Electrode sheet, all-solid battery, manufacturing method for electrode sheet, and manufacturing method for all-solid battery

An all-solid-state battery and manufacturing method technology, applied in the field of electrode sheets, can solve the problems of reduced battery capacity, increased internal resistance of the battery, and poor contact state, and achieve the effects of interface resistance suppression, low internal resistance, and good contact state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

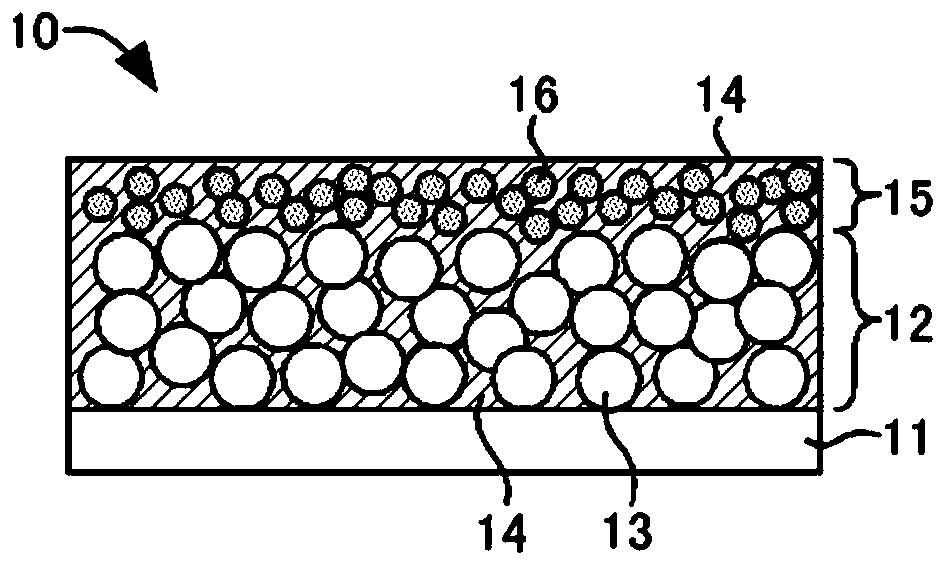

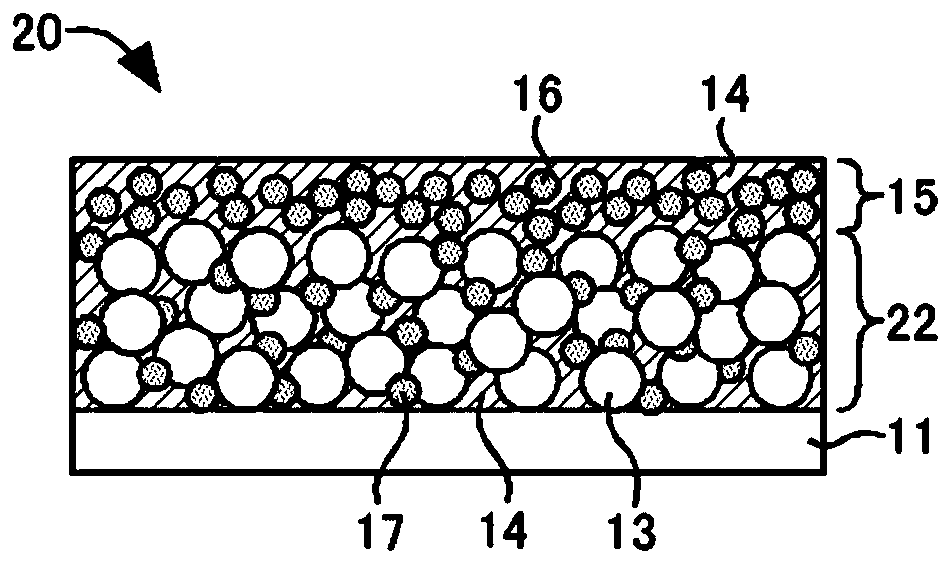

[0109] First, the inventors found that the lithium ion conductivity between the inorganic solid electrolyte particles was effectively developed by forming a polymer solid electrolyte between the inorganic solid electrolyte particles in the spacer layer by the following method. That is, after the inorganic solid electrolyte layer using polyvinylidene fluoride (PVdF) as a binder is formed on the aluminum foil, the polymer solid electrolyte solution is soaked into the inorganic solid electrolyte layer, and the aluminum foil is placed in contact thereon. Afterwards, the polymer cross-linking in the polymer solid electrolyte solution was hardened by a polymerization reaction to form an all-solid electrolyte layer in which the polymer solid electrolyte penetrated into the inorganic solid electrolyte particles and its ion conductivity was evaluated. Here, the inorganic solid electrolyte particles use Li particles with a particle size of about 1 μm. 1+x al y Ge 2-y (PO 4 ) 3 (LAGP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com