Preparation method of monoclinic phase vanadium dioxide nanometer powder

A technology of vanadium dioxide nanometer and vanadium dioxide, which is applied in the field of ball milling to prepare VO2 powder, which can solve the problems of affecting product performance, not being easy to powder, increasing production costs, etc., achieving high production efficiency, short time, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of monoclinic phase vanadium dioxide nanopowder, comprising the following steps:

[0038] (1) Hydrothermal preparation:

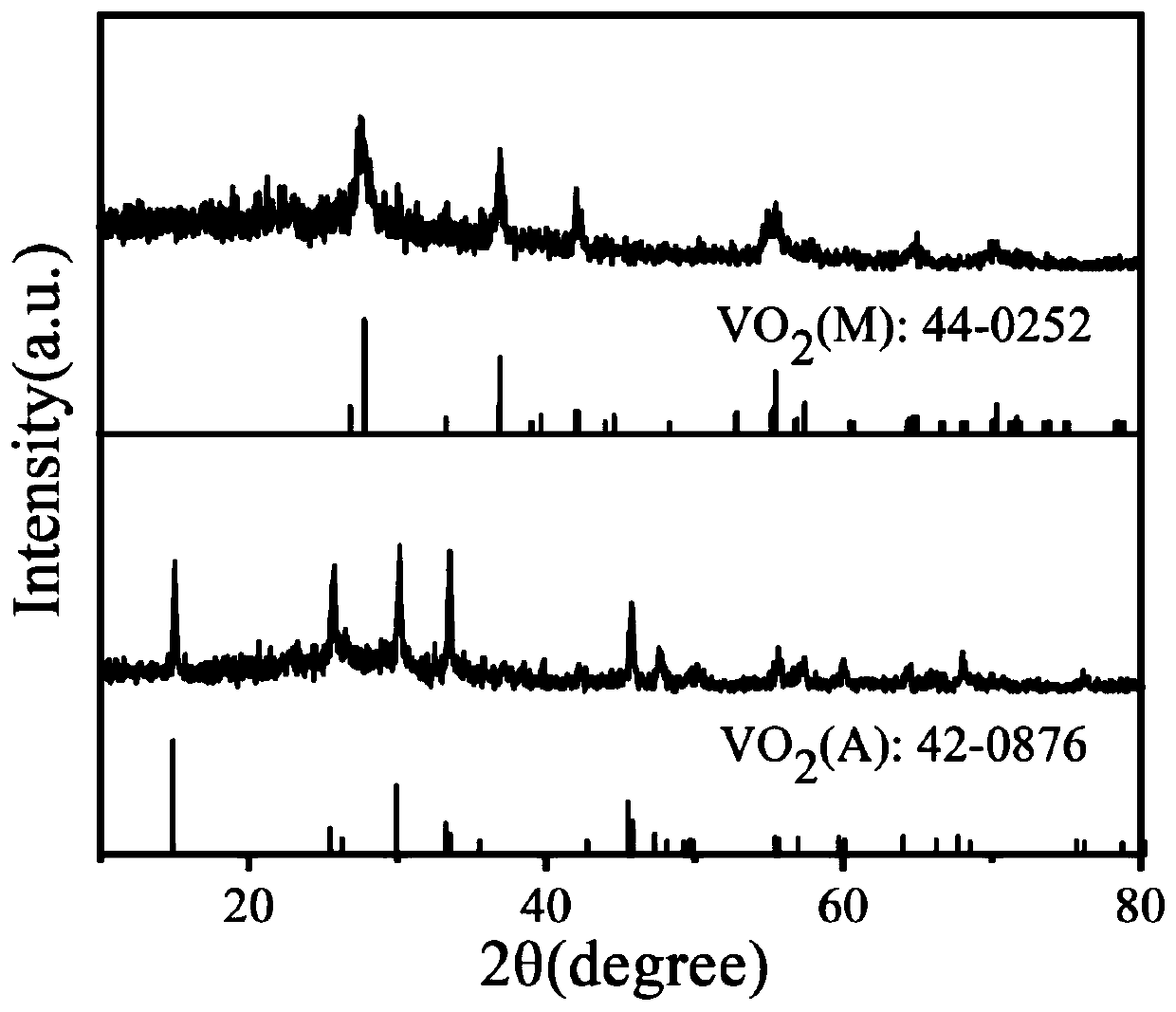

[0039] will V 2 o 5(1.001g) was added to 20mL of deionized water, then 1.5ml of concentrated sulfuric acid was added, stirred with a magnetic stirrer at 60-70°C for 10min, and then 0.520g of N 2 h 4 ·HO 2 Adjust the pH to 3-4 using sodium hydroxide and transfer to a Teflon-lined stainless steel autoclave. The autoclave was sealed and reacted at 230°C for 24 hours. Subsequently, the autoclave was slowly cooled to room temperature to obtain the product, which was washed twice with deionized water and once with ethanol to remove the residue, and dried at 80°C for 10 hours to obtain a powder Body, carry out X-ray diffraction (XRD) test, and with VO 2 (A) Standard card comparison, such as figure 1 As shown, the obtained powder is VO 2 (A) Powder.

