Low-temperature rapid polymerization starch-based superabsorbent polymer and its preparation method

A water-absorbing polymer and polymerization-type technology, applied in fertilizer mixtures, agriculture, fertilization equipment, etc., can solve the problems of high polymerization reaction temperature, complicated preparation of raw materials, long reaction time, etc., achieve high gelatinization temperature, wide range of sources, low Effect of Iodine Affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

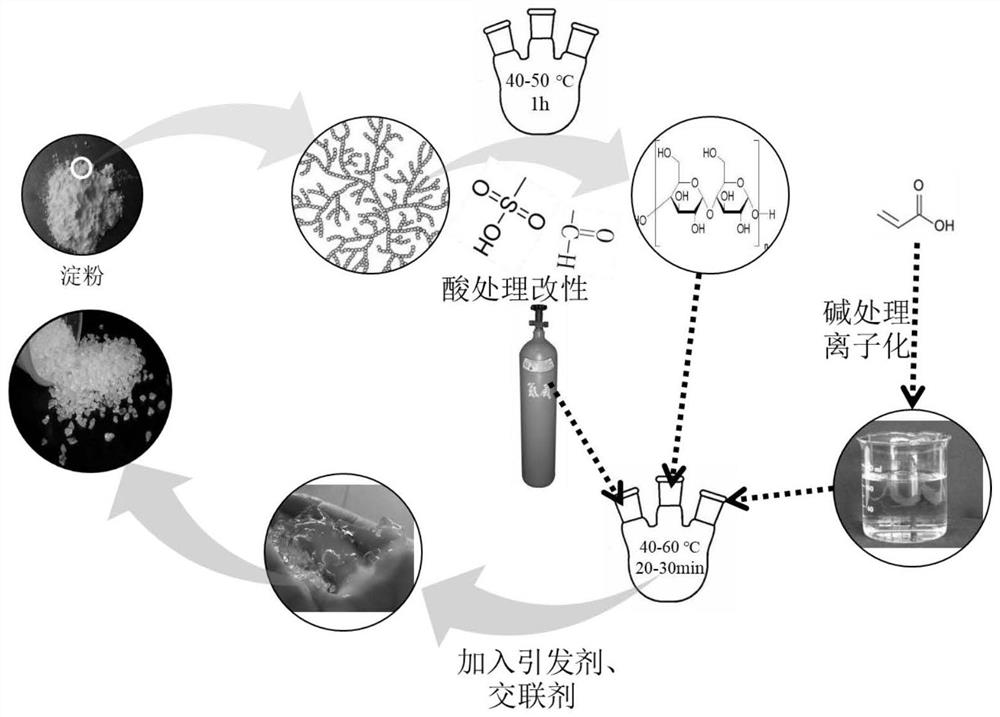

Method used

Image

Examples

Embodiment 1

[0057] (1) Get analytically pure soluble cornstarch in a three-neck flask, add water to make a starch homogenate with a weight percentage of 40%, add 1.25% of cornstarch weight sulfamic acid as an acid modifier, heat in a water bath at 50°C, and mechanically After stirring for 1 hour, the denatured starch homogenate was poured out, and dried at 50° C. to obtain acid-modified corn starch.

[0058] (2) After dissolving the acid-modified starch prepared in step (1) with 2 times the weight of water, add ammonium persulfate initiator, dissolve together and stir for 30 minutes to generate persulfate radicals, and pass into the reaction system Nitrogen is used to remove oxygen in the reaction system.

[0059] (3) Using acrylic acid as a reactive monomer, use a NaOH solution with a concentration of 3mol / L to neutralize the acrylic acid to a neutralization degree of 65% in an ice bath, and then add the crosslinking agent N, N-methylenebisacrylamide , dissolved into a homogeneous solut...

Embodiment 2

[0065] Take 300g of unrefined cornstarch, add 800g of deionized water and stir at a constant speed at 50°C for 2h, add 100ml of 3% sulfurous acid solution, continue to stir for 1h, take it out and dry it to prepare acid-modified cornstarch.

[0066] Weigh 100g of acid-modified cornstarch, 200g of water, and 500g of acrylamide, put them into the reactor, add 100ml of 5% ammonium persulfate aqueous solution, pass through nitrogen, stir at 60°C for 1h, then add N,N-methylene After 5.0 g of bisacrylamide was stirred and reacted for 30 minutes, a viscoelastic crude product was obtained. The crude product was taken out, washed with excess deionized water, dried and ground to obtain a superabsorbent polymer. The product absorbs 863.3 times in deionized water and 97.6 times in normal saline.

Embodiment 3

[0068] Weigh 800g of industrial starch, add 5000ml of tap water, heat in a water bath at 45°C in the reactor and stir at a constant speed for 1h, add 500ml of 1.5% aqueous sulfamic acid solution, continue stirring for 1h, add 750ml of 5% ammonium persulfate aqueous solution, and then pass Nitrogen: Weigh 5000g of industrial-grade acrylic acid, add 8L of 5mol / L industrial sodium hydroxide solution, and carry out neutralization treatment. After the acrylic acid solution is cooled, add it to the reaction kettle, and add 5% N,N-methylenebisacrylamide solution dropwise After 125ml, continue to stir, and after about 20-30 minutes, a viscoelastic crude product can be formed. After taking it out, wash it, dry it and grind it to obtain a superabsorbent polymer. The water absorption of this product is 986.78 times in deionized water and 124.5 times in normal saline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com