Anti-counterfeiting label material with double-mode light emitting function, preparation method and application thereof

An anti-counterfeit label and dual-mode technology, applied in the field of phosphorescent materials, achieves the effects of good repeatability, large adjustment range, and large range of luminescent colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

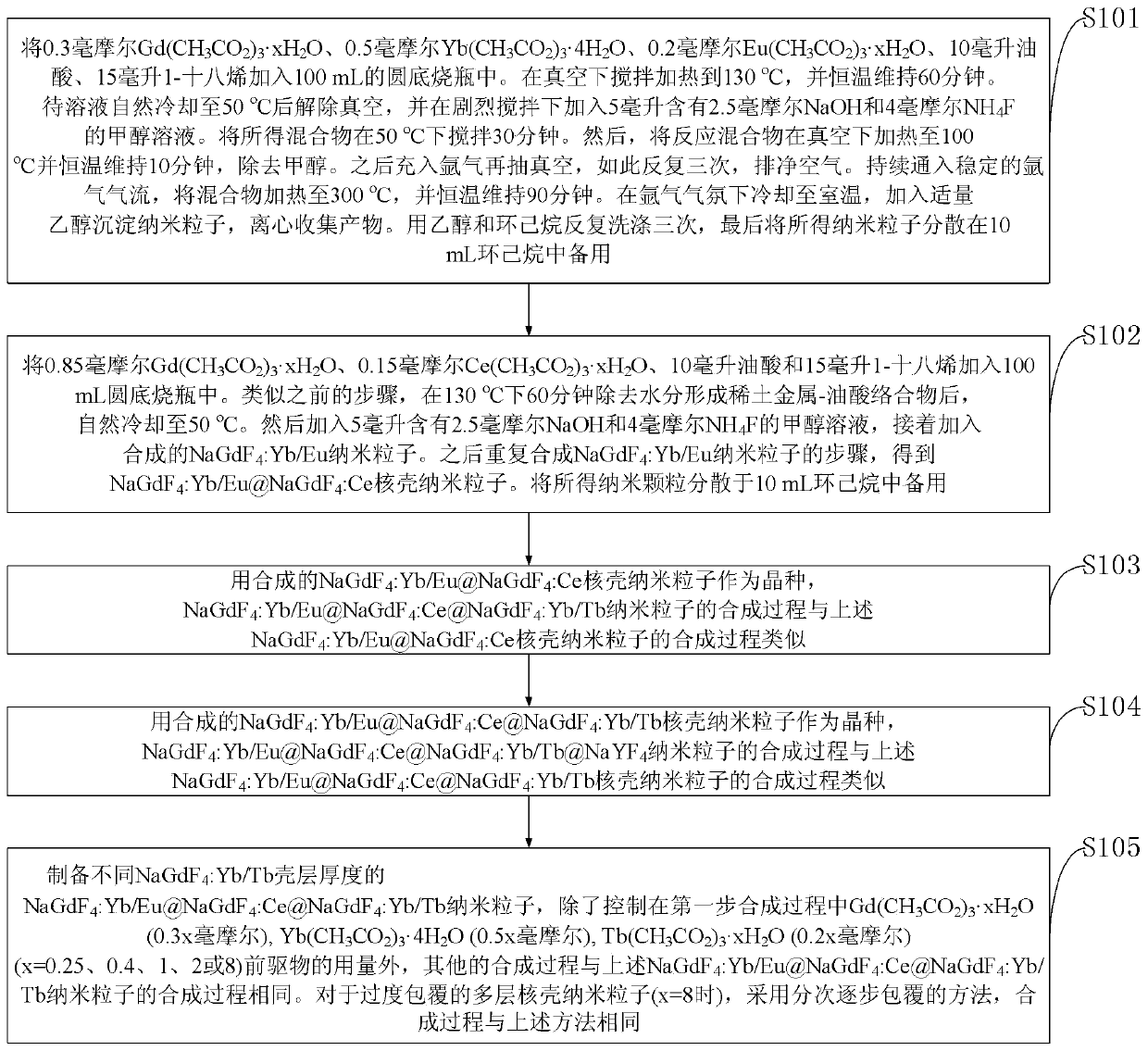

[0062] like figure 1 As mentioned above, the preparation method of the anti-counterfeiting label material with dual-mode luminescence provided by the embodiment of the present invention includes the following steps:

[0063] S101, 0.3 mmol Gd(CH 3 CO 2 ) 3 ·xH 2 O, 0.5 mmol Yb(CH 3 CO 2 ) 3 4H 2 O, 0.2 mmol Eu(CH 3 CO 2 ) 3 ·xH 2 O. Add 10 milliliters of oleic acid and 15 milliliters of 1-octadecene into a 100-mL round bottom flask. Stir and heat to 130° C. under vacuum, and keep the temperature constant for 60 minutes. After the solution was naturally cooled to 50°C, the vacuum was released, and 5 ml of NaOH containing 2.5 mmol and 4 mmol of NH were added under vigorous stirring. 4 F in methanol solution. The resulting mixture was stirred at 50°C for 30 minutes. The reaction mixture was then heated to 100° C. under vacuum and held at a constant temperature for 10 minutes to remove methanol. Then fill it with argon and then evacuate it, and repeat this three ti...

