Composition for regulating sebum secretion amount and preparation method thereof

A technology of sebum secretion and composition, which is applied in the field of composition for regulating sebum secretion and its preparation, can solve the problems of reducing oil secretion, and achieve the effects of regulating sebum secretion, stimulating pore shrinkage, and controlling oil secretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

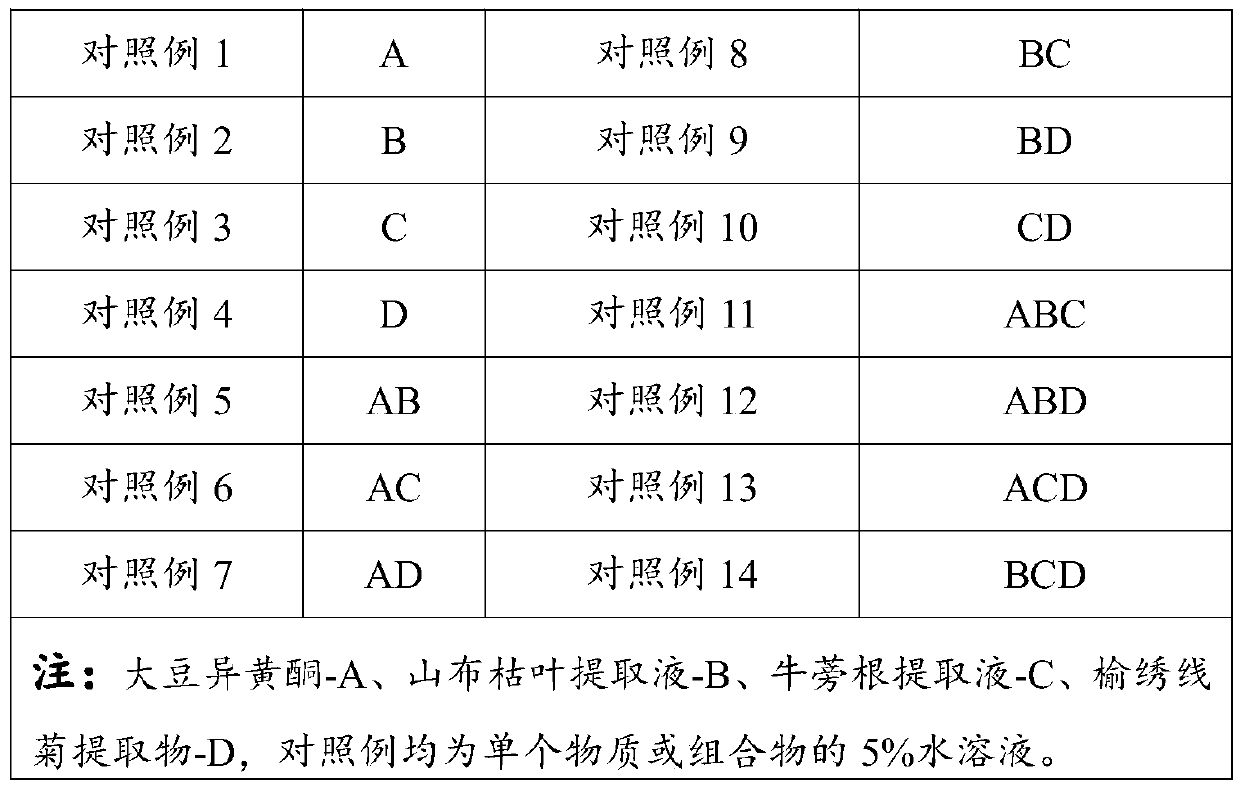

Examples

Embodiment 1

[0041] 1. Preparation of raw materials

[0042] (1) The extraction method of soybean isoflavones comprises the following steps:

[0043] 1) Raw material processing: crush the soybean meal to a particle size of 0.5 mm, and set aside;

[0044]2) Solvent extraction: extract the soybean meal obtained in step 1) with an aqueous ethanol solution with a concentration of 80%, the ratio of material to solvent is 1g:8mL, the extraction temperature is 80°C, the extraction time is 5h, and the number of extractions is 3 times to obtain the extract;

[0045] 3) Separation: after centrifuging the extract obtained in step 2), drying the obtained solvent extract for 10 hours;

[0046] 4) Refining: Use ultrafiltration membrane combined with adsorption resin to remove some impurities with ultrafiltration membrane. The cutting molecular weight of ultrafiltration membrane is 600. Soybean isoflavones in the extract;

[0047] 5) Desorption and drying: after adsorption by the adsorption resin, de...

Embodiment 2

[0068] 1. Preparation of raw materials

[0069] (1) The extraction method of soybean isoflavones comprises the following steps:

[0070] 1) Raw material processing: crush the soybean meal to a particle size of 0.8mm, and set aside;

[0071] 2) Solvent extraction: Extract the soybean meal obtained in step 1) with 40% ethanol aqueous solution, the ratio of material to solvent is 1g:16mL, the extraction temperature is 60°C, the extraction time is 10h, and the number of extractions is 1 times to obtain the extract;

[0072] 3) Separation: after centrifuging the extract obtained in step 2), drying the obtained solvent extract for 5 hours;

[0073] 4) Refining: Use ultrafiltration membrane combined with adsorption resin to remove some impurities. The cut molecular weight of the ultrafiltration membrane is 100,000. Soybean isoflavones in the extract;

[0074] 5) Desorption and drying: after adsorption by the adsorption resin, desorption is carried out with a desorption solution, ...

Embodiment 3

[0095] 1. Preparation of raw materials

[0096] (1) The extraction method of soybean isoflavones comprises the following steps:

[0097] 1) Raw material processing: crush the soybean meal to a particle size of 0.6 mm, and set aside;

[0098]2) Solvent extraction: the soybean meal obtained in step 1) was extracted with 60% ethanol aqueous solution, the solid-liquid ratio of raw material and solvent was 1g:12mL, the extraction temperature was 70°C, the extraction time was 6h, and the extraction times were 2 times to obtain the extract;

[0099] 3) Separation: after centrifuging the extract obtained in step 2), drying the obtained solvent extract for 8 hours;

[0100] 4) Refining: use the combination of ultrafiltration membrane and adsorption resin to remove some impurities. The cut molecular weight of the ultrafiltration membrane is 5000. Soybean isoflavones in the extract;

[0101] 5) Desorption and drying: after adsorption by the adsorption resin, desorption is carried out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com