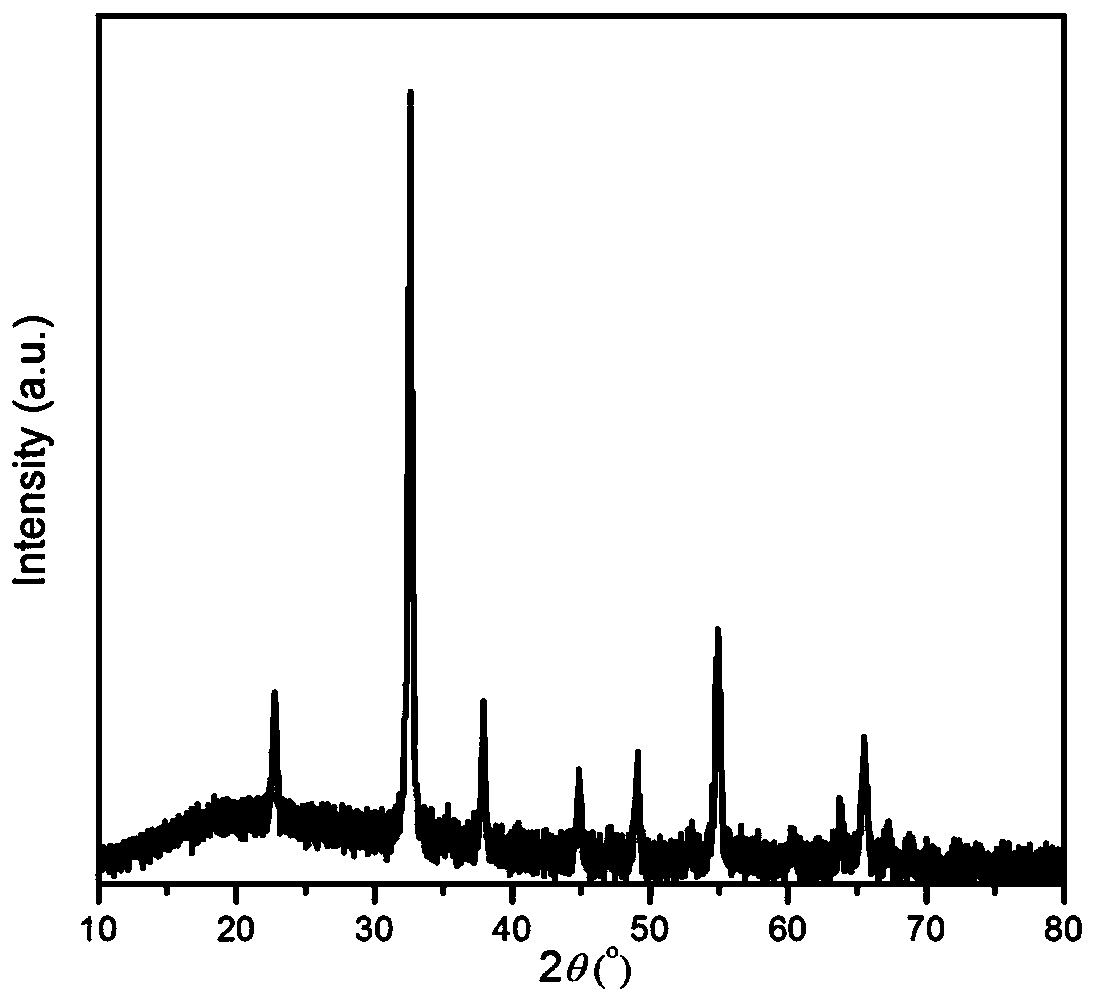

[0044] Add 7.16g of manganese nitrate solution and 1g of glycine into 10mL of water in a quartz crucible, put the above solution into a 350°C reaction for 30min after ultrasonication for 15min to obtain a powder sample; burn the obtained powder sample with deionized water and filter it, Porous nano-manganese oxide was obtained after air-drying at 110°C. The XRD figure of the porous nano-manganese oxide catalyst obtained in the present embodiment is as follows figure 1 shown by figure 1 It can be known that the porous nano-manganese oxide obtained in this example presents a diffracted crystal form of manganese trioxide by comparing with the standard PDF card.

Embodiment 2

[0046] 7.16g of manganese nitrate solution and 1g of glycine were added to 10mL of ethanol, ultrasonicated in a quartz crucible for 15min, and then the above solution was placed at 450°C for 10min to react to obtain a powder sample. Then, the resulting powder sample was washed, filtered, and air-dried at 110° C. to obtain a porous nano manganese oxide catalyst. The SEM figure of the porous nano-manganese oxide catalyst obtained in the present embodiment is as follows figure 2 shown by figure 2 It can be seen that the manganese oxide obtained in the examples exhibits a typical porous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com