[0040] (2) Ball milling treatment:

[0041] 1) 3.000g VO obtained by heating ...

Embodiment 2

[0046] A preparation method of monoclinic phase vanadium dioxide nanopowder, comprising the following steps:

[0047] (1) Hydrothermal preparation:

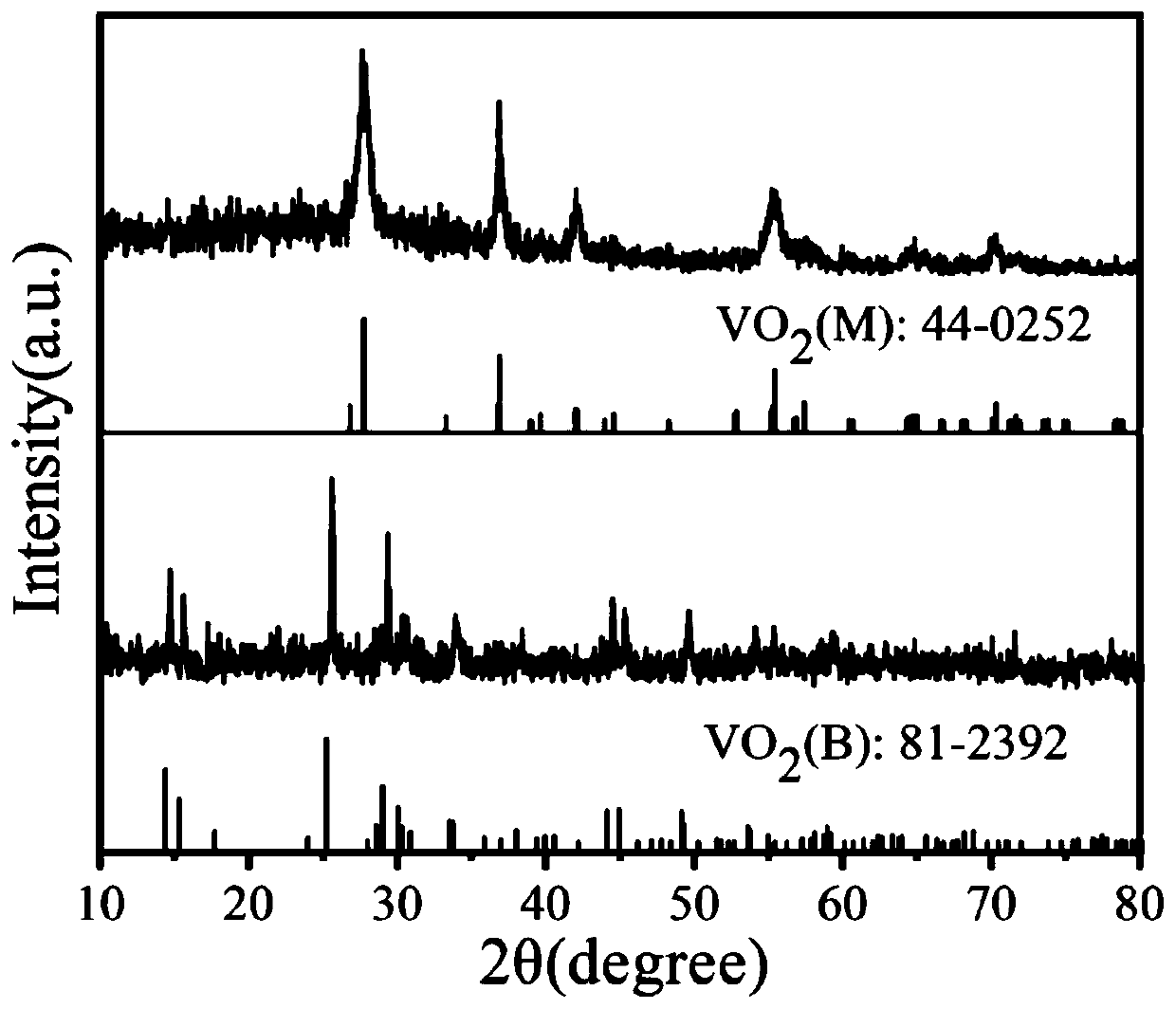

[0048] will V 2 o 5 Add 0.600g and 0.790g of oxalic acid into 40mL of deionized water. Stir for 1 h with a magnetic stirrer to obtain a blue transparent liquid, which is transferred to a polytetrafluoroethylene-lined stainless steel autoclave. The autoclave was sealed and reacted at 210° C. for 24 h, and then the autoclave was slowly cooled to room temperature. The product was obtained, washed three times by centrifugation with absolute ethanol, and the residue was removed, and vacuum-dried at 55°C for 12h to obtain a powder, which was tested by X-ray diffraction (XRD), and compared with VO 2 (B) Standard card comparison, such as figure 2 As shown, the obtained powder is VO 2 (B) Powder.

[0049] (2) Ball milling treatment:

[0050] 1) 1.123g VO obtained by heating step (1) multiple times 2 (B) The powder was mixed wit...

