Soybean protein adhesive for plywood and preparation method of soybean protein adhesive

A soybean protein and adhesive technology, applied in the field of wood processing, can solve the problems of unsatisfactory stability and viscosity, insignificant synergy, poor practicability, etc., and achieve the effect of increasing added value, abundant sources and ensuring practical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

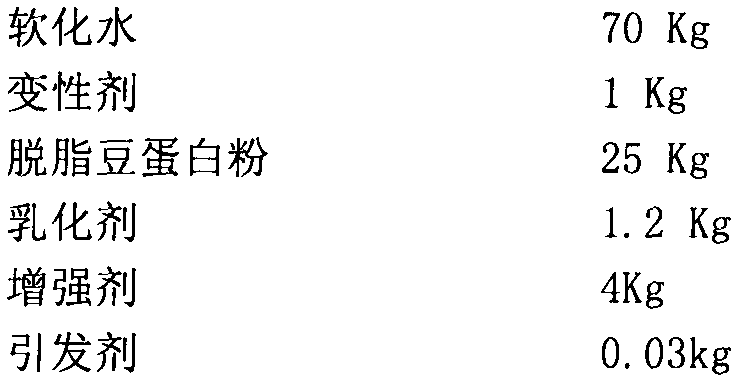

[0038] 1) Prepare materials according to the following weight ratio:

[0039]

[0040]Among them, the emulsifier is a powder prepared by the School of Resources, Environment and Materials of Guangxi University, including sodium lauryl sulfate: 1.2 parts, sodium dodecylbenzenesulfonate: 1 part, and mix them evenly; the enhancer is methyl Glyceryl acrylate, the initiator is ammonium persulfate.

[0041] 2) Add all the demineralized water, sodium carbonate and soybean protein powder into the reaction kettle equipped with a stirrer, thermometer and condensing device, and stir evenly;

[0042] 3) Heating to 45° C. and keeping the temperature for 3 hours to obtain a mixture.

[0043] 4) The mixture is cooled to room temperature to obtain a uniform soy protein mucus.

[0044] 5) Add an emulsifier to the soy protein mucus and stir evenly to make it emulsify.

[0045] 6) Continue to add the enhancer and initiator to it, and stir evenly.

[0046] 7) Heating to 45°C, keeping the t...

Embodiment 2

[0049] 1) Prepare materials according to the following weight ratio:

[0050]

[0051] Among them, the emulsifier is a powder prepared by the School of Resources, Environment and Materials of Guangxi University, including sodium lauryl sulfate: 1 part, sodium dodecylbenzenesulfonate: 1 part, and mix them evenly; the enhancer is methyl Glyceryl acrylate solution, the initiator is ammonium persulfate.

[0052] 2) Add all the demineralized water, sodium carbonate and soybean protein powder into the reaction kettle equipped with a stirrer, thermometer and condensing device, and stir evenly;

[0053] 3) Heating to 42° C. and keeping the temperature for 6 hours to obtain a mixture.

[0054] 4) The mixture is cooled to room temperature to obtain a uniform soy protein mucus.

[0055] 5) Add an emulsifier to the soy protein mucus and stir evenly to make it emulsify.

[0056] 6) Continue to add the enhancer and initiator to it, and stir evenly.

[0057] 7) Heating to 50°C, keepin...

Embodiment 3

[0060] 1) Prepare materials according to the following weight ratio:

[0061]

[0062] Among them, the emulsifier is a powder prepared by the School of Resources, Environment and Materials of Guangxi University, including sodium lauryl sulfate: 1 part, sodium dodecylbenzenesulfonate: 1.2 parts, and mix them evenly; the enhancer is methyl Glyceryl acrylate solution, the initiator is ammonium persulfate.

[0063] 2) Add all the demineralized water, sodium carbonate and soybean protein powder into the reaction kettle equipped with a stirrer, thermometer and condensing device, and stir evenly;

[0064] 3) Heating to 68° C. and keeping the temperature for 5 hours to obtain a mixture.

[0065] 4) The mixture is cooled to room temperature to obtain a uniform soy protein mucus.

[0066] 5) Add an emulsifier to the soy protein mucus and stir evenly to make it emulsify.

[0067] 6) Continue to add the enhancer and initiator to it, and stir evenly.

[0068] 7) Heating to 35°C, kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com