Ferrite powder, resin composition, and molded body

A technology of resin composition and ferrite, which is applied in the direction of iron compounds, magnetic objects, crystal growth, etc., can solve the problems of reduced coercive force, reduced magnetic properties of magnetic powder, excellent dispersibility of difficult magnetic powder, etc., and achieves high coercive force , small particle size, excellent dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0098] As an example of the preparation method of a ferrite raw material (granulation), the following methods are mentioned. That is, first, Fe raw material and Sr raw material are weighed in appropriate amounts to make it into a desired ferrite component, and then pulverized by adding water to prepare a slurry. Then, the prepared slurry is granulated with a spray dryer, and if necessary, pulverized and classified to prepare a granulated product having a predetermined particle diameter.

[0099] Examples of the classification method include air classification, screen filtration, sedimentation, and classification using various sieves.

[0100] Although the average particle diameter of the granulated material is not particularly limited, it is preferably not less than 0.5 μm and not more than 30 μm.

[0101] The average particle diameter can be obtained, for example, by measuring the particle diameter D50 at which the cumulative particle size distribution on a volume basis is 5...

Embodiment 1

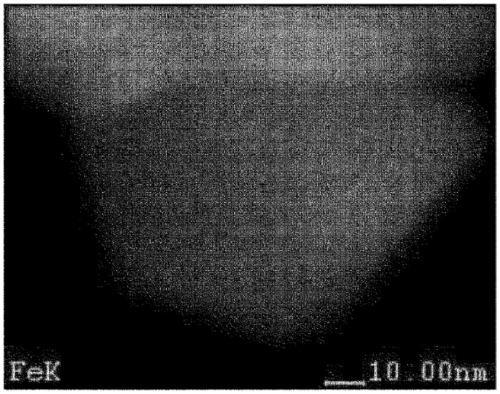

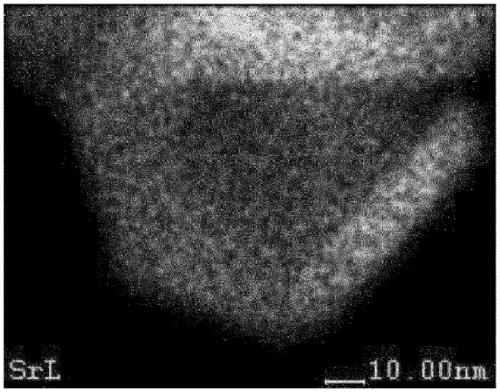

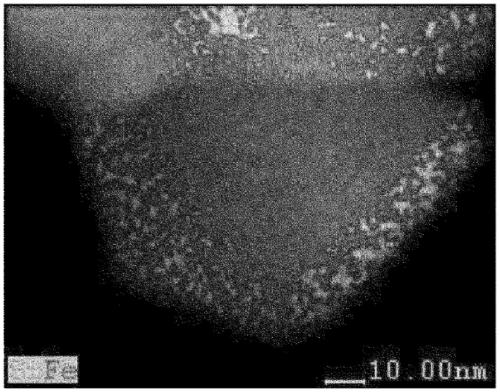

[0178] First, the molar ratio of Fe 2 o 3 / SrCO 3 = 5.75 ratio to measure iron oxide (Fe 2 o 3 ) and strontium carbonate (SrCO 3 ), and mixed, water was added thereto, and pulverized to prepare a slurry with a solid content of 50% by mass. Next, the prepared slurry was granulated with a spray dryer, and classified with a gyro shifter and a turbo classifier to prepare a granulated product with an average particle diameter of 15 μm.

[0179] Next, pass a 10Nm 3 / hour supply propane at 35Nm 3 Oxygen is supplied per hour, and the conveying speed of the granulated matter is about 40m / s, and the temperature is 2000°C, and thermal spraying is carried out to ferrite it, and then, it is carried by the air flow of the air supply to be transported, thereby rapidly cooling it in the atmosphere. At this time, since thermal spraying is performed while making the granulated material flow continuously, the particles after thermal spraying and rapid cooling are not bonded to each othe...

Embodiment 2、3

[0183] Ferrite powder was produced in the same manner as in Example 1 above, except that the mixing ratios of iron oxide and strontium carbonate were changed as described in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com