High-temperature heat insulation fire-resistant fiber, fabric, preparation method and application

A flame-retardant fiber and high-temperature technology, which is applied in the field of preparation of heat-insulating flame-retardant fibers, can solve the problems of restricting the application of porous fibers and the inability to realize continuous large-scale preparation, and achieve excellent high-temperature heat insulation and flame-retardant properties, preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

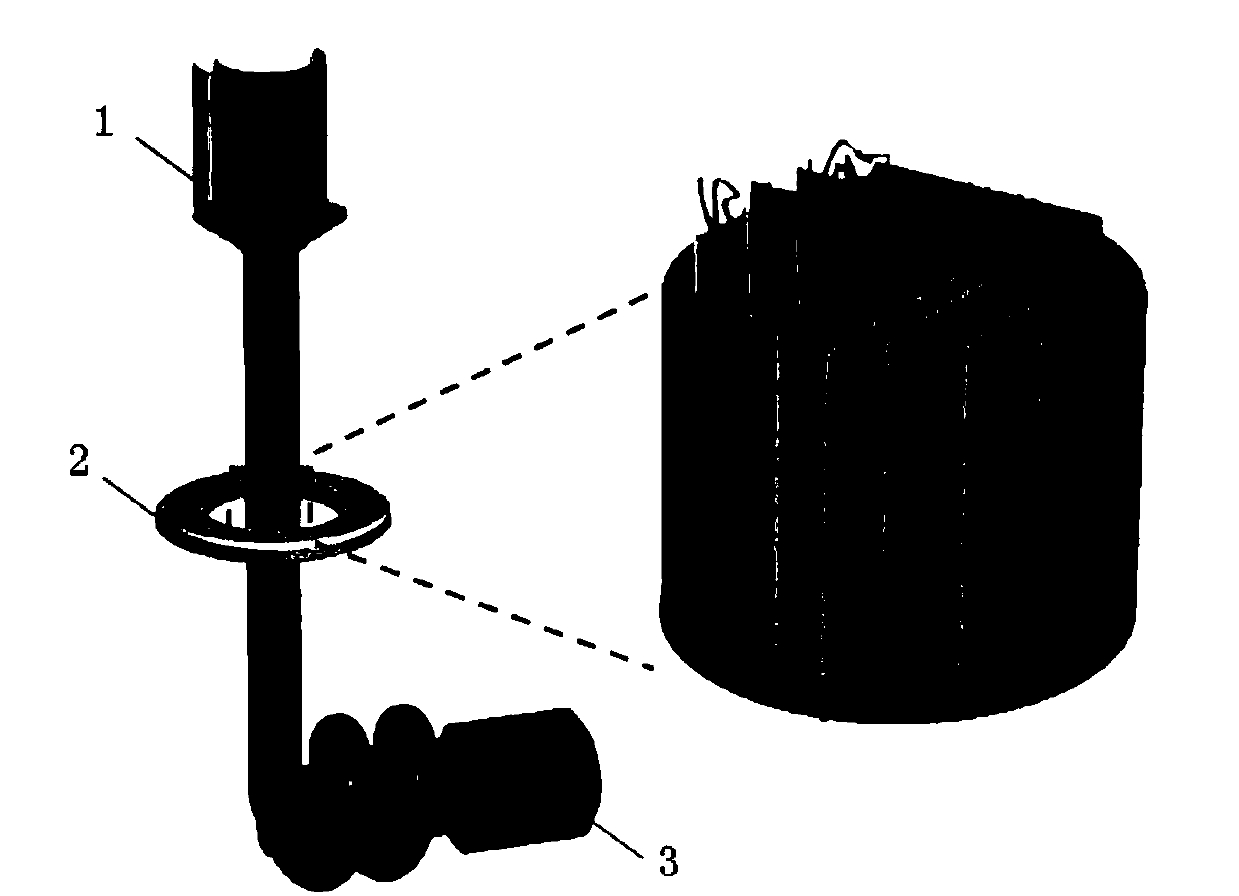

Image

Examples

Embodiment 1

[0048] Embodiment 1: Preparation of polyamic acid salt hydrogel

[0049] (1) Fully stir 8.0096g ODA (4,4'-diaminodiphenyl ether) and 95.57g DMAc (dimethylacetamide), when ODA is completely dissolved, then add 8.8556g PMDA (pyromellitic acid diphenyl ether) Anhydride) and 4.0476g TEA (triethylamine), mixed and stirred for 4 hours to produce a viscous pale yellow PAS (polyamic acid salt) solution. The PAS solution was slowly poured into water, washed, and freeze-dried to obtain a pale yellow PAS solid.

[0050] (2) 5 g of TEA (triethylamine) and 90 g of deionized water were added to 5 g of PAS, and the resulting suspension was continuously stirred for several hours, mixed evenly and left to stand for 24 h to obtain a 5% PAS hydrogel.

