Monolithic composite porous carbon adsorption material for separating methane and nitrogen, and preparation method thereof

An adsorption material and methane separation technology, applied in the field of monolithic composite porous carbon adsorption material and its preparation, can solve the problems of low methane adsorption capacity, poor separation selectivity, complex preparation process, etc., achieve high adsorption capacity, increase adsorption capacity, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

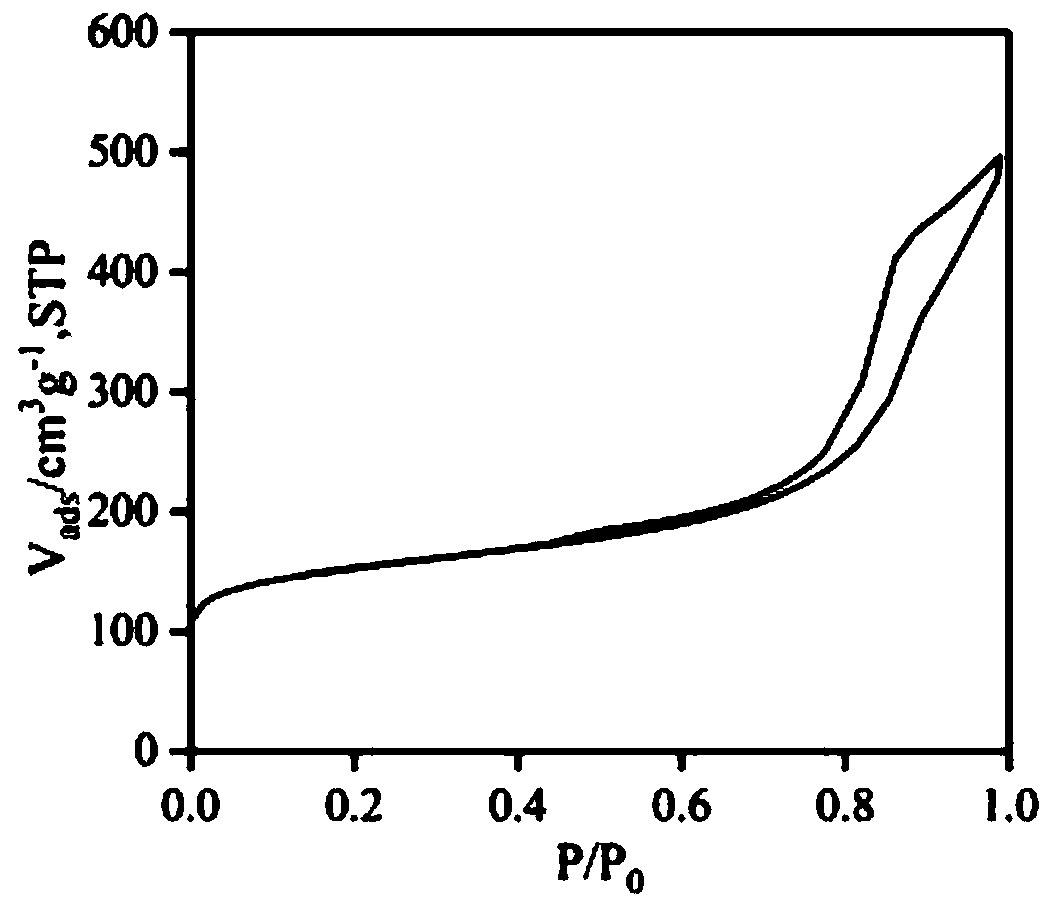

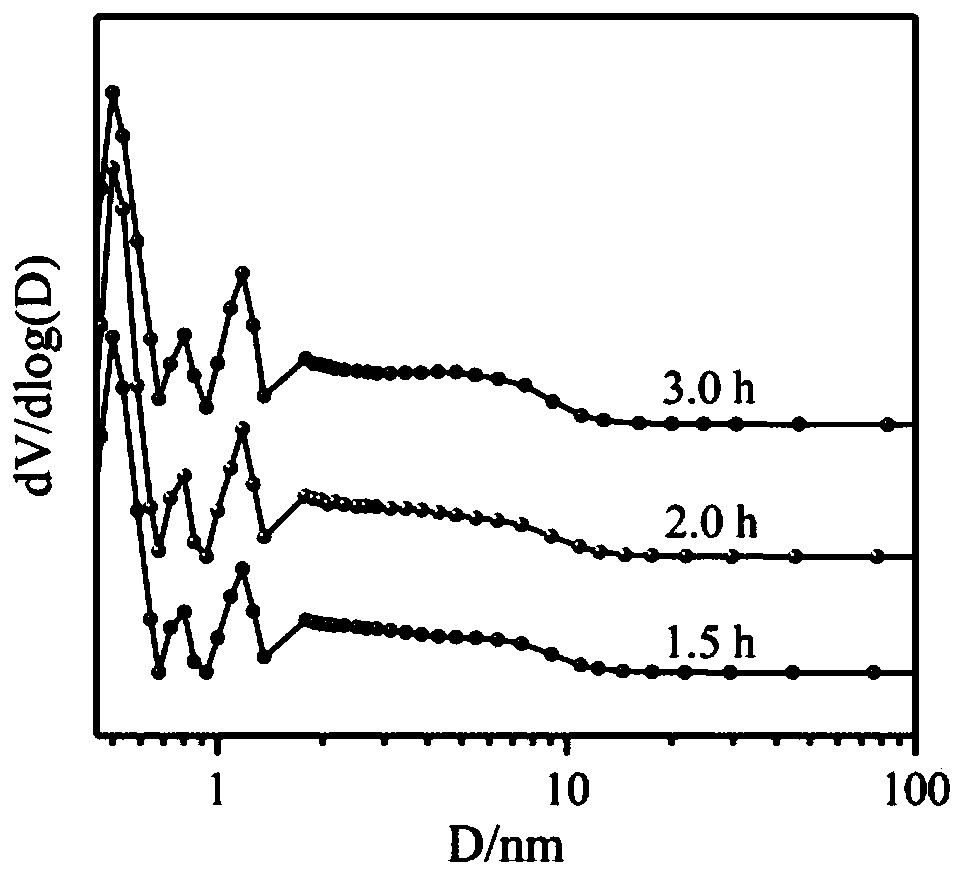

[0041] Weigh 0.5g lithium alginate, add it to 156mL deionized water, stir at room temperature until it dissolves evenly; then, weigh 9.0g resorcinol and add it to the above solution, stir until dissolved; measure 12mL of formaldehyde solution (37wt.%) was quickly added to the above solution, and after continuing to stir for a certain period of time; the above solution was poured into a quartz tube reactor, and transferred to a 90°C constant temperature oven for gel aging for 18 hours; after aging, the polymer was taken out and completely dried Save for later. Under the purging of argon atmosphere, the temperature was raised from room temperature to 800°C at a rate of 3°C / min. At this time, the argon atmosphere was switched to an activated carbon dioxide atmosphere, and activated for 1.5h to obtain a composite porous carbon (monolithic composite porous carbon carbon adsorbent). Such as figure 1 As shown, the nitrogen adsorption test results show that its BET specific surface ...

Embodiment 2

[0044] The polymer prepared in Example 1 was placed in a carbonization furnace, and the temperature was raised from room temperature to 800°C at a rate of 3°C / min. At this time, the argon atmosphere was switched to an activated carbon dioxide atmosphere and activated for 2 hours to obtain a composite porous carbon. Nitrogen adsorption test results show that its BET specific surface area is about 1060m 2 g -1 , the micropore volume is about 0.27cm 3 g -1 , the micropore size distribution is as figure 2 shown.

