Polymer with emulsifying water demulsifying and coalescence functions, and preparation method and applications thereof

A technology for emulsification of water and polymers, applied in the field of polymer materials and filter materials, can solve the problems of demulsification and dehydration behavior, long-term effect of materials, etc., to achieve a wide range of applications, efficient demulsification and coalescence, strong The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 A polymer with emulsified water demulsification and coalescence functions

[0054] The raw material composition of the polymer with emulsified water demulsification and coalescence functions described in this example is shown in Table 1, and is prepared by the following steps:

[0055] I. prepare raw materials according to the proportioning shown in table 1;

[0056] II. Combine all monomers (polyethylene glycol (400) monoester methacrylate (the average degree of polymerization n is about 9), itaconic acid, hydroxyethyl methacrylate, glycidyl methacrylate, butyl acrylate ester, isooctyl acrylate, methyl methacrylate) and chain transfer agent (dodecanethiol), stir well, add 1 / 2 of the initiator (1.1 parts of azobisisobutyronitrile), stir well, to obtain a mixed solution;

[0057] III. Add organic solvent (dioxane and xylene) and remaining initiator (1.1 parts of azobisisobutyronitrile) in the reactor that is provided with stirring device, condensing device, t...

Embodiment 2

[0059] Example 2 A polymer with emulsified water demulsification and coalescence functions

[0060] The raw material composition of the polymer with emulsified water demulsification and coalescence functions described in this example is shown in Table 1, and is prepared by the following steps:

[0061] I. prepare raw materials according to the proportioning shown in table 1;

[0062] II. All monomers (polypropylene glycol (400) methacrylate monoester (the average degree of polymerization n is about 7), polyethylene glycol (200) monoacrylate (the average degree of polymerization n is about 4), acrylic acid Hydroxyethyl ester, butyl acrylate, ethyl methacrylate) and chain transfer agent (α-methylstyrene linear dimer), stir evenly, add two-thirds of the initiator (azobisisobutyronitrile 1.73 parts), stir well, obtain mixed solution;

[0063] III. Add organic solvent (isopropanol and butyl acetate) and remaining initiator (0.87 parts of azobisisobutyronitrile) in the reactor tha...

Embodiment 3

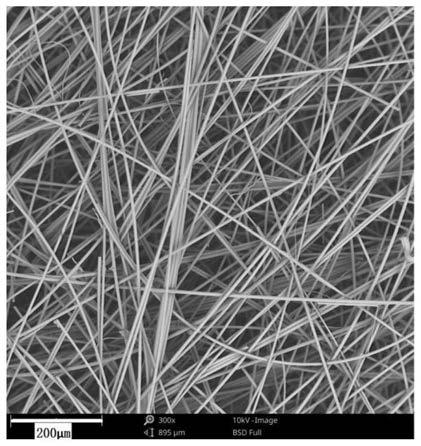

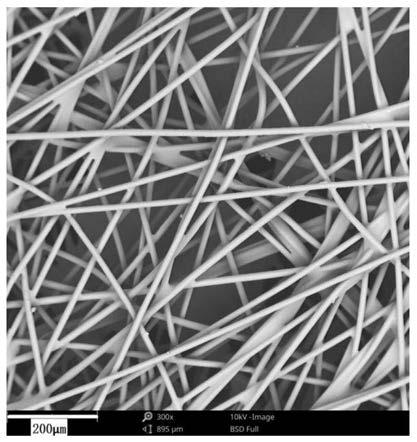

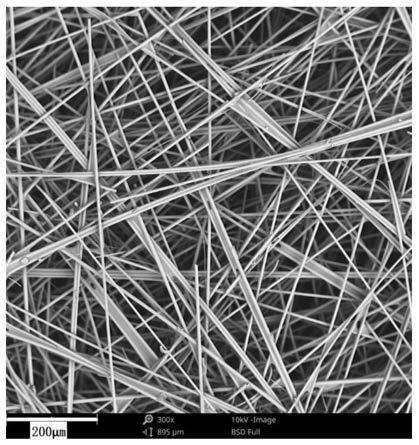

[0073] Embodiment 3 has the filter material of emulsified water demulsification, coalescing function

[0074] The polymer with emulsified water demulsification and coalescing functions prepared in the above-mentioned examples 1 and 2 is respectively mixed with curing agent amino resin (American Hytex Corporation, CYTEC327), and the polymer with emulsified water demulsifying and coalescing functions is accounted for according to the quality of the curing agent. After compounding 10wt% of the polymer, mix it evenly, dilute it with an organic solvent (same as the solvent used to prepare the resin) until the concentration of the solute (polymer and amino resin curing agent) is 3.0wt%, and filter the base paper with glass fiber Immerse in the above-mentioned diluted polymer mixed solution of Example 1, impregnate the non-woven filter material into the above-mentioned diluted polymer mixed solution of Example 2, take it out after soaking for three minutes, and use a drying device at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com