Bioactive bone repair scaffold and preparation method thereof

A bioactive, bone repair technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problem that cartilage and subchondral bone cannot be repaired together, reduce cartilage degradation damage, excellent mechanical properties controllability, biological The effect of security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A bioactive bone repair scaffold. The bioactive bone repair scaffold uses a degradable polymer as a matrix, lithium magnesium silicate and magnesium as a reinforcing phase, and includes:

[0043] Lithium magnesium silicate 5%,

[0044] Magnesium 10%,

[0045] Degradable polymer 85%.

[0046] in:

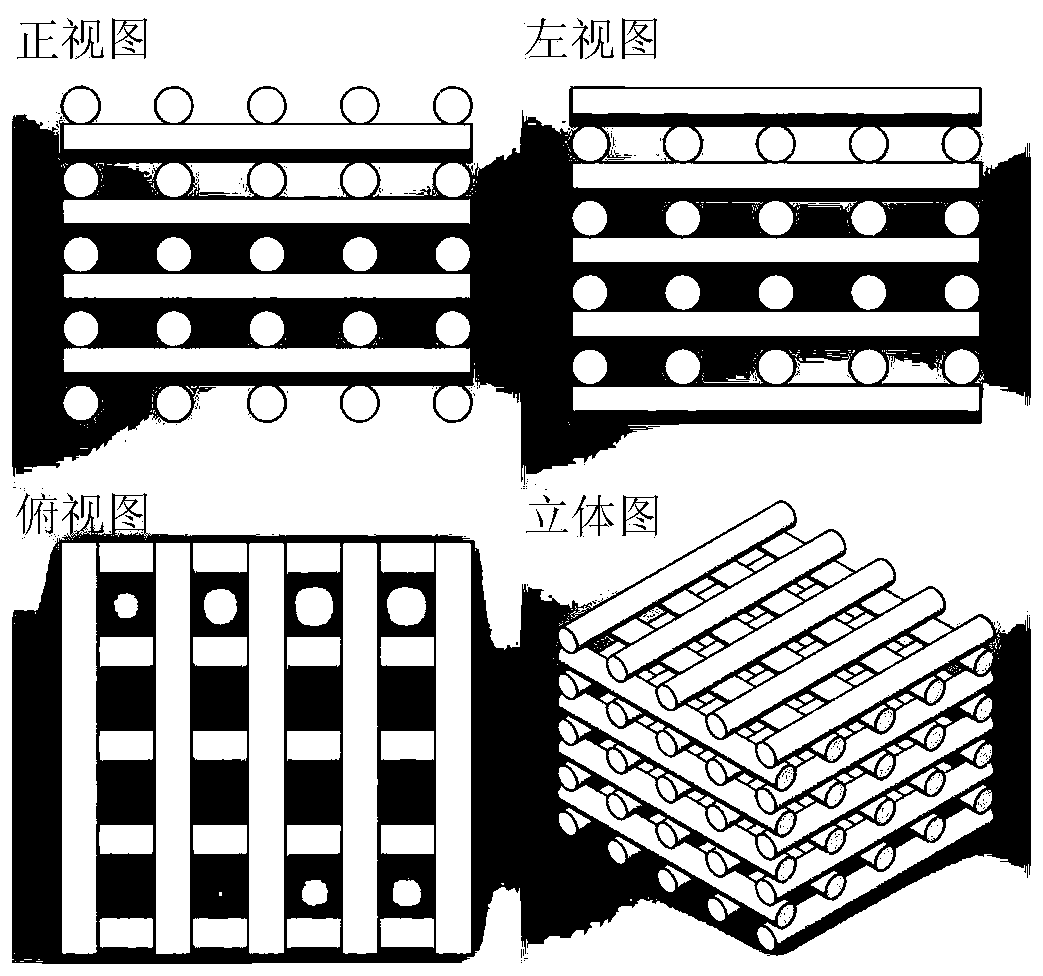

[0047] The bioactive bone repair scaffold is a through-hole porous scaffold with a porosity of 85% and a pore diameter of 800 μm.

[0048] The magnesium and magnesium-lithium silicate are both granular reinforcing phases, wherein the magnesium-lithium silicate is a powder with a particle size of 50-100 μm, and the magnesium powder is a high-purity magnesium powder with magnesium ≥ 99.8 wt%, in a regular spherical shape, with a particle size of less than 40 μm .

[0049] The degradable polymer is powdery D-polylactic acid PDLA.

[0050] Its preparation steps are as follows:

[0051] S1. Pre-gel: Weigh 0.5g of magnesium lithium silicate powder, add it to 1L of deionized wa...

Embodiment 2

[0057] A bioactive bone repair scaffold. The bioactive bone repair scaffold uses a degradable polymer as a matrix, lithium magnesium silicate and magnesium as a reinforcing phase, and includes:

[0058] Lithium Magnesium Silicate 10%,

[0059] Magnesium 20%,

[0060] Degradable polymer 70%.

[0061] in:

[0062] The bioactive bone repair scaffold is a through-hole porous scaffold with a porosity of 80% and a pore diameter of 700 μm.

[0063] The magnesium and magnesium-lithium silicate are both granular reinforcing phases, wherein the magnesium-lithium silicate is a powder with a particle size of 50-100 μm, and the magnesium powder is a high-purity magnesium powder with magnesium ≥ 99.8 wt%, in a regular spherical shape, with a particle size of less than 40 μm .

[0064] The degradable polymer is powdered polycaprolactone PCL.

[0065] Its preparation steps are as follows:

[0066] S1. Pre-gel: Weigh 1.0g of lithium magnesium silicate powder, add it to 1L of deionized wa...

Embodiment 3

[0072] A bioactive bone repair scaffold. The bioactive bone repair scaffold uses a degradable polymer as a matrix, lithium magnesium silicate and magnesium as a reinforcing phase, and includes:

[0073] Lithium Magnesium Silicate 12%,

[0074] Magnesium 24%

[0075] Degradable polymer 64%.

[0076] in:

[0077] The bioactive bone repair scaffold is a through-hole porous scaffold with a porosity of 75% and a pore diameter of 600 μm.

[0078] The magnesium and magnesium-lithium silicate are both granular reinforcing phases, wherein the magnesium-lithium silicate is a powder with a particle size of 50-100 μm, and the magnesium powder is a high-purity magnesium powder with magnesium ≥ 99.8 wt%, in a regular spherical shape, with a particle size of less than 40 μm .

[0079] The degradable polymer is powdered poly-L-lactic acid PLLA.

[0080] Its preparation steps are as follows:

[0081] S1. Pre-gel: Weigh 1.2g of lithium magnesium silicate powder, add it to 1L of deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com