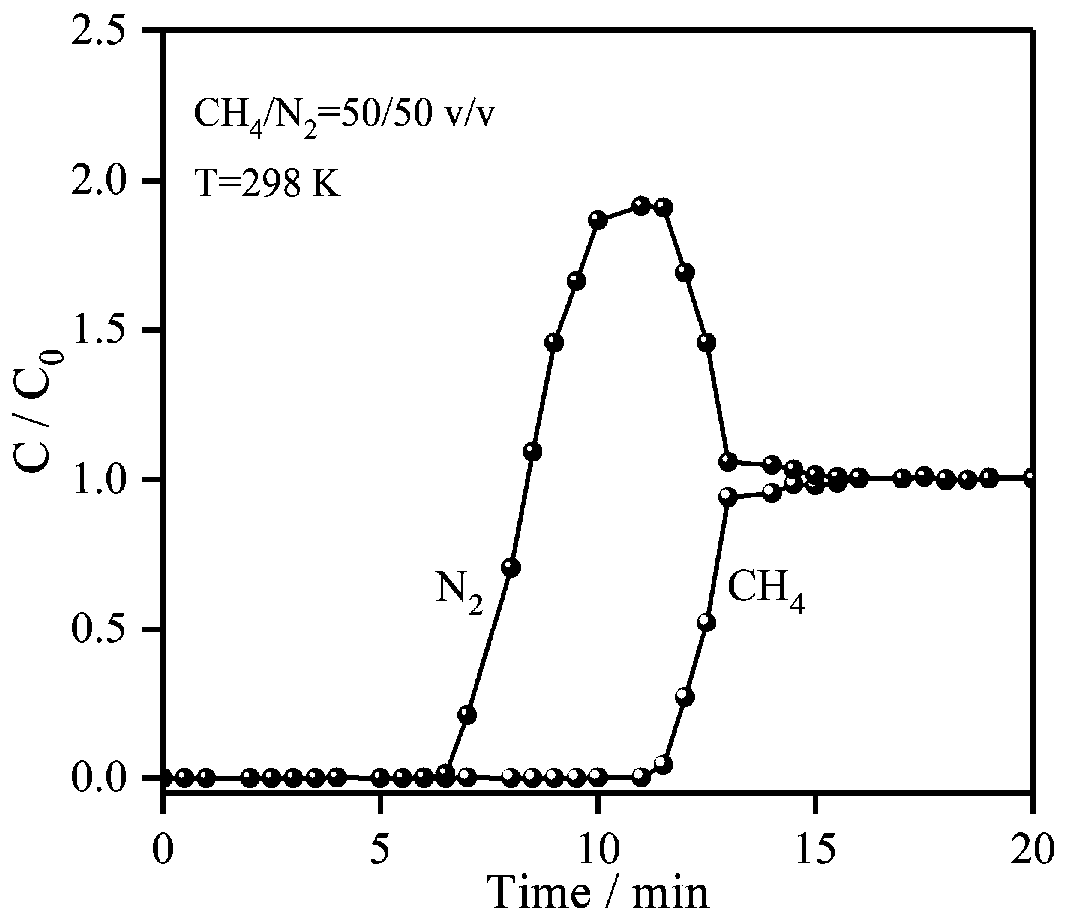

[0045] In order to test the separation performance of the monolithic composite porous carbon synthesized above for methane and nitrogen, its separation performance for methane and nitrogen was evaluated on a fixed bed device, and the separation conditions were as follows: test temperature 25°C; normal pressure; inert gas purge desorption The volume percentage of methane and nitrogen is 50%, and the total flow of methane and nitrogen is 12mL / min; product analysis ado...

Embodiment 3

[0047] The polymer prepared in Example 1 was placed in a carbonization furnace, and the temperature was raised from room temperature to 800°C at a rate of 3°C / min. At this time, the argon atmosphere was switched to an activated carbon dioxide atmosphere and activated for 3 hours to obtain a composite porous carbon. Nitrogen adsorption test results show that its BET specific surface area is about 1166m 2 g -1 , the micropore volume is about 0.30cm 3 g -1 , the micropore size distribution is as figure 2 shown.

[0048] In order to test the separation performance of the monolithic composite porous carbon synthesized above for methane and nitrogen, its separation performance for methane and nitrogen was evaluated on a fixed bed device, and the separation conditions were as follows: test temperature 25°C; normal pressure; inert gas purge desorption The volume percentage of methane and nitrogen is 50%, and the total flow of methane and nitrogen is 12mL / min; product analysis ado...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com