Embodiment 2

[0051] Embodiment 2: Preparation of polyamic acid salt hydrogel

[0052] Prepare with reference to Example 1, the difference is that step (2) adds 5g TEA (triethylamine) and 85g deionized water to 10g PAS, the resulting suspension is stirred continuously for several hours, after mixing evenly, stand still for 24h to obtain the mass Fractions are 10% PAS hydrogels.

Embodiment 3

[0053] Embodiment 3: Preparation of polyamic acid salt hydrogel

[0054] Prepare with reference to Example 1, the difference is that in step (2) add 5gTEA (triethylamine) and 80g deionized water to 15g PAS, the resulting suspension is stirred continuously for several hours, after mixing evenly, stand still for 24h to obtain the mass fraction 15% PAS hydrogel.

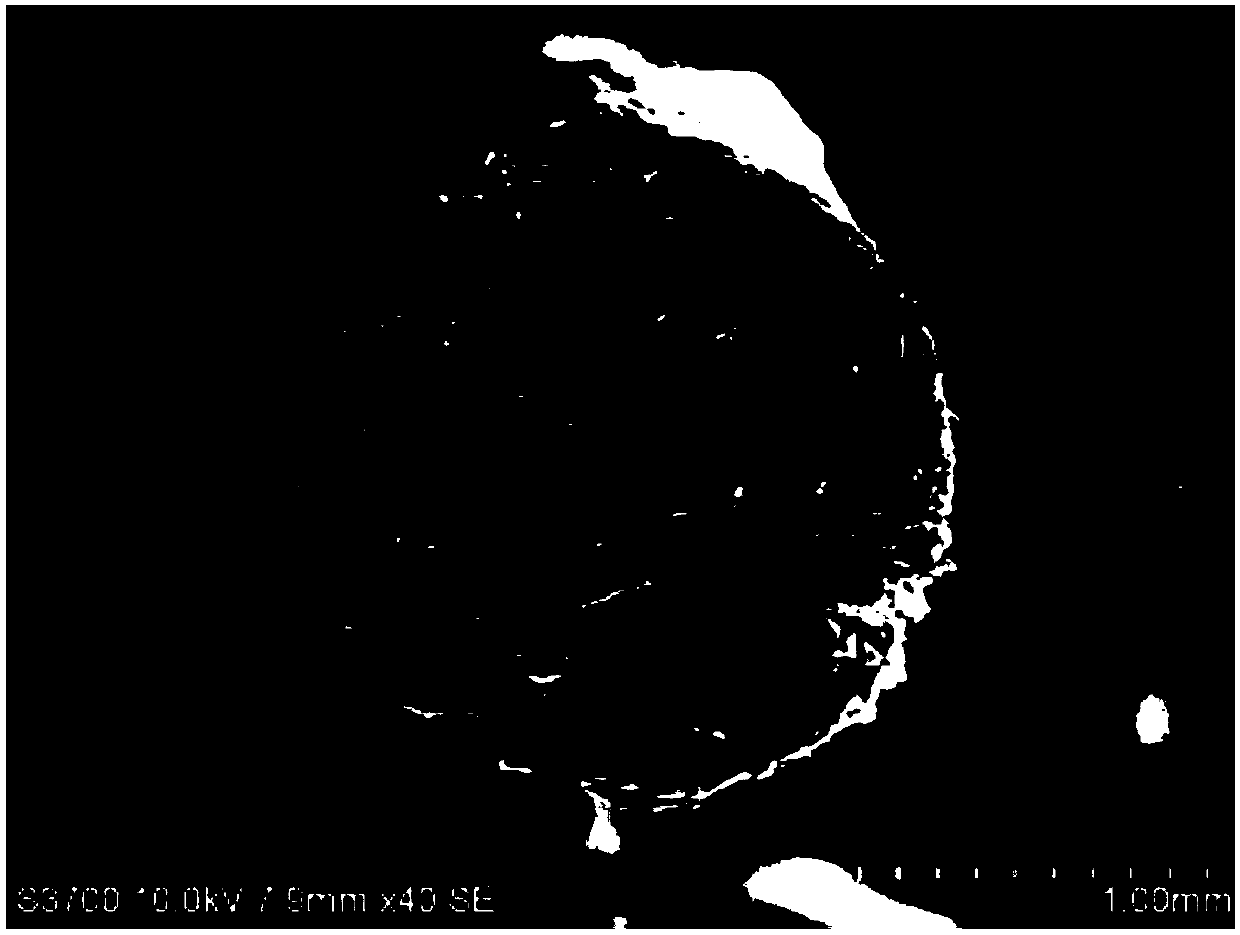

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com