Preparation method of nanometer bimodal isomeric aluminum-magnesium alloy

A kind of aluminum-magnesium alloy and nano-technology, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve the problems of large strength difference, complex reaction, high cost, etc., to facilitate post-processing, high repeatability, and high molding rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

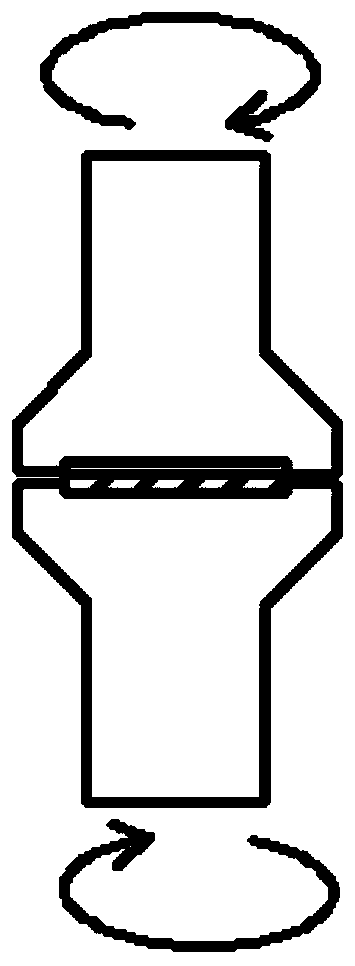

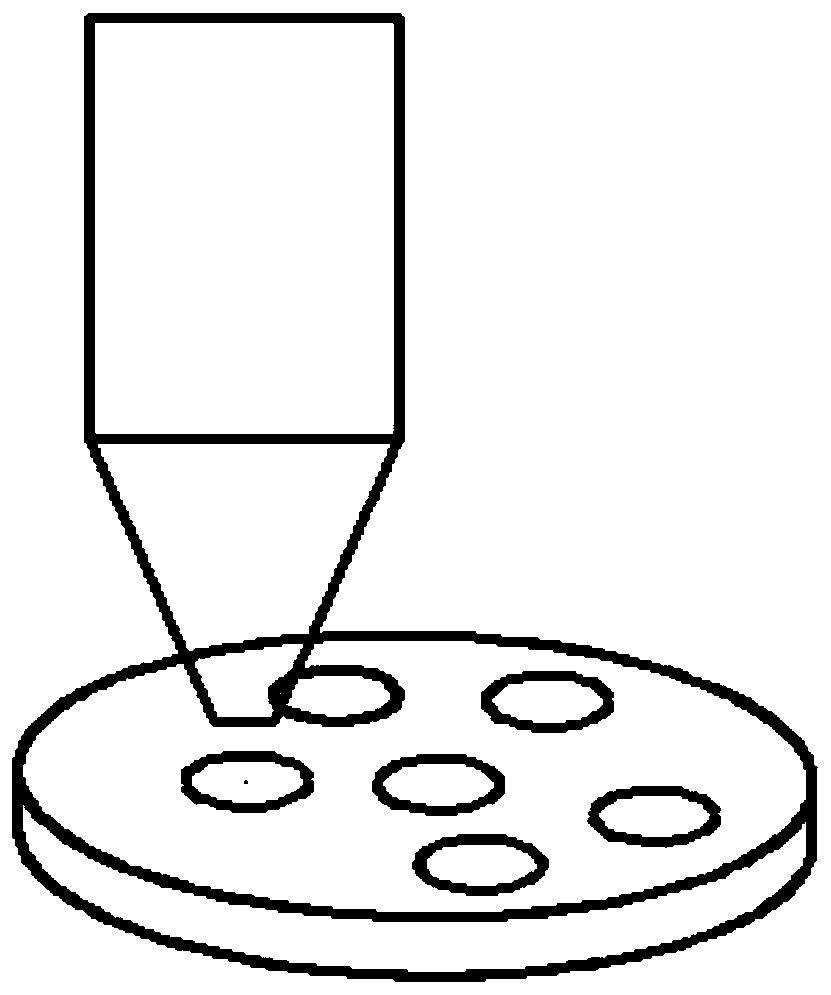

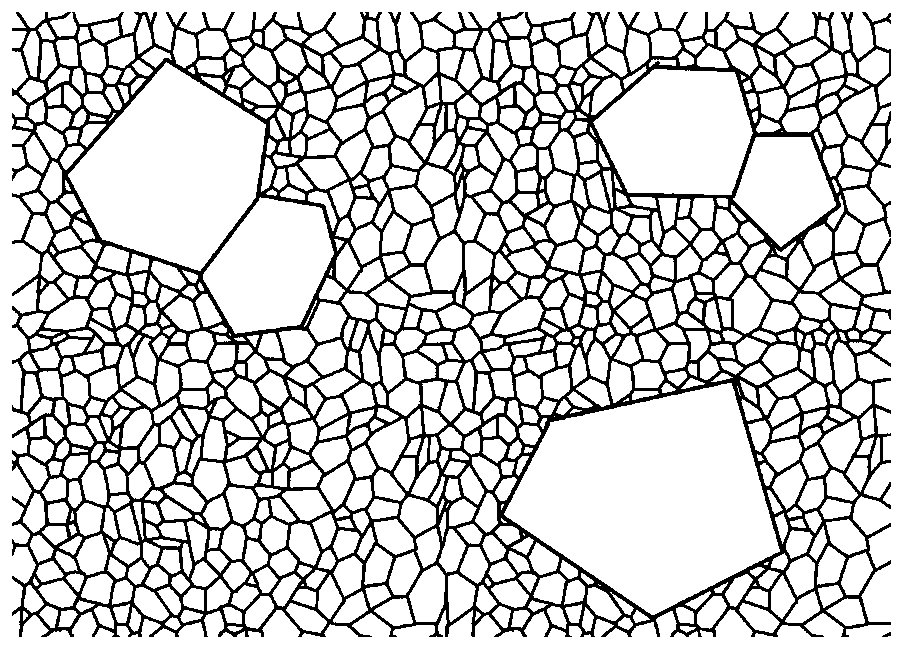

[0035] A method for preparing a nanocrystalline / coarse-crystalline bimodal structure Al-Mg alloy, the mass percentage of the material is: 5-7wt% Mg, the rest is Al, and the specific steps are as follows:

[0036] Step 1: Material selection + casting: select the alloy composition, and cast it into a block material; the casting temperature is 680--710°C;

[0037] Step 2: Homogenization: Homogenize the cast alloy bulk material in Step 1 at a temperature range of 300-450° C. for 16-20 hours to prepare a bulk material with more uniform grain size.

[0038] Step 3: Hot deformation: hot rolling the bulk material obtained in step 2 at a temperature of 280-320° C., with a down-rolling rate of 40%-60%, to form a new alloy bulk material. Since defects such as porosity and shrinkage are prone to occur during the casting process, the use of thermal deformation can effectively reduce such defects and make the basic properties of the alloy more stable;

[0039] Step 4: solid solution + quen...

Embodiment 1

[0044] Embodiment 1: Preparation of Al-Mg nano bimodal heterogeneous alloy

[0045] Alloy composition (mass percentage): 5%-Mg, 95%-Al.

