Swinging wing engine

An engine, wing type technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., to achieve the effects of simple and compact structure, short circulation paths, and low air leakage rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below knot and accompanying drawing and embodiment the present invention will be further described:

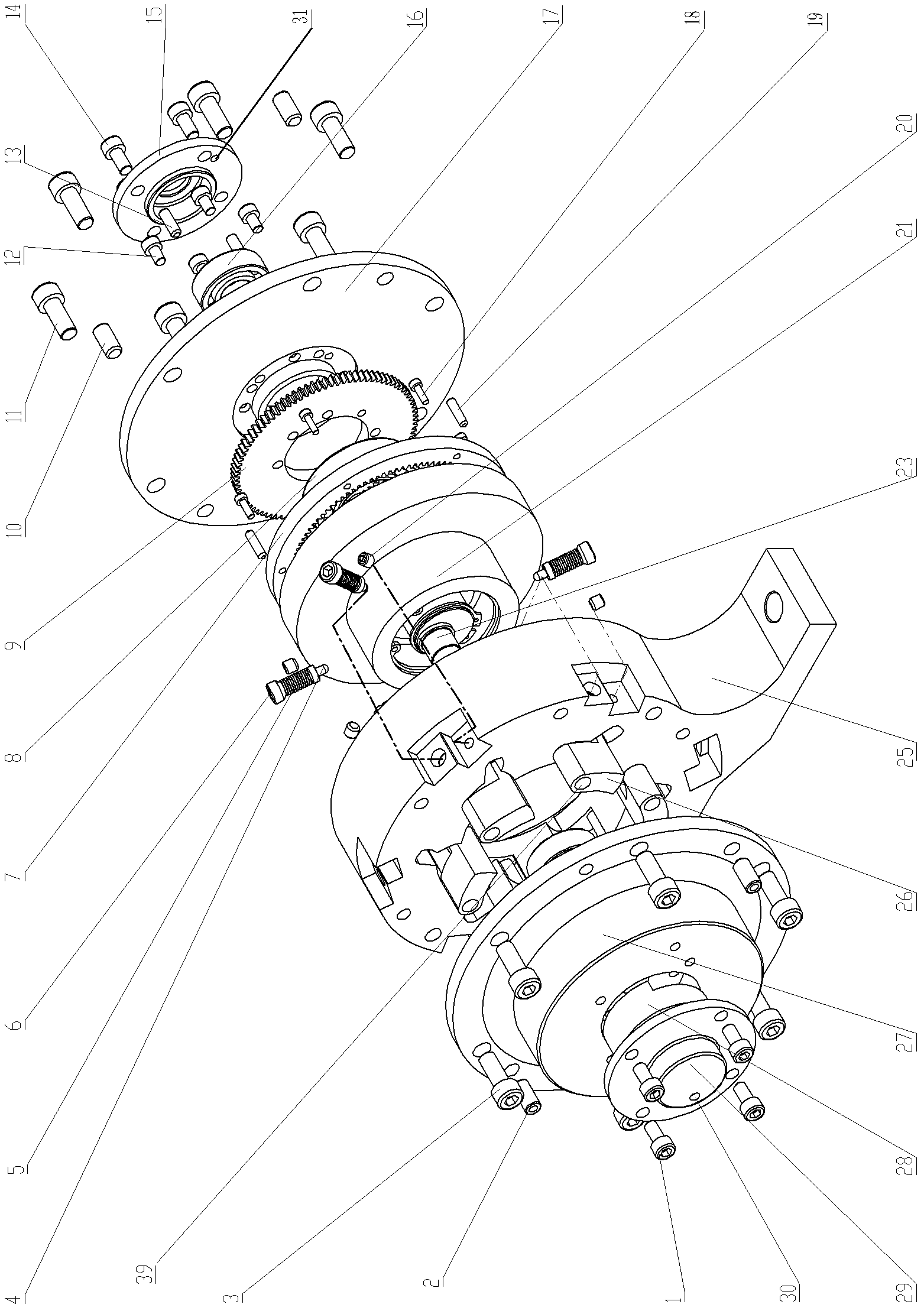

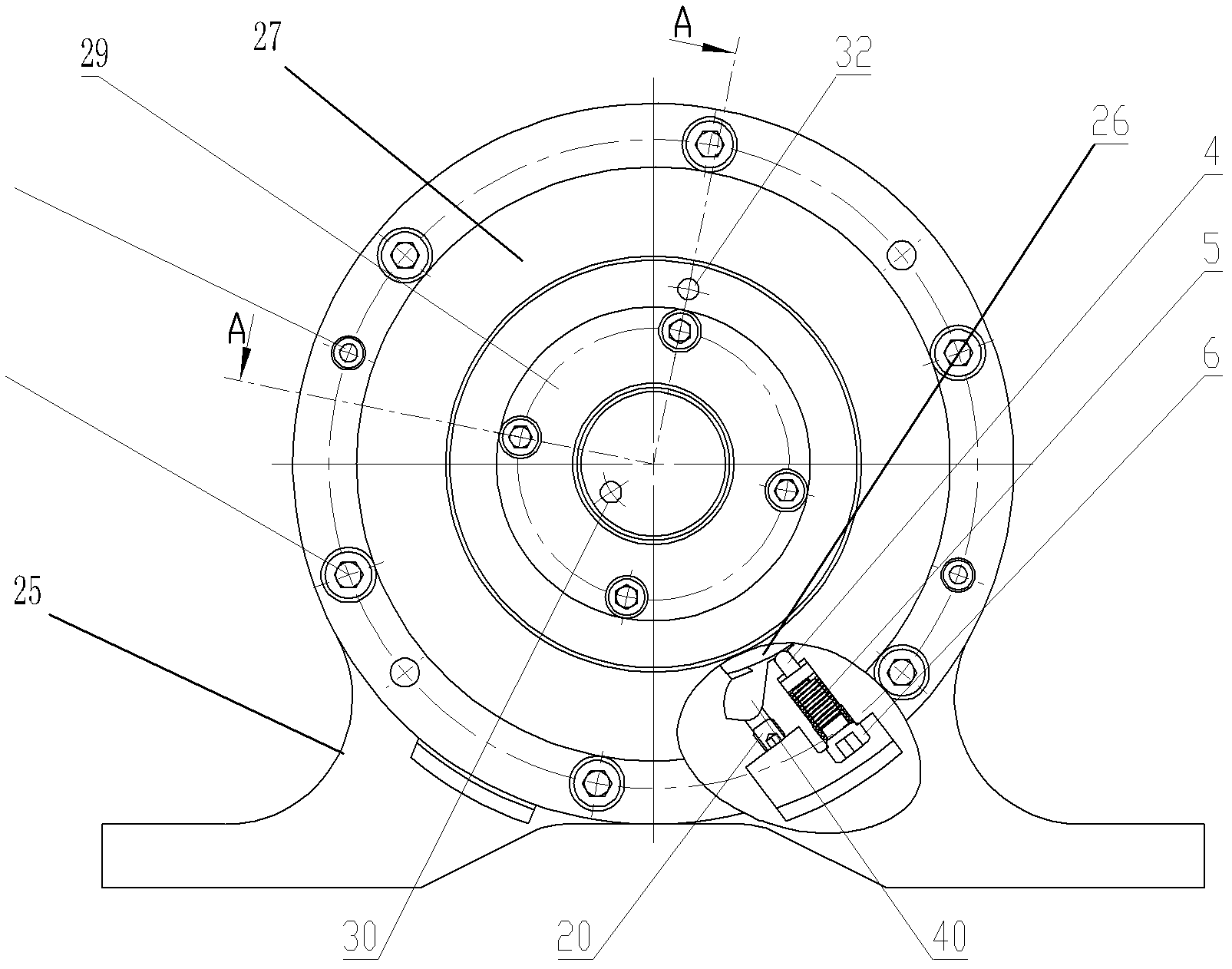

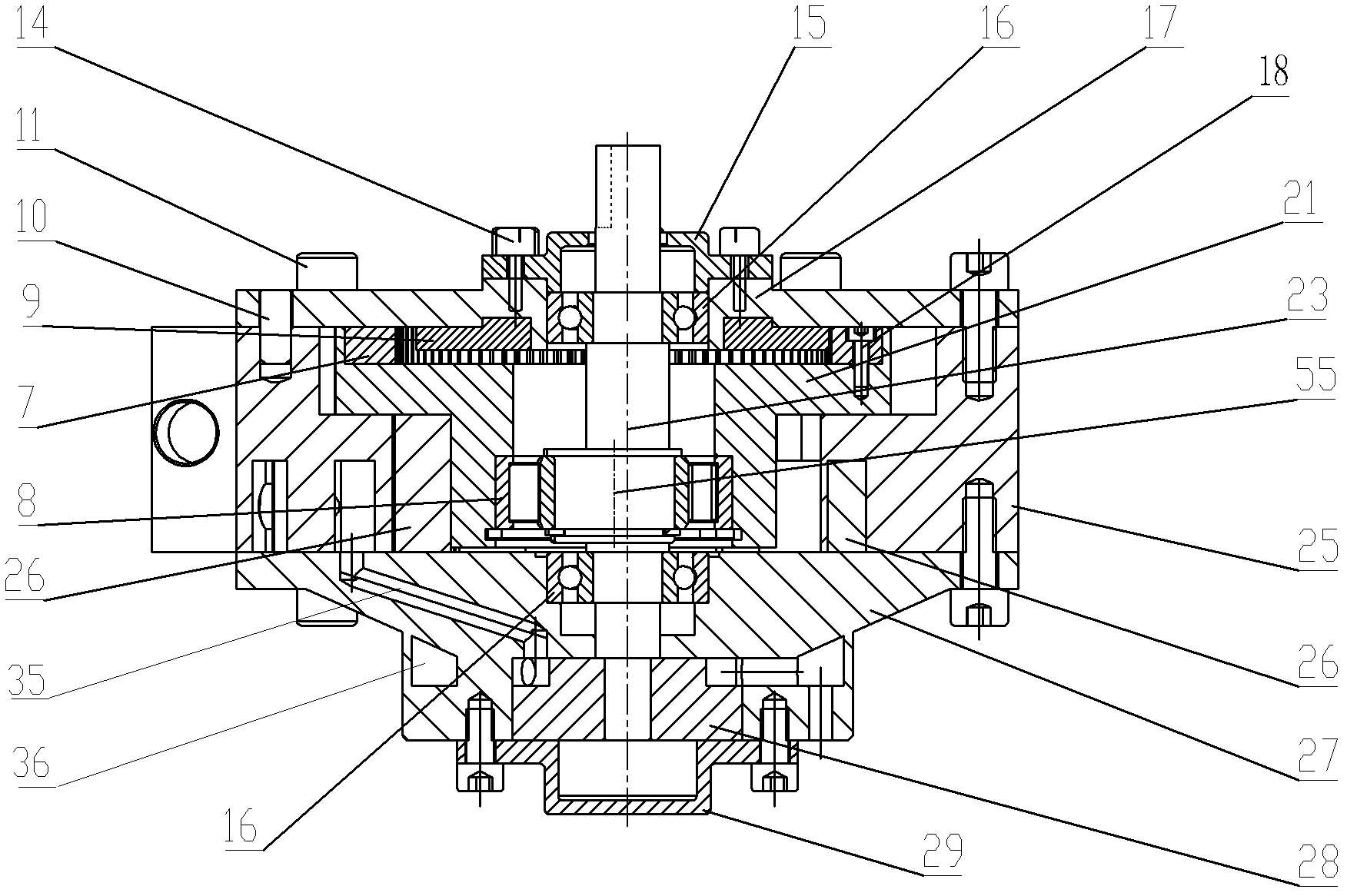

[0052] Such as Figure 1~4 As shown, the embodiment of the present invention provides a swing-wing engine, which includes a casing 25, a rotor 21 disposed in the casing, and an output shaft 23 installed coaxially with the casing. The middle part of this output shaft 23 is provided with an eccentric shaft section 55 (combined with Figure 9a ), and the inner circle 46 of the rotor 21 is connected with the eccentric shaft section 55 of the output shaft 23 through a rotor bearing 8, and the upward end surface of the rotor 21 is embedded with an internal meshing phase gear 7, and the two are connected by screws 18 and positioning pins 19 fixed (combined with Figure 8a , Figure 8b ). The upward facing end surface of the housing 25 is connected to the upper end cover 17 through positioning pins 10 and screws 11, while the inner surface of the upper end cover is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com