Injection molding device for thermoplastic polyurethanes (TPU) barrel materials

A thermoplastic polyurethane and elastic technology, which is applied in the field of thermoplastic polyurethane elastomer barrel material injection molding device, can solve the problems that barrel materials are prone to flow lines, bubbles, and cannot be formed by pouring, so as to achieve no flow marks, improve accuracy and life, and eliminate air effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The purpose of the present invention can be achieved through the following technical solutions:

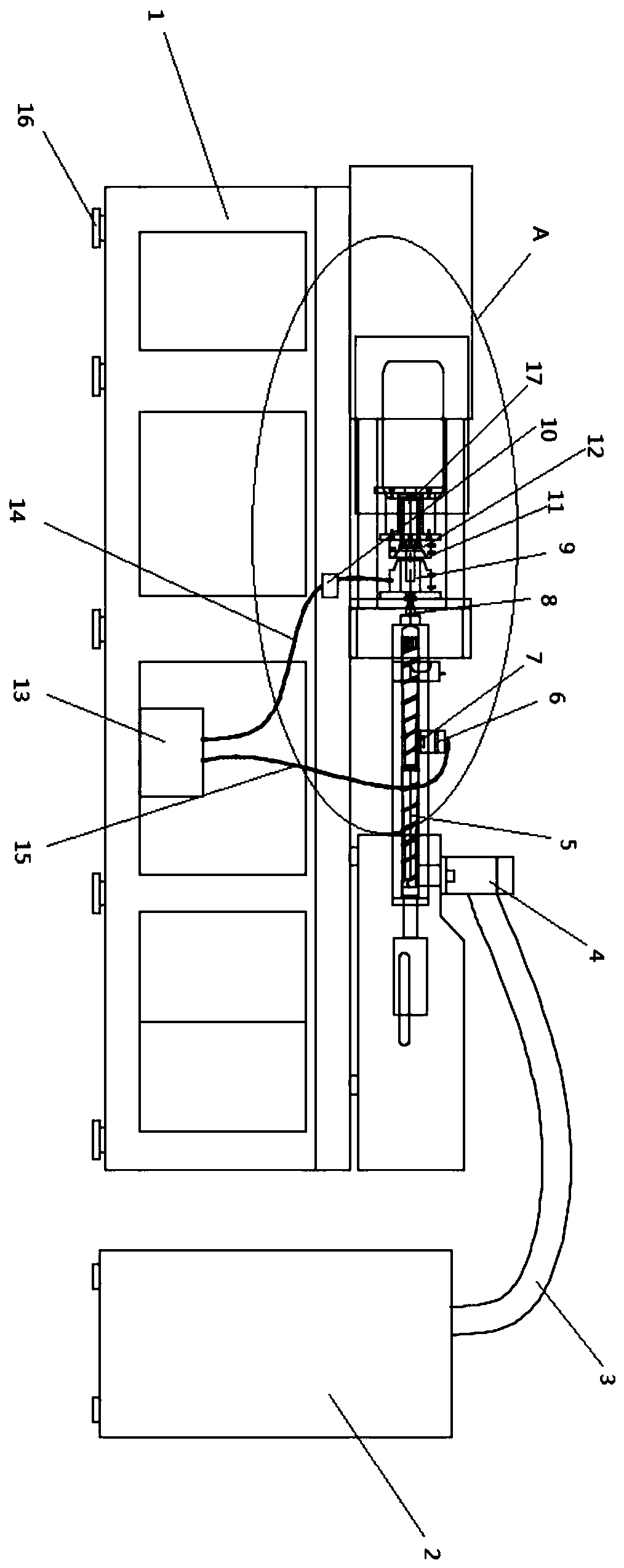

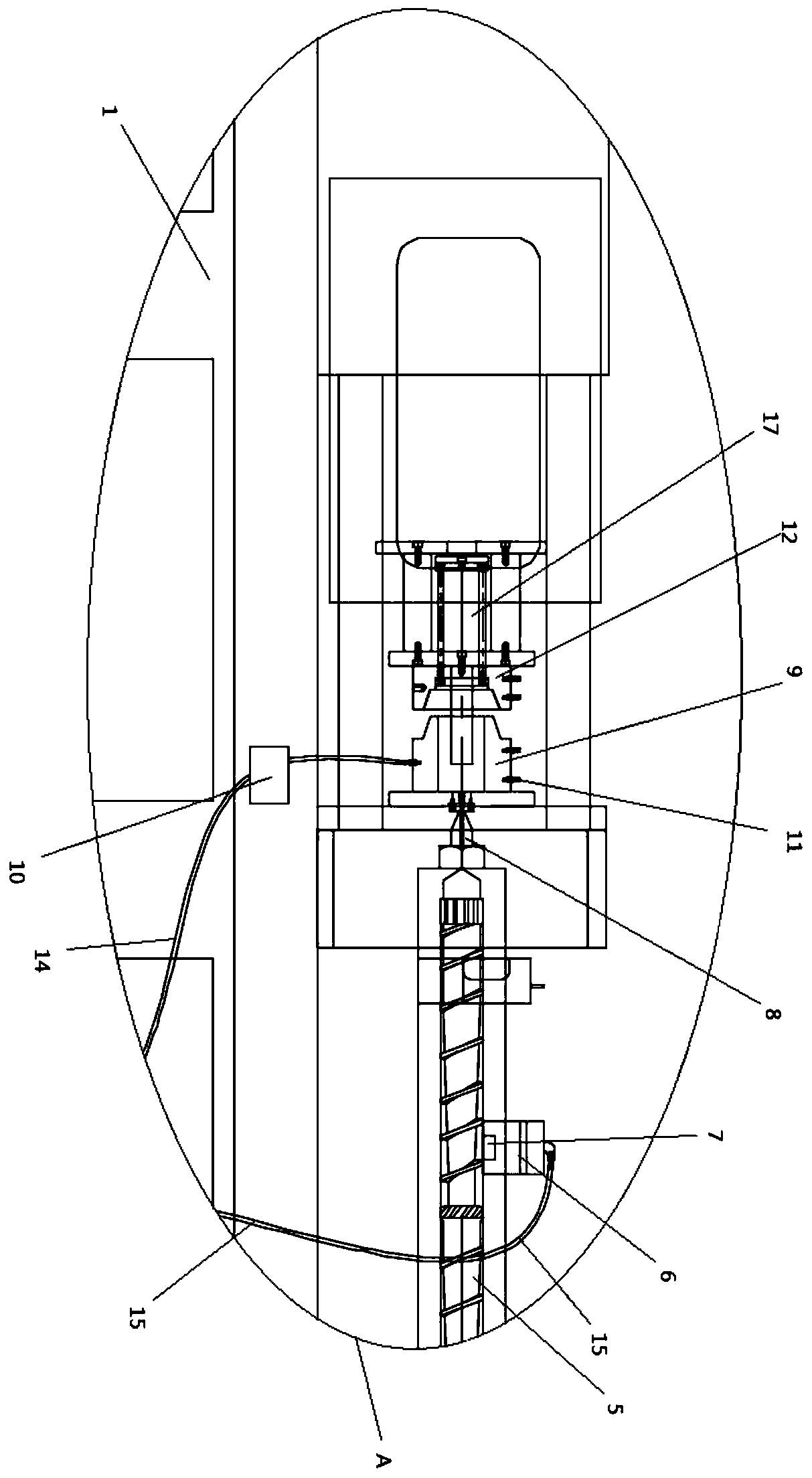

[0027] A thermoplastic polyurethane elastomer bucket material injection molding device, see Figure 1-2 , including base 1, dehumidification dryer 2, drying pipe 3, quantitative drying funnel 4, multi-edge variable pressure screw 5, heat preservation and exhaust device 6, exhaust port 7, nozzle 8, nozzle 9, solenoid valve 10, cooling Mouth 11, mold 12, vacuum pump 13, nozzle vacuum tube 14, heat preservation and exhaust vacuum tube 15, shockproof pad 16, rear ejector rod 17;

[0028] The base 1 is provided with a multi-edge variable pressure screw 5, the right end of the multi-edge variable pressure screw 5 is provided with a quantitative drying funnel 4, and the multi-edge variable pressure screw 5 is provided with an exhaust device 6; the left end of the multi-edge variable pressure screw 5 is provided with There is a nozzle 8, and the nozzle 8 cooperates with the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com