Catalytic system coupled with ATP regeneration system and application of catalytic system in glutathione production

A catalytic system and regeneration system technology, applied in the direction of application, microbial-based methods, biochemical equipment and methods, etc., can solve the problems of unfriendly antibiotics, unfriendly antibiotic environment, low product yield, etc., to save time, cost and equipment Cost, save antibiotic use, good biosafety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1. Construction of recombinant Escherichia coli

[0033] 1. Construction of recombinant expression vectors

[0034] Codon optimization was performed on the target gene GshF (SEQ ID NO.1) derived from Streptococcus thermophilus and ppk2 (Gene ID: 3718134, VERSION: CP000143.2; SEQ ID NO.3) derived from Rhodobacter sphaeroides to obtain codon optimization The GshF gene sequence (SEQ ID NO.2) and the codon-optimized ppk2 gene sequence (SEQ ID NO.4) were used to design primers based on the codon-optimized sequence, that is, to introduce a linear The terminal sequence of the linearized vector (the terminal sequence of the linearized vector is the capital letter in the primer sequence), so that the 5' and 3' ends of the insert fragment have the consensus sequence (15-25bp) at both ends of the vector, as shown in Table 1 As shown, the primers and the template sequences were paired for high-fidelity PCR and gel-cut recovery; at the same time, the plasmid pET-30a was ...

Embodiment 2

[0051] Embodiment two, the optimization of the addition amount of glutathione synthesis reaction bacteria

[0052] In order to reduce the cost, the addition amount of BL21-GshF and BL21-ppk2 was optimized. The reaction system is as follows: L-glycine 160mM, L-sodium glutamate 160mM, L-cysteine 140mM, MgSO 4 ·7H 2O 70mM, ATP 2mM, 60mM sodium hexametaphosphate, 100mL deionized water. Wet cells were added to the reaction system, reacted at 42°C and pH 7 for 3 hours, then sampled, centrifuged at 8000rpm for 5 minutes, and the supernatant was detected by HPLC for the production of glutathione and the contents of ATP, ADP and AMP.

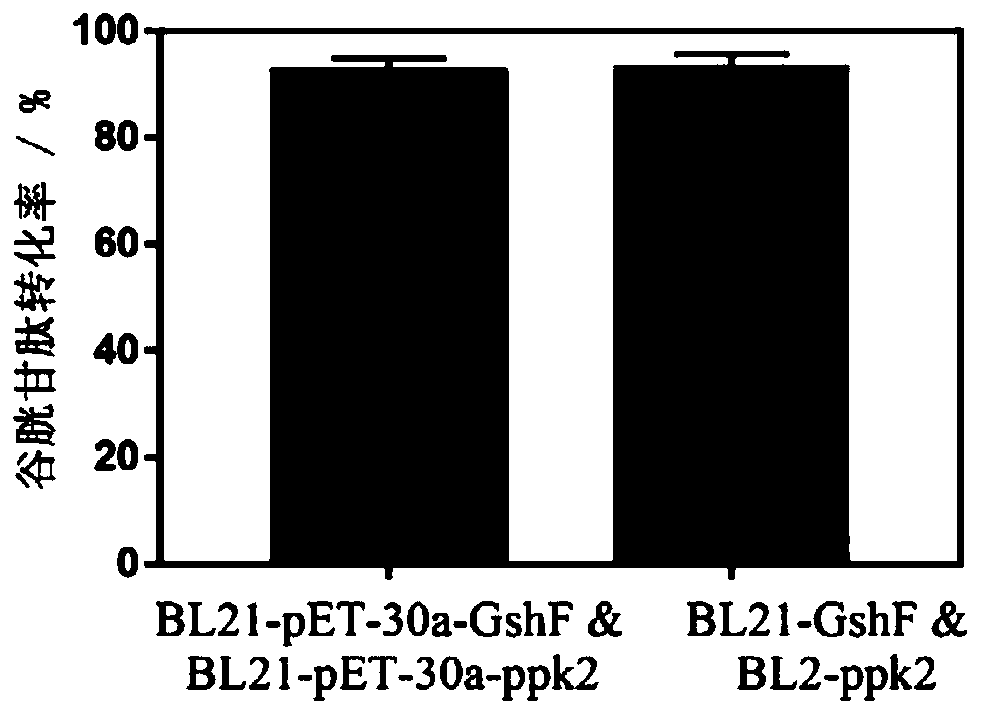

[0053] When the added amount of BL21-GshF wet cells was 50 mg, the effects of different addition amounts of BL21-ppk2 wet cells on the reaction results were compared. Such as Figure 4 As shown, 20-50 mg of BL21-ppk2 wet cells does not constitute a limiting factor for the synthesis of glutathione, and the conversion rate of glutathione in the syste...

Embodiment 4

[0056] Embodiment four, the optimization of mixed culture inoculum size

[0057] To obtain the mixed bacteria after mixing BL21-GshF and BL21-ppk2 at a ratio of 3:2, the inoculation ratio of the two must be controlled. After BL21-GshF and BL21-ppk2 were activated overnight, they were mixed according to different ratios (3:2, 2:1, 5:2, 3:1), and the mixed bacteria were inoculated with an inoculum volume of 10% by volume In the fermenter (TB medium), the temperature is maintained at 37°C±0.5°C, the pH is 6.7±0.1, by adjusting the ventilation rate (20-100L·h -1 ) and stirring speed (100-600rpm) to control the dissolved oxygen at 10%-40%, cultivate to the late logarithmic stage, put in the tank, centrifuge the bacteria, and use it as the reaction cells for later use.

[0058] Mix 50 mg of wet cells fermented with BL21-GshF and BL21-ppk2 at different inoculation ratios at 42°C and pH 7 with L-glycine 160 mM, L-sodium glutamate 160 mM, MgSO 4 ·7H 2 O 70mM, L-cysteine hydrochlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com