Preparation method and application of amidation modified magnetic chitosan microspheres

A chitosan microsphere, amidation technology, applied in chemical instruments and methods, inorganic chemistry, radioactive purification, etc., can solve the problems of adsorption of metal ions, separation of chitosan by adsorption matrix, etc., to achieve enhanced chelation ability, Realize the effect of multiple utilization and good removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

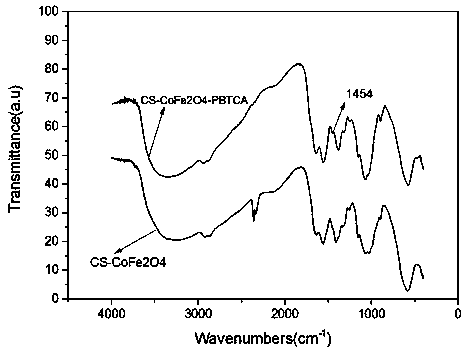

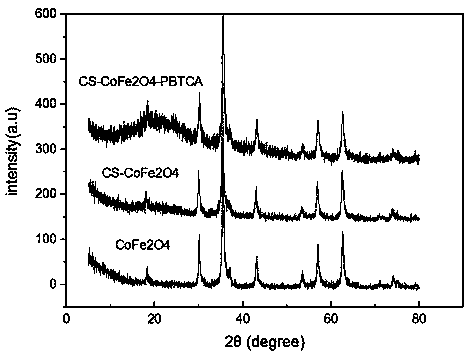

[0029] (1) 5.0mmol Fe(NO 3 ) 3 9H 2 O and 2.5mmol Co(NO 3 ) 2 ·6H 2 Disperse O in 60ml of distilled water, mix and stir for 30-60min, adjust the pH of the solution to 12 with NaOH, stir magnetically for 30-60min, and transfer the mixed solution into a 100ml Teflon-lined reactor. The reaction temperature is 180° C., and the reaction time is 24 hours. After the reaction is completed, wash with deionized water and absolute ethanol, and know that the pH of the supernatant is close to neutral, and freeze-dry at low temperature for 24 hours to obtain dispersed and uniform CoFe particles.2 o 4 nanoparticles.

[0030] (2) 3g chitosan is dissolved in the 2% acetic acid solution of 150ml, is mixed with transparent chitosan solution, the 3g CoFe prepared by step (1) 2 o 4 Disperse the nanoparticles in the above solution, stir evenly, and polymerize by inverse emulsion, add 200ml cyclohexane and 1.1ml Span 80, mix well, add 1ml glutaraldehyde with a mass fraction of 50%, Schiff ba...

Embodiment 2

[0035] Prepare 14 parts of 50ml U(VI) buffer solution with an initial concentration of 100mg / L and divide them into two groups. Each group uses 1mol / L nitric acid or sodium hydroxide to adjust the pH to 1M respectively (M is 1mol / L, the same below) 0.5M, 0.2M, 1, 2, 3, 4. Get wherein one group of buffer solution, in the buffer solution of this group of different pH values, add respectively the amidated modified magnetic chitosan microsphere that 0.05g embodiment 1 makes; Get another group of buffer solution, add to this group of different pH The prepared magnetic chitosan microspheres were added to the buffer solution of the value. Then, place the two groups of buffer solutions in a constant temperature oscillator in a water bath, keep the temperature at 25°C, and rotate at 150r / min. After shaking for 10 hours, use a magnet to place the amidated modified magnetic chitosan microspheres or Microspheres are separated from wastewater to complete the treatment of U(VI). The unads...

Embodiment 3

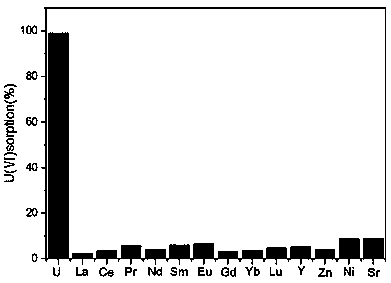

[0040] Thirteen elements from lanthanides, actinides and transition metals were selected as competing ions. The competing ion is: La 3+ 、Ce 3+ 、Pr 3+ 、Nd 3+ 、Sm 3+ 、Eu 3+ 、Gd 3+ , Yb 3+ 、Lu 3+ , Y 3+ , Zn 2+ 、Ni 2+ 、Sr 2+ . Make U(VI) and the other 13 ions coexist at an equal mass concentration (100 mg / L), and adjust the pH of the mixture containing U(VI) and the other 13 ions to 4.0. Get 50ml of the mixed solution, add 0.05g of the amidated modified magnetic chitosan microspheres prepared in Example 1 to the mixed solution, then place the buffer solution in a water bath constant temperature oscillator, keep the temperature at 25°C, and After shaking at 150r / min for 10 hours, use a magnet to separate the amidated modified magnetic chitosan microspheres or magnetic chitosan microspheres from the wastewater to complete the treatment of the mixed solution. The content of 14 kinds of metal ions that were not adsorbed in the wastewater was measured with an inductively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com