Polishing device for engine piston insert ring machining

A polishing device and engine technology, applied in grinding/polishing safety devices, metal processing equipment, machine tools with surface polishing, etc., can solve problems such as troublesome grinding of piston inserts, avoid dust flying, ensure cleanliness, and facilitate use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

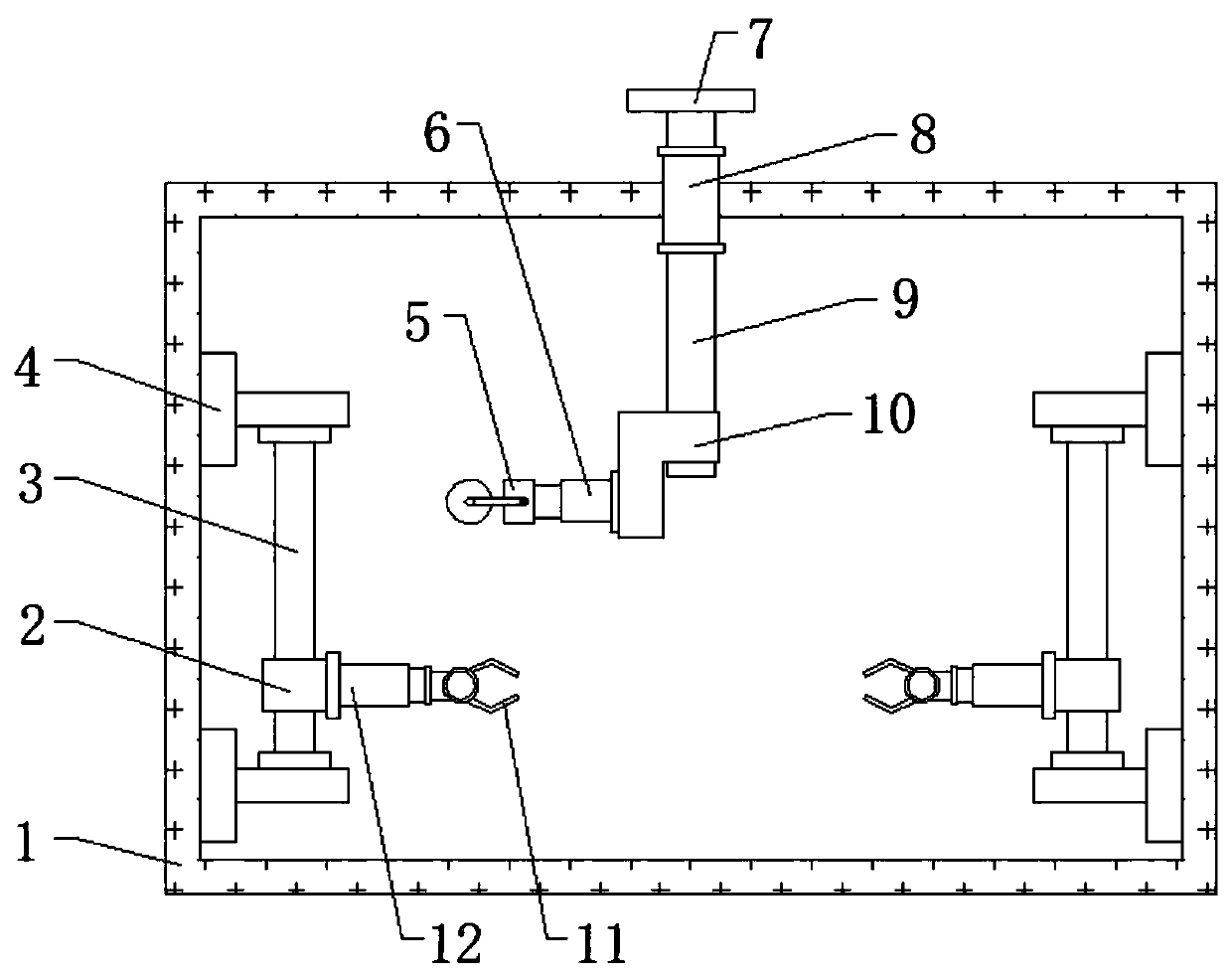

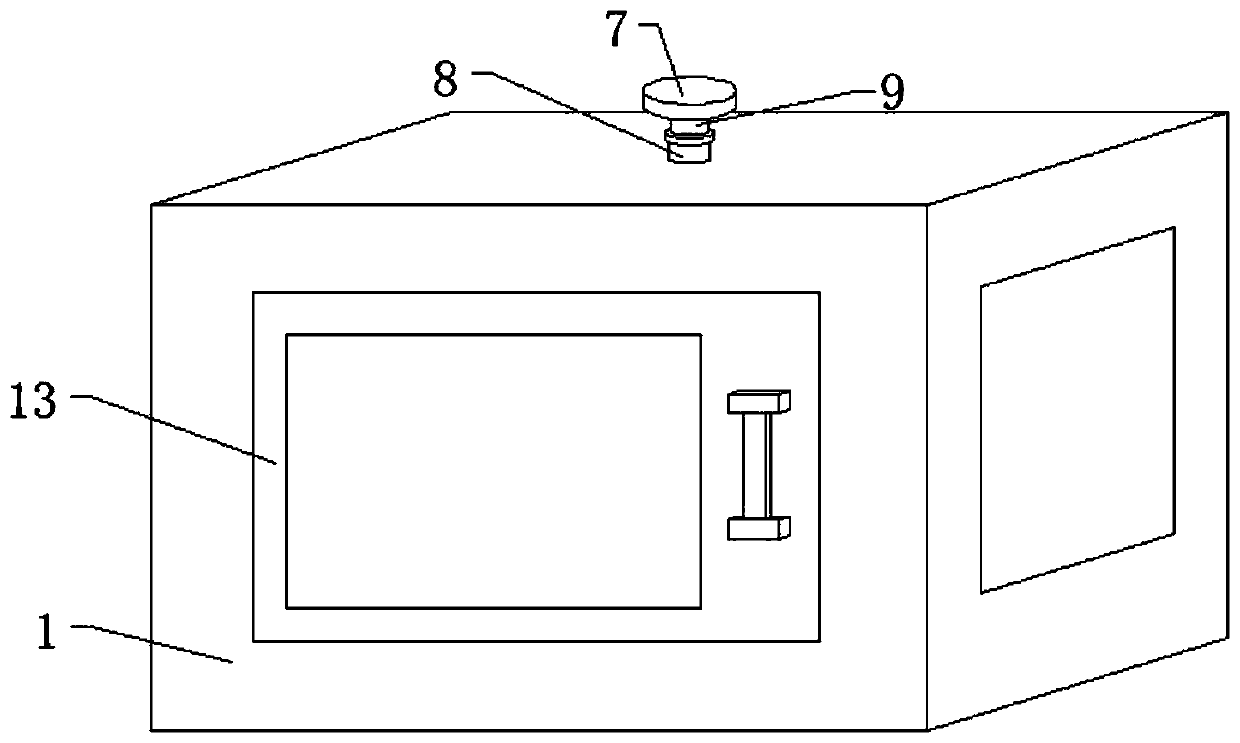

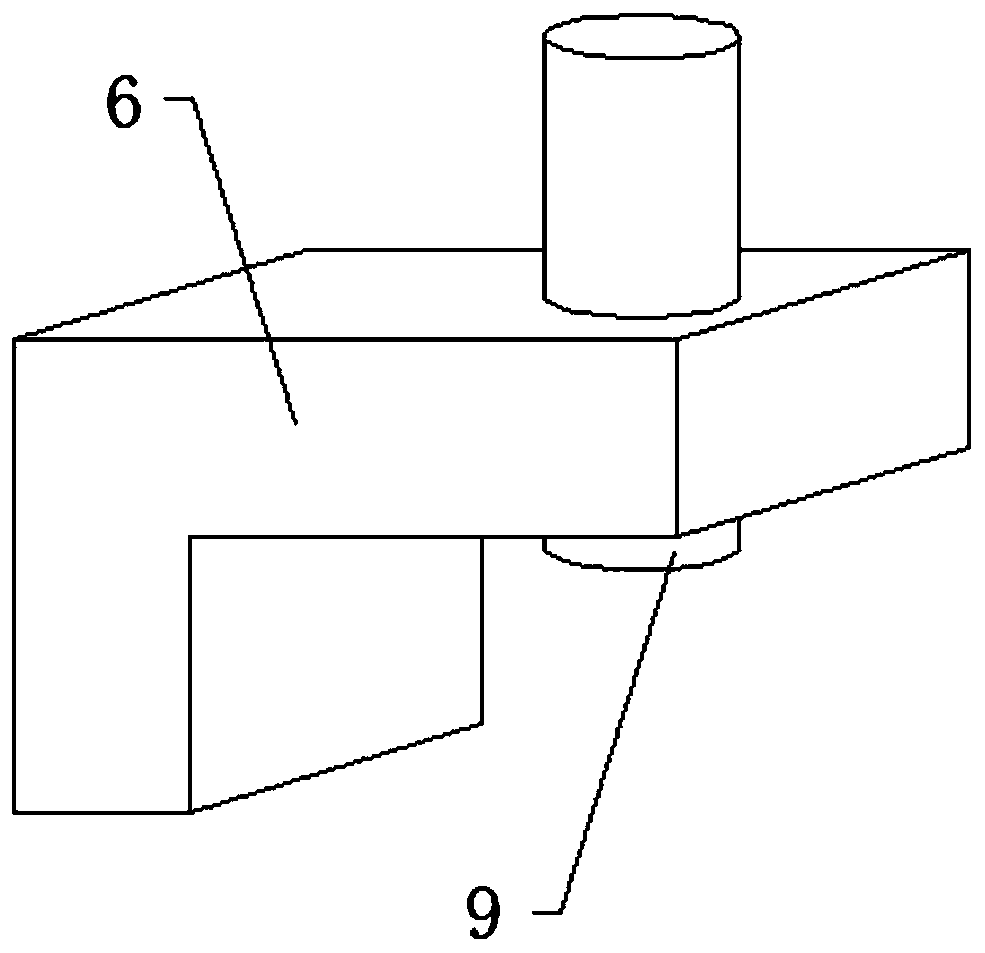

[0025] Reference Figure 1-3 , A polishing device for processing engine piston inserts, comprising a box body 1 and two clamping mechanisms. A mounting hole is opened in the middle of the outer wall of the top of the box body 1, and a sleeve 8 is inserted on the inner circumferential wall of the mounting hole. A connecting rod 9 is inserted into the circumferential inner wall of the sleeve 8, an L-shaped plate 10 is sleeved on the circumferential outer wall of the connecting rod 9, and a second electric telescopic rod 6 is fixed on one outer wall of the L-shaped plate 10 by bolts, One end of the extension rod of the second electric telescopic rod 6 is fixed with a polishing machine 5 by bolts, and a polishing sheet is hinged on one side of the outer wall of the polishing machine 5, and the clamping mechanisms are respectively located on both sides of the inside of the box body 1.

[0026] In the present invention, the top end of the connecting rod 9 is welded with a handle 7, and...

Embodiment 2

[0029] Reference Figure 4 , A polishing device for machining engine piston inserts. Compared with the first embodiment, this embodiment further includes a vacuum cleaner 14 which is fixed on one side of the inner wall of the top of the box 1 by bolts.

[0030] Working principle: When in use, during the polishing process, the vacuum cleaner 14 is started to vacuum, to avoid excessive dust inside the cabinet 1, and to ensure a clean working environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com