Tensile strength 800-MPa-class hot rolling complex phase steel and production method thereof

A technology of tensile strength and production method, which is applied in the field of hot-rolled multiphase steel with a tensile strength of 800 MPa and its production field, can solve the problems of poor surface quality of hot-rolled multiphase steel with high tensile strength, etc., and achieve the effect of increasing precipitation strengthening. , excellent strength, distribution and dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

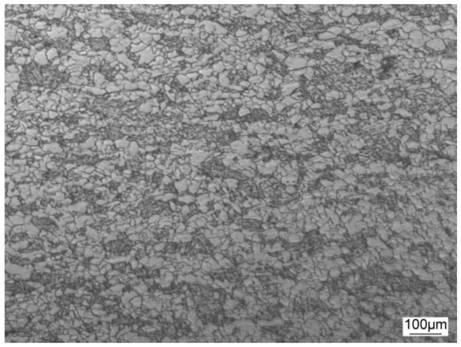

Image

Examples

Embodiment 1

[0073] A hot-rolled multiphase steel with a tensile strength of 800 MPa in this example, its main chemical composition and mass percentage are shown in Example 1 in Table 1.

[0074] The production method of a kind of tensile strength 800MPa class hot-rolled composite phase steel of the present embodiment comprises the following steps:

[0075] S1. Pretreatment of molten iron requires pre-slagging and post-slagging, and [S]≤0.0050% after desulfurization of molten iron.

[0076] S2. Converter smelting, strengthen dephosphorization, and carry out deoxidation and alloying for tapping, and at the same time strengthen the operation of blocking slag for tapping.

[0077] S3. Alloy fine-tuning station, adding aluminum particles and stirring strongly to initially reduce the top slag of the ladle.

[0078] S4, LF+RH refining, using double refining process and Ca treatment process. On the basis of controlling the chemical composition of C, Si, Mn, Nb, Ti and Mo in molten steel, the co...

Embodiment 2

[0085] A hot-rolled multiphase steel with a tensile strength of 800 MPa in this example, its main chemical composition and mass percentage are shown in Example 2 in Table 1.

[0086] The production method of a kind of tensile strength 800MPa class hot-rolled composite phase steel of the present embodiment comprises the following steps:

[0087] S1. Pretreatment of molten iron requires pre-slagging and post-slagging, and [S]≤0.0050% after desulfurization of molten iron.

[0088] S2. Converter smelting, strengthen dephosphorization, and carry out deoxidation and alloying for tapping, and at the same time strengthen the operation of blocking slag for tapping.

[0089] S3. Alloy fine-tuning station, adding aluminum particles and stirring strongly to initially reduce the top slag of the ladle.

[0090] S4, LF+RH refining, using double refining process and Ca treatment process. On the basis of controlling the chemical composition of C, Si, Mn, Nb, Ti and Mo in molten steel, the co...

Embodiment 3

[0097] A hot-rolled multiphase steel with a tensile strength of 800 MPa in this example, its main chemical composition and mass percentage are shown in Example 3 in Table 1.

[0098] The production method of a kind of tensile strength 800MPa class hot-rolled composite phase steel of the present embodiment comprises the following steps:

[0099] S1. Pretreatment of molten iron requires pre-slagging and post-slagging, and [S]≤0.0050% after desulfurization of molten iron.

[0100] S2. Converter smelting, strengthen dephosphorization, and carry out deoxidation and alloying for tapping, and at the same time strengthen the operation of blocking slag for tapping.

[0101] S3. Alloy fine-tuning station, adding aluminum particles and stirring strongly to initially reduce the top slag of the ladle.

[0102] S4, LF+RH refining, using double refining process and Ca treatment process. On the basis of controlling the chemical composition of C, Si, Mn, Nb, Ti and Mo in molten steel, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com