A kind of preparation method of porous carbon ball negative electrode material for lithium battery

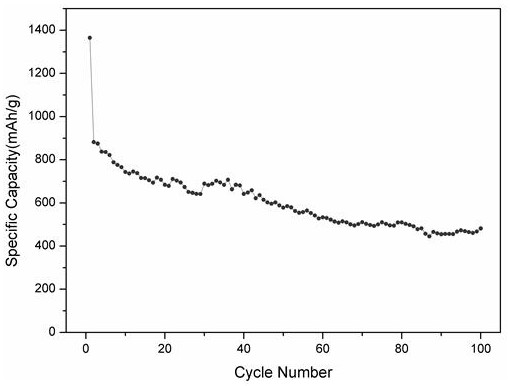

A technology of negative electrode material and porous carbon is applied in the field of preparation of porous carbon ball negative electrode material for lithium battery, which can solve the problems of poor electrochemical performance, poor electrode wettability, large irreversible capacity, etc. Low cost and the effect of alleviating film formation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

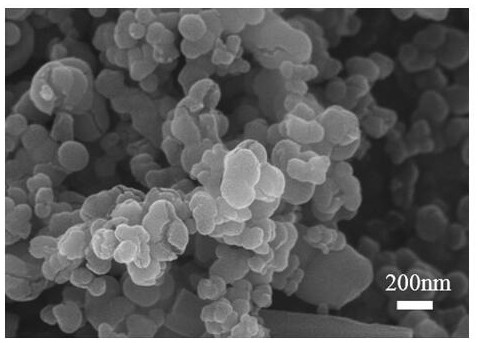

[0033] 1) Under the protection of an argon gas atmosphere with a flow rate of 200mL / min, the tube furnace was heated to 450°C at a heating rate of 5°C / min, and kept for 30 minutes, and then acetylene gas was introduced at a flow rate of 200mL / min for 1 hour to obtain nano carbon spheres;

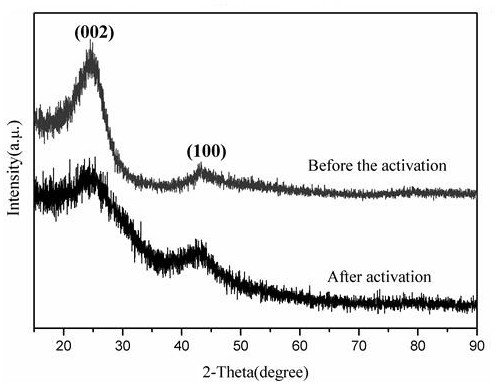

[0034] 2) Add alkaline substances (the molar ratio of sodium hydroxide and sodium carbonate is 1:3) to the nanocarbon spheres obtained in step 1), so that the mass ratio of nanocarbon spheres to alkaline substances is 1:4, and then at 200 Under the protection of mL / min argon gas flow rate, the temperature was raised to 900 °C for 30 min at a heating rate of 5 °C / min, then sintered for 4 h for activation treatment, cooled to room temperature, washed until neutral, and passed through a 300-mesh porous sieve after grinding Porous carbon spheres are obtained after sieving;

[0035] 3) Put the porous carbon spheres prepared in step 2) in a 2 mol / L nitric acid solution, and stir at 60°C for 3 hou...

Embodiment 2

[0037]1) Under the protection of argon gas at a flow rate of 100mL / min, the tube furnace was heated to 550°C at a heating rate of 5°C / min, kept for 40min, and then acetylene gas at a flow rate of 100mL / min was introduced for 2h for cracking reaction to obtain nano carbon spheres;

[0038] 2) Add alkaline substances (the molar ratio of potassium hydroxide and ammonium carbonate is 1:1) to the carbon nanospheres obtained in step 1), so that the mass ratio of carbon nanospheres to alkaline substances is 1:5, and then Under the protection of 100 mL / min inert gas flow rate, the temperature was raised to 800 °C at a heating rate of 5 °C / min for 40 min, and then sintered for 3 h for activation treatment, cooled to room temperature, washed to neutral, and passed through a 400-mesh porous sieve after grinding Porous carbon spheres are obtained after sieving;

[0039] 3) Put the porous carbon spheres prepared in step 2) in a 6mol / L nitric acid solution, and stir at a constant temperatu...

Embodiment 3

[0041] 1) Under the protection of argon gas at a flow rate of 400mL / min, the tube furnace was heated to 580°C at a heating rate of 10°C / min, kept for 30 minutes, and then acetylene gas at a flow rate of 400mL / min was introduced for 2 hours to obtain nano carbon spheres;

[0042] 2) Add sodium hydroxide to the nanocarbon spheres obtained in step 1), so that the mass ratio of nanocarbon spheres to alkaline substances is 1:8, and then under the protection of 400 mL / min inert gas flow rate, according to 10 ℃ / The heating rate was raised to 900°C for 30 minutes, then sintered for 1 hour for activation treatment, cooled to room temperature, washed until neutral, and then sieved with a 300-mesh porous sieve to obtain porous carbon spheres after grinding;

[0043] 3) Put the porous carbon spheres prepared in step 2) in a 5 mol / L nitric acid solution, and stir at 90°C for 2 hours at a constant temperature. After the reaction, filter with suction, wash until neutral, and dry to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com