An extraction and separation method for reducing moisture in biomass hydrothermal liquefaction oil

A technology of hydrothermal liquefaction and separation method, which is applied in the preparation of liquid hydrocarbon mixtures, the treatment of hydrocarbon oil, and the petroleum industry. The effect of low production cost and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

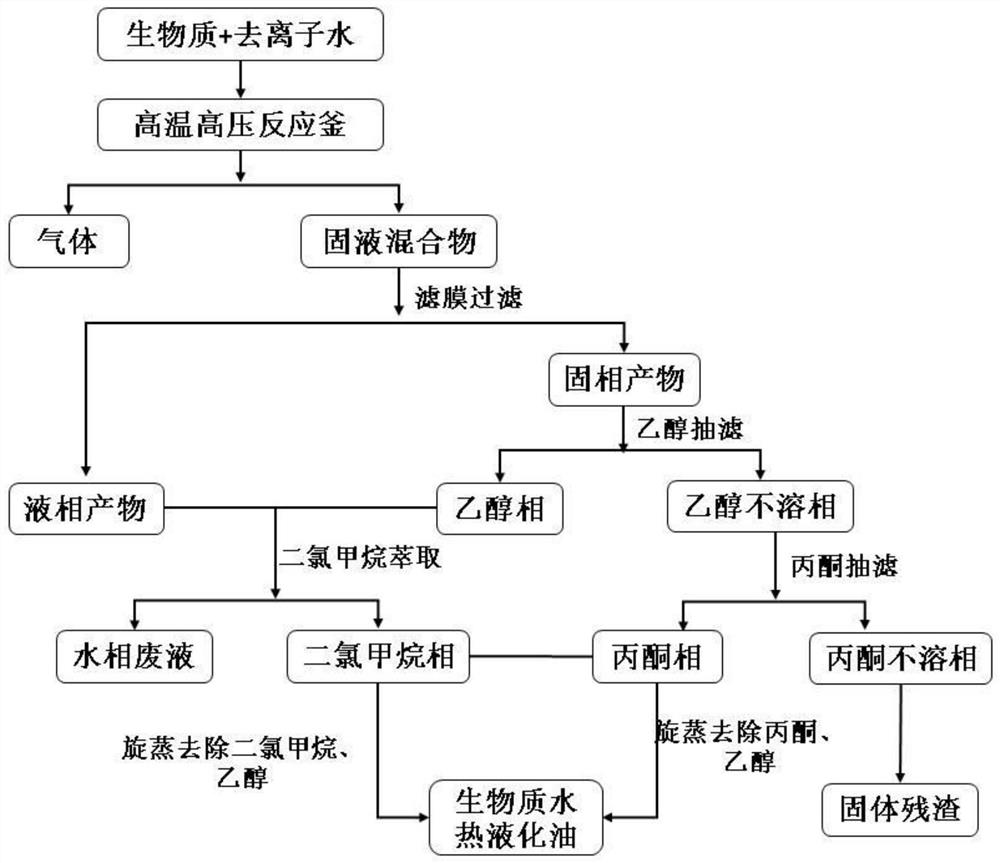

[0041] An extraction and separation method for reducing moisture in biomass hydrothermally liquefied oil, the process flow diagram is shown in figure 1 , including the following steps:

[0042] First, 15g of corn stalk powder and 150mL of deionized water were added to a batch-type high-temperature and high-pressure reactor, and after hydrothermal liquefaction at 320°C and a pressure of 10MPa, a biomass hydrothermally liquefied oil-solid-liquid mixture with a moisture content of 20.32% was obtained. A. After uniform stirring for 10 minutes, the biomass hydrothermal liquefaction oil solid-liquid mixture A is suction-filtered with a 0.45 μm organic filter membrane to obtain the biomass hydrothermal liquefaction oil-liquid phase product, which is preserved as a sample; for the solid-phase product obtained by suction filtration Add 50mL of ethanol, stir evenly for 10min, then use 0.45μm organic filter membrane to carry out suction filtration to obtain biomass hydrothermally liquefi...

Embodiment 2

[0047] An extraction and separation method for reducing moisture in biomass hydrothermally liquefied oil, the process flow diagram is shown in figure 1 , including the following steps:

[0048]First, 15g of corn stalk powder and 150mL of deionized water were added to a batch-type high-temperature and high-pressure reactor. After hydrothermal liquefaction at 320°C and a pressure of 10MPa, a biomass hydrothermally liquefied oil-solid-liquid mixture with a moisture content of 18.85% was obtained. A. After stirring evenly for 20 minutes, the biomass hydrothermal liquefaction oil solid-liquid mixture A is suction-filtered with a 0.45 μm organic filter membrane to obtain the biomass hydrothermal liquefaction oil-liquid phase product, and save the reserved sample; the solid-phase product obtained by suction filtration Add 50mL of ethanol, stir evenly for 20min, then use 0.45μm organic filter membrane to carry out suction filtration to obtain biomass hydrothermally liquefied oil treat...

Embodiment 3

[0052] An extraction and separation method for reducing moisture in biomass hydrothermally liquefied oil, the process flow diagram is shown in figure 1 , including the following steps:

[0053] First, 15g of corn stalk powder and 150mL of deionized water were added to a batch-type high-temperature and high-pressure reactor. After hydrothermal liquefaction at 320°C and a pressure of 10MPa, a biomass hydrothermally liquefied oil-solid-liquid mixture with a moisture content of 21.96% was obtained. A. After uniform stirring for 15 minutes, the biomass hydrothermal liquefaction oil solid-liquid mixture A is suction-filtered with a 0.45 μm organic filter membrane to obtain the biomass hydrothermal liquefaction oil-liquid phase product, and the reserved sample is preserved; the solid phase obtained by suction filtration Add 100mL of ethanol and methanol mixed alcohol with a volume ratio of 1:1 to the product, stir evenly for 15min, and then filter with 0.45μm organic filter membrane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com