High-strength plastic honeycomb core material with inner support and preparation process of high-strength plastic honeycomb core material

A technology of plastic honeycomb and preparation process, applied in other household appliances, sheets/boards, building elements, etc., can solve the problem of reducing surface material and structural design flexibility, reducing height or aperture, weak lateral compression performance, etc. problems, to achieve the effect of being conducive to large-scale promotion and application, increasing stability, and reducing classification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

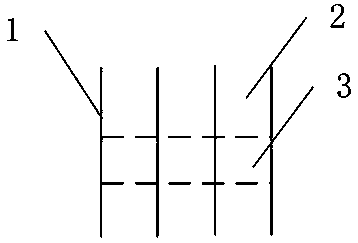

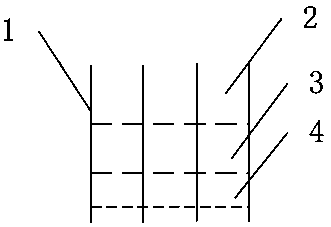

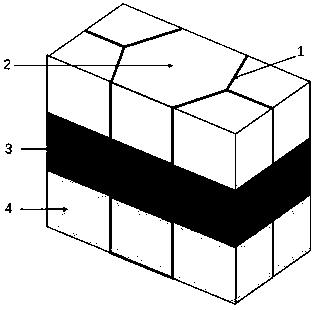

[0041] The high-strength plastic honeycomb core material with internal support includes a honeycomb wall 1 and a honeycomb cell 2 surrounded by the honeycomb wall 1, and a support mechanism 3 inside each honeycomb cell 2, the honeycomb cell 2 is hexagonal, and the support Mechanism 3 adapts to the shape of the honeycomb cell, which is also hexagonal. The supporting mechanism 3 is a three-dimensional mechanism, which fills the honeycomb cells 2 and supports the honeycomb wall 1, so that the honeycomb wall 1 is more stable under force. The upper top surface and the lower bottom surface of the support mechanism 3 are both planar structures or close to planar structures; the support mechanism 3 is actually composed of a plurality of support units, and each support unit is relatively independent and is located in each honeycomb cell 2 Inside;

[0042] The support mechanism 3 is mainly made of polyethylene, polypropylene, polyvinyl chloride, polystyrene or any one of modified therm...

Embodiment 2

[0052] The honeycomb core material is obtained by traditional preparation process;

[0053] Or use the manufacturing process in ZL201610492628.7 to prepare thermoplastic flat panels by extruding thermoplastics, and go through processes such as core strip coating, lamination, pressing, cutting, stretching, shaping, dipping, curing, and slice cutting. The plastic honeycomb core material is prepared;

[0054] The present invention is in actual preparation process, and its technology is as follows:

[0055] On the basis of the honeycomb core material prepared by the above traditional process, the following raw materials are filled into the honeycomb cells:

[0056] S1: Polyvinyl alcohol powder with a degree of polymerization of 1500 and a degree of alcoholysis of about 90% is used as the main raw material, and the components of the polyvinyl alcohol powder are: 60 parts of polyvinyl alcohol, 1 part of antioxidant, 4 parts of heat stabilizer, 1.5 parts of fluidity modifier, 0.3 p...

Embodiment 4~ Embodiment 8

[0063] The difference from Example 1 is that the parts by weight of each raw material in S1 are different, and each raw material is shown in Table 1 and 2 below:

[0064] The consumption of each raw material in table 1 embodiment 4~8

[0065]

[0066] In embodiment 5: in addition, in S2, adopt non-foaming type material: polyethylene;

[0067] In embodiment 6: in S2, adopt non-foaming type material: polyvinyl chloride;

[0068] In Example 7: in S2, non-foaming material is used: polystyrene;

[0069] In Example 8: In S2, non-foaming material: polypropylene is used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com