Embodiment 3

[0055] A preparation method of monoclinic phase vanadium dioxide nanopowder, comprising the following steps:

[0056] (1) Hydrothermal preparation:

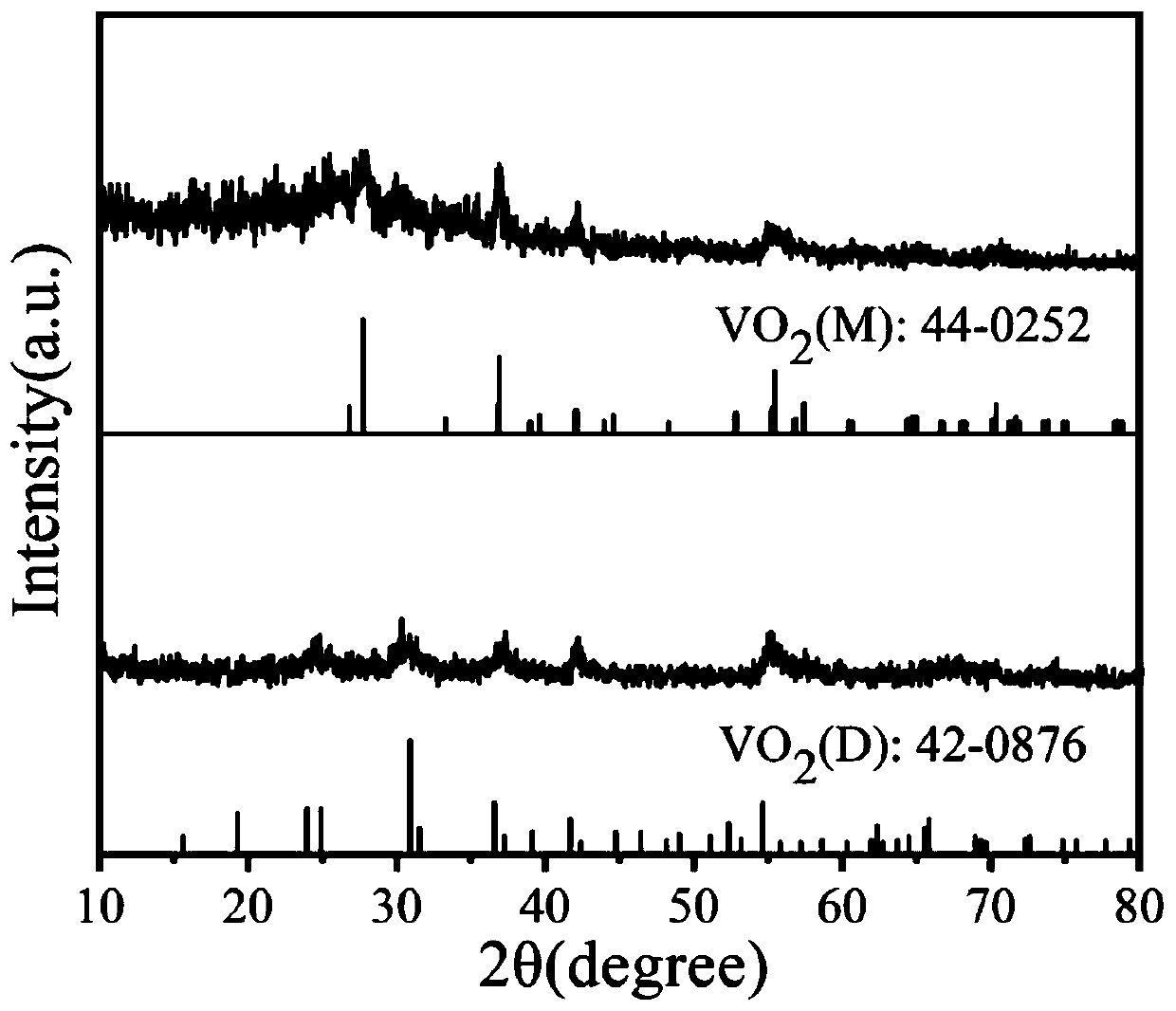

[0057] will V 2 o 5 (0.8014g) was added to 20mL deionized water, stirred with a magnetic stirrer at 60-70°C for 10min, then added 0.5200gN 2 h 4 ·HO 2 Adjust the pH to 7-8 using sodium hydroxide and transfer to a Teflon-lined stainless steel autoclave. The autoclave was sealed and reacted at 260° C. for 24 h, and then the autoclave was slowly cooled to room temperature. Obtain the product, wash twice with deionized water, wash once with ethanol, remove the residue, dry at 80°C for 10h, obtain powder, carry out X-ray diffraction (XRD) test, and compare with VO 2 (D) Standard card comparison, such as image 3 As shown, the obtained powder is VO 2 (D) Powder.

[0058] (2) Ball milling treatment:

[0059] 1) 2.023g VO obtained by heating step (1) multiple times 2 (D) Powder, mixed with 2.345 g of butyric acid.

[0060] 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com