Embodiment 1

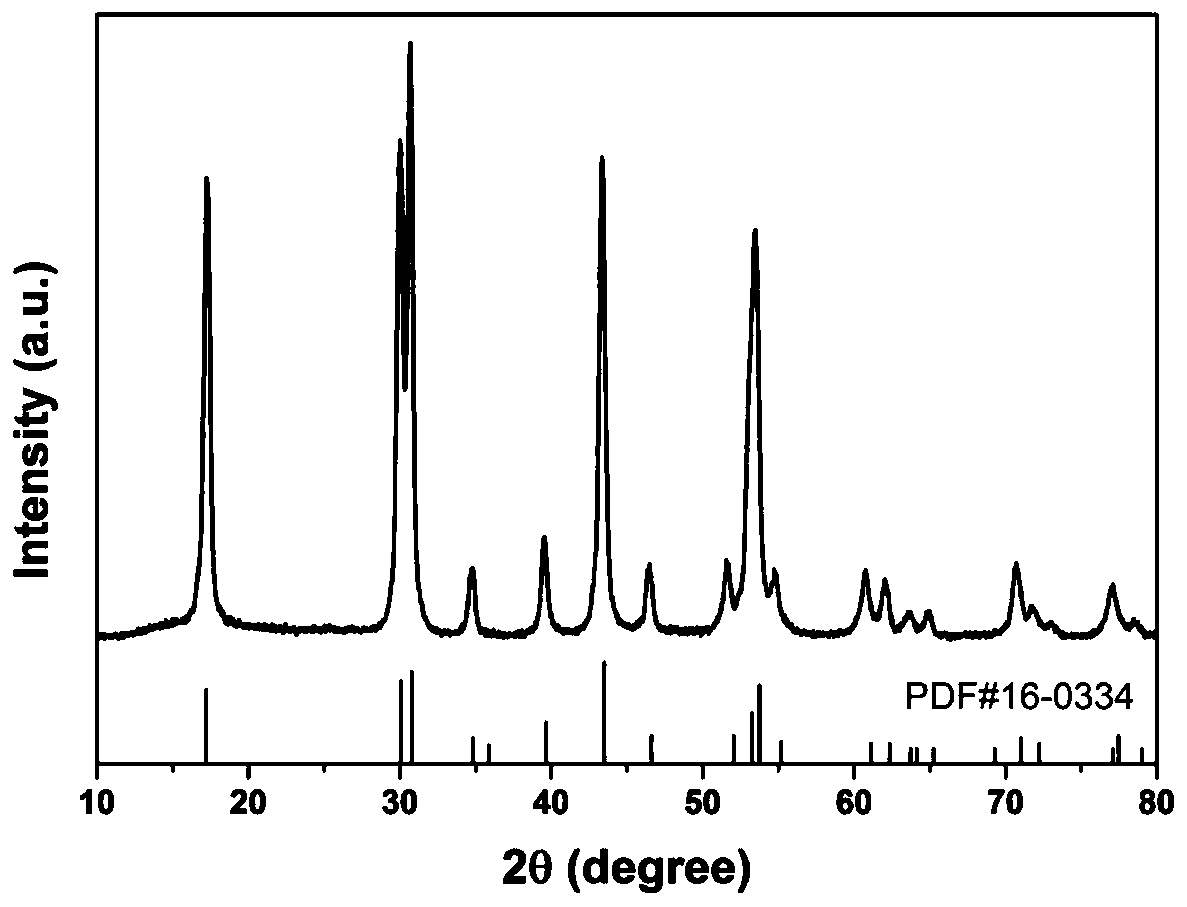

[0078] The chemical formula of the anti-counterfeiting label material of the present invention is NaGdF 4 :0.50Yb / 0.20Eu@NaGdF 4 :0.15Ce@NaGdF 4 :0.50Yb / 0.20Tb@NaYF 4 . The concentrations of rare earth ions involved do not limit the scope of the invention.

Embodiment 2

[0080] The present invention adopts thermal decomposition method, 0.3 millimolar Gd (CH 3 CO 2 ) 3 ·xH 2 O, 0.5 mmol Yb(CH 3 CO 2 ) 3 4H 2 O, 0.2 mmol Eu(CH 3 CO 2 ) 3 ·xH 2 O. Add 10 milliliters of oleic acid and 15 milliliters of 1-octadecene into a 100-mL round bottom flask. Stir and heat to 130° C. under vacuum, and keep the temperature constant for 60 minutes. After the solution was cooled to 50°C, the vacuum was released, and 5 ml of NaOH containing 2.5 mmol and 4 mmol of NH were added under vigorous stirring. 4 F in methanol solution. The resulting mixture was stirred at 50°C for 30 minutes. The reaction mixture was then heated to 100° C. under vacuum and held at a constant temperature for 10 minutes to remove methanol. Then fill it with argon and then evacuate it, and repeat this three times to exhaust the air. The mixture was heated to 300° C. under a constant flow of argon gas and maintained at a constant temperature for 90 minutes. Cool to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com