[0046] Preparation process: (1) Pure aluminum block (purity 99.9999%) and magnesium block (purity 99.99%) are selected. The aluminum block and the magnesium block are respectively melted to liquid state by using a vacuum melting furnace, and then the molten liquid is injected into the casting mold together, and the two metal liquids are fully fused by electromagnetic stirring, and finally the aluminum-magnesium alloy block is obtained. (2) Homogenize the cast alloy block at a temperature of 350° C. for 20 hours to make the grain size more uniform. (3) Hot-rolled at a temperature of 280-320°C, since defects such as porosity and shrinkage are prone to occur during the casting process, the use of thermal deformation can effectively reduce such defects and make the basic properties of the alloy more stable; (4) in Solid solution at 450°C for 1...

Embodiment 2

[0048] Embodiment 2: Preparation of Al-Mg nano bimodal heterogeneous alloy

[0049] Alloy composition (mass percentage): 7%-Mg, 93%-Al.

[0050] Preparation process: (1) Pure aluminum block (purity 99.9999%) and magnesium block (purity 99.99%) are selected. The aluminum block and the magnesium block are respectively melted to liquid state by using a vacuum melting furnace, and then the molten liquid is injected into the casting mold together, and the two metal liquids are fully fused by electromagnetic stirring, and finally the aluminum-magnesium alloy block is obtained. (2) Homogenize the cast alloy block at a temperature of 350° C. for 20 hours to make the grain size more uniform. (3) Hot-rolled at a temperature of 280-320°C, since defects such as porosity and shrinkage are prone to occur during the casting process, the use of thermal deformation can effectively reduce such defects and make the basic properties of the alloy more stable; (4) in Solid solution at 450°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com