High-temperature-resistant immersion probe for laser-induced breakdown spectroscopy system

A laser-induced breakdown and spectroscopy system technology, applied in the field of high temperature immersion probes, can solve problems such as lack, and achieve the effects of easy use and maintenance, reduced size, and reduced burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

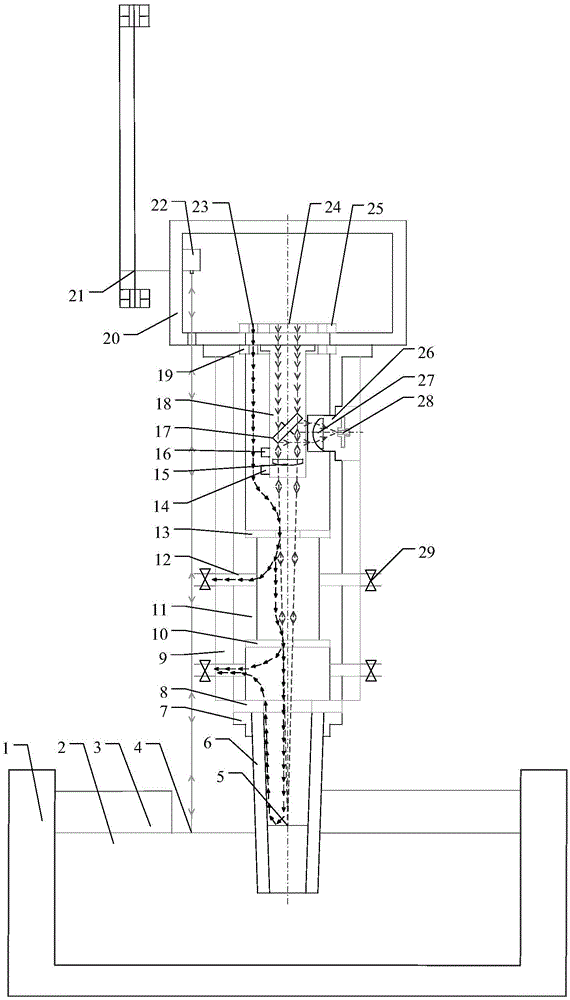

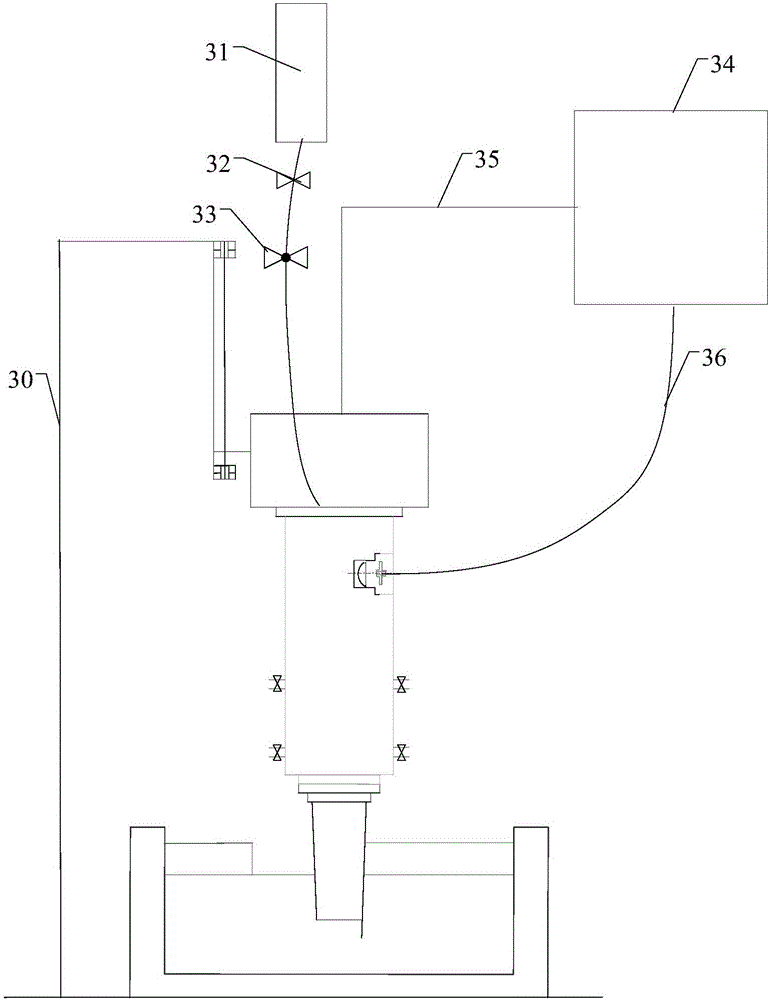

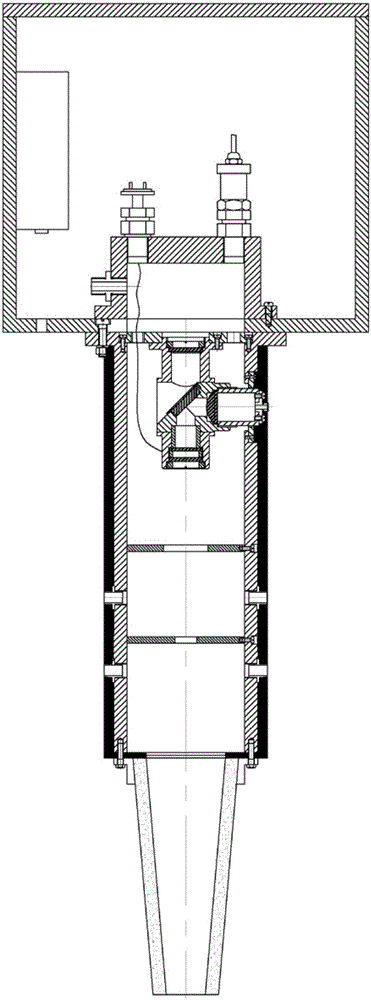

[0017] The invention provides a high-temperature-resistant immersion probe for laser-induced breakdown spectroscopy system, the principle diagram of which is as follows figure 1 and figure 2 shown. The high temperature resistant pipe 6 is responsible for passing through the slag layer 3 and immersing in the high temperature melt 2; the high temperature resistant pipe sleeve 7 is used to clamp the high temperature resistant pipe 6; the heat shield 8 is used to block the heat transfer from the high temperature resistant pipe 6 to the intermediate protection pipe 11; The outer heat insulation layer 9 is responsible for blocking the radiation heat transfer from the surface of the outer melt 2 to the protective tube 11; the protective tube 11 is used to support the entire probe structure, and has several cooling gas outlets 12; the lower beam open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com