Composite titanium removing agent and smelting method for reducing titanium content of molten steel

A smelting method and technology of titanium content, applied in the smelting field of composite detitanium removal agent and reducing the titanium content of molten steel, can solve the problems of unqualified products, reduce the titanium content of molten steel, etc., achieve less increase in cost, lower melting point of slag, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

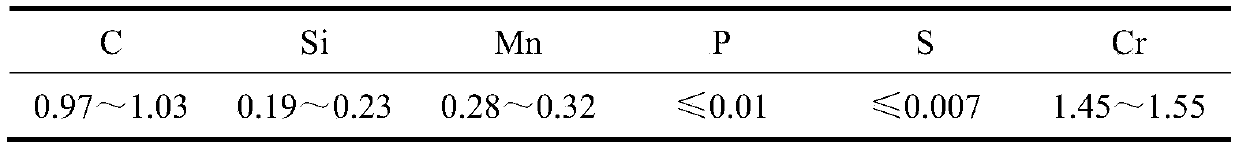

[0027] In this embodiment, the smelting method for reducing the titanium content of molten steel according to the present invention is applied to the smelting of bearing steel. The composition of the bearing steel is shown in Table 1:

[0028] Table 1 Bearing steel grade composition requirements (mass percentage %)

[0029]

[0030] Although the composition of finished steel does not have specific requirements for titanium content, because titanium has a greater influence on the fatigue life of bearing steel, it must be strictly controlled.

[0031] The smelting process of bearing steel is: hot metal pretreatment → converter steelmaking → LF refining → RH vacuum treatment → continuous casting. The specific steps are as follows:

[0032] (1) Pre-treat 180t hot metal. In addition to the normal desulfurization treatment, add 360kg of composite detitanium agent to the hot metal. The particle size of the composite detitanium agent is D50=25mm. The composite detitanium agent contains the fol...

Embodiment 2

[0045] In this embodiment, the smelting method for reducing the titanium content of molten steel according to the present invention is applied to the smelting of non-oriented silicon steel. The composition of the steel grade is shown in Table 5:

[0046] Table 5 Composition requirements of non-oriented silicon steel grades (% by mass)

[0047]

[0048] The smelting process of non-oriented silicon steel is: hot metal pretreatment → converter smelting → LF furnace refining → RH furnace refining → CC (casting), the specific steps are as follows:

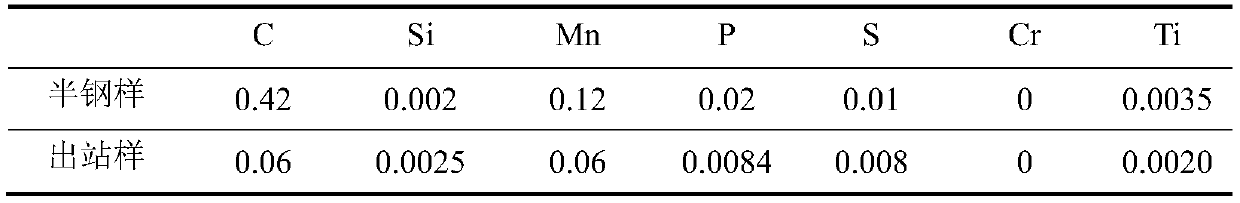

[0049] (1) Pre-treat 180t molten iron. In addition to the normal desulfurization treatment, add 400kg of composite detitanium agent to the molten iron. The particle size of the composite detitanium agent is D50=30mm. The composite detitanium agent contains the following components: Fe 2 O 3 160kg, CeO 2 160kg, CaF 2 80kg, the treatment time is 13min, after the treatment, the slag is removed. The composition changes of the molten iron before a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com