Telescopic flexible conductive film and preparation method thereof

A flexible conductive and conductive paste technology, applied to the conductive layer on the insulating carrier, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of inability to stretch, increase of circuit resistance, Environmental pollution and other issues to achieve the effect of improving aesthetics and reducing the rate of resistance change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Main equipment: screen printing machine, gravure printing machine, dispensing machine, R2R two-way compound machine.

[0032] This example provides two kinds of nano-silver pastes, which are respectively marked as No. ① nano-silver paste and No. ② nano-silver paste. The specific formula composition is shown in Table 1.

[0033] Table 1 The formula composition of two kinds of nano-silver pastes provided by this embodiment

[0034]

[0035] 1. Preparation of flexible conductive film A:

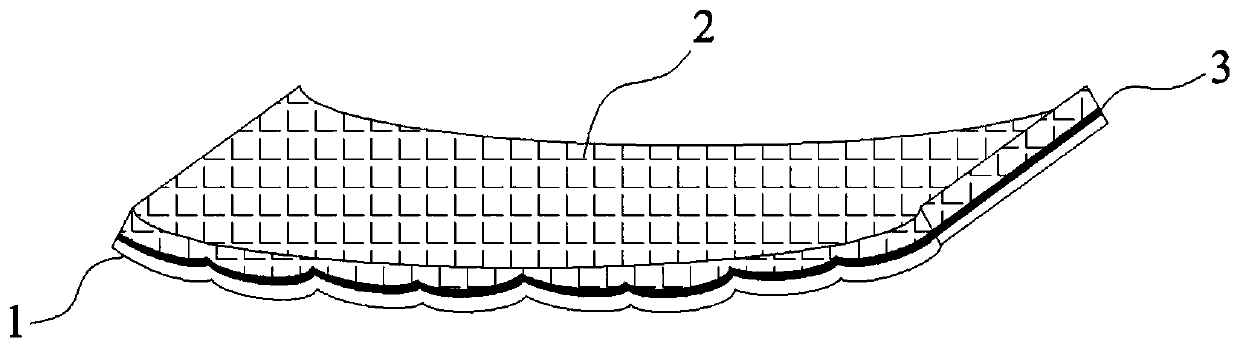

[0036]S1. Pour No. ① nano-silver paste prepared in embodiment 1 into a screen printing machine, and print conductive patterns on one of the surfaces of the TPU film (equivalent to the first elastic substrate layer 1) of 75 μm; Baking at -150° C. for 15-60 minutes; after the baking, a non-fluid conductive circuit, ie, the conductive circuit layer 3 , is formed on the surface of the TPU film.

[0037] S2. Transfer the composite structure obtained after the S1 treatment to the R2R bidir...

Embodiment 2

[0134] 1. Experiment setup method

[0135] Stretchability experiment operation: set the tensile strain to 400%, and stretch the cycle 250 times.

[0136] Bendability test operation: use 2kg pressure, 180 degrees positive and negative folding 250 times.

[0137] 2. Data collection

[0138] The SX1944 digital four-probe tester characterizes the sheet resistance of the film, and takes 5 points evenly for each FPC to be tested.

[0139] 3. Test object

[0140] Experimental group: flexible conductive film A and flexible conductive film B prepared in Example 1, flexible conductive film A1 and flexible conductive film B1 prepared in Example 2, flexible conductive film A2 and flexible conductive film B2 prepared in Example 3;

[0141] Control FPC ①. Copper-clad PI film FPC (Shenzhen Qiyuanxing Electronics Co., Ltd.); Control FPC ②. Flexible metal wire FPC; For FPC ③. Metal-coated elastic braided flexible wire FPC (Dongguan Huaxing Rope Technology Co., Ltd.); Film ④. Flexible silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com