A kind of creep type viscoelastic rubber waterproof coating and production method thereof

A waterproof coating and rubber technology, applied to asphalt coatings, coatings, conjugated diene coatings, etc., can solve the problems of cumbersome operation steps, increase labor intensity of workers, increase initial viscosity, etc., and achieve high solid content and long storage life long, creep-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

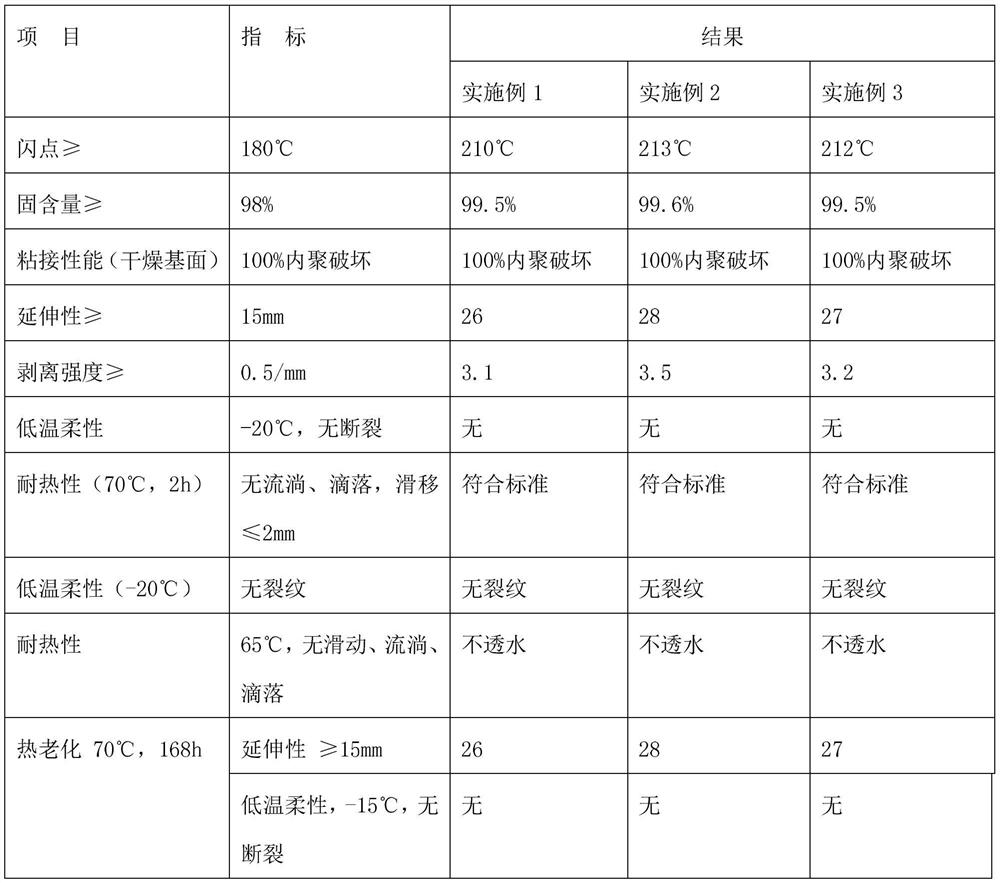

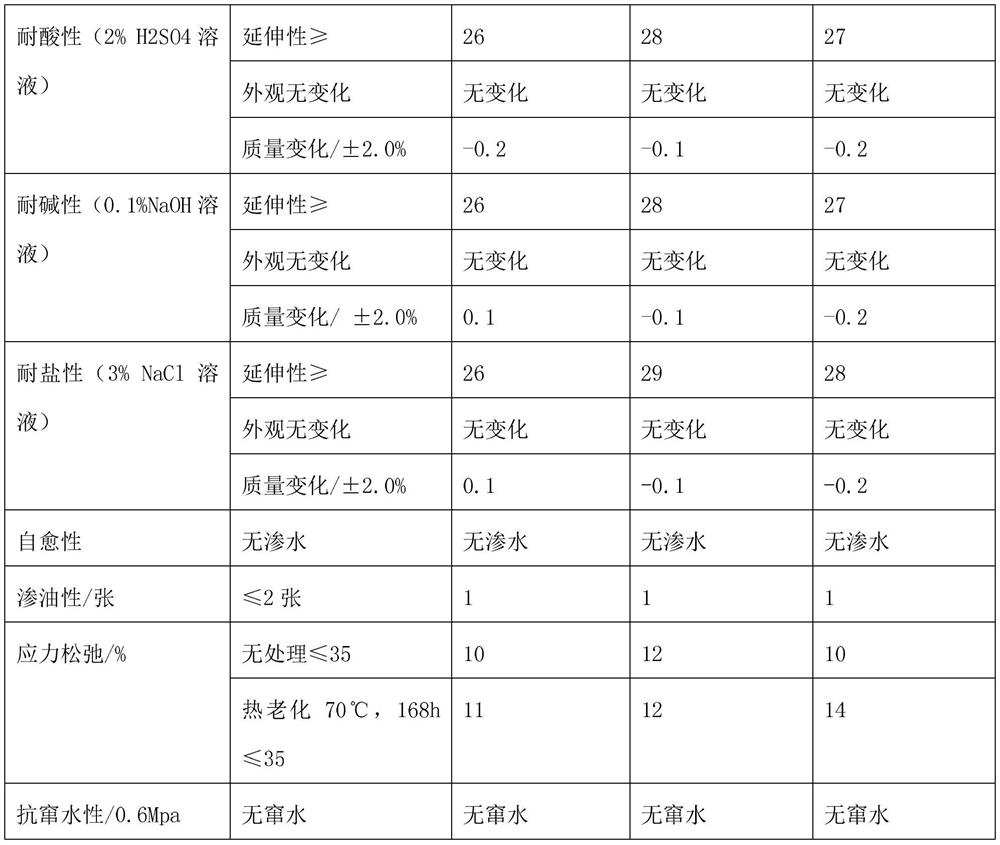

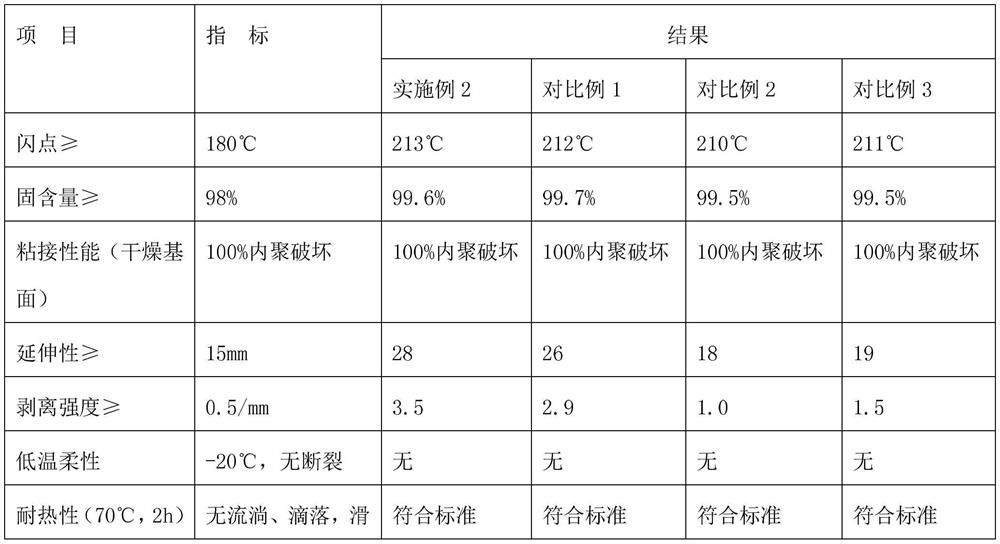

Examples

Embodiment 1

[0021] A creeping viscoelastic rubber waterproof coating, which is made by mixing the following raw materials according to weight percentage: 90# asphalt 30%, thermoplastic styrene-butadiene rubber 20%, butyl rubber 15%, active tackifying resin 10%, rubber oil 12%, silane coupling agent vinyltriethoxysilane 5%, filler light calcium 4%, carbon black 4%; wherein the active tackifying resin is tackifying resin JT-260, alkylphenol acetylene tackifying resin , C5 petroleum resin mixed according to the mass ratio of 1:2:3.

[0022] The production method of the above-mentioned creep type viscoelastic rubber waterproof coating comprises the following steps: adding 90# petroleum asphalt into a reaction kettle with a stirring device according to the weight percentage and raising the temperature to 145°C, and then sequentially adding thermoplastic styrene-butadiene rubber, butyl Stir the rubber and softened oil for 70 minutes, raise the reaction temperature to 160°C, add tackifying resin...

Embodiment 2

[0024] A creeping viscoelastic rubber waterproof coating, which is made by mixing the following raw materials according to weight percentage: 90# asphalt 38%, thermoplastic styrene-butadiene rubber 18%, butyl rubber 16%, active tackifying resin 8%, paraffin oil 7%, coupling agent silane coupling agent aminopropyltriethoxysilane 3%, filler talcum powder 10%; wherein the active tackifying resin is tackifying resin JT-260, alkylphenol acetylene tackifying resin, C5 petroleum resin is mixed according to the mass ratio of 1:2:4.

[0025] The production method of the above-mentioned creep type viscoelastic rubber waterproof coating comprises the following steps: adding 90# petroleum asphalt into a reaction kettle with a stirring device according to the weight percentage and raising the temperature to 165°C, and then sequentially adding thermoplastic styrene-butadiene rubber, butyl Stir the rubber and softened oil for 90 minutes, raise the reaction temperature to 165°C, add tackifyin...

Embodiment 3

[0027]A creeping viscoelastic rubber waterproof coating, which is made by mixing the following raw materials by weight percentage: 90# asphalt 40%, thermoplastic styrene-butadiene rubber 15%, butyl rubber 10%, active tackifying resin 12%, minus three lines Oil 12%, titanate coupling agent, distearoyloxyisopropoxy aluminate 4%, filler lime powder 10%; wherein the active tackifying resin is tackifying resin JT-260, alkylphenol Acetylene tackifying resin and C5 petroleum resin are mixed according to the mass ratio of 1:2:5.

[0028] The production method of the above-mentioned creep type viscoelastic rubber waterproof coating comprises the following steps: adding 90# petroleum asphalt into a reaction kettle with a stirring device according to the weight percentage and raising the temperature to 180°C, and then sequentially adding thermoplastic styrene-butadiene rubber, butyl Mix rubber and softening oil for 100 minutes, raise the reaction temperature to 170°C, add tackifying resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com