Layered zirconia porcelain block technology with even contraction of all layers

A technology of zirconia and zirconia powder, applied in the field of oral materials, can solve the problems of scrapped zirconia porcelain blocks, deformation of dental bridges, different sintering shrinkage rates, etc., to alleviate the bottleneck of resource shortage, reduce the requirements of operators, improve effect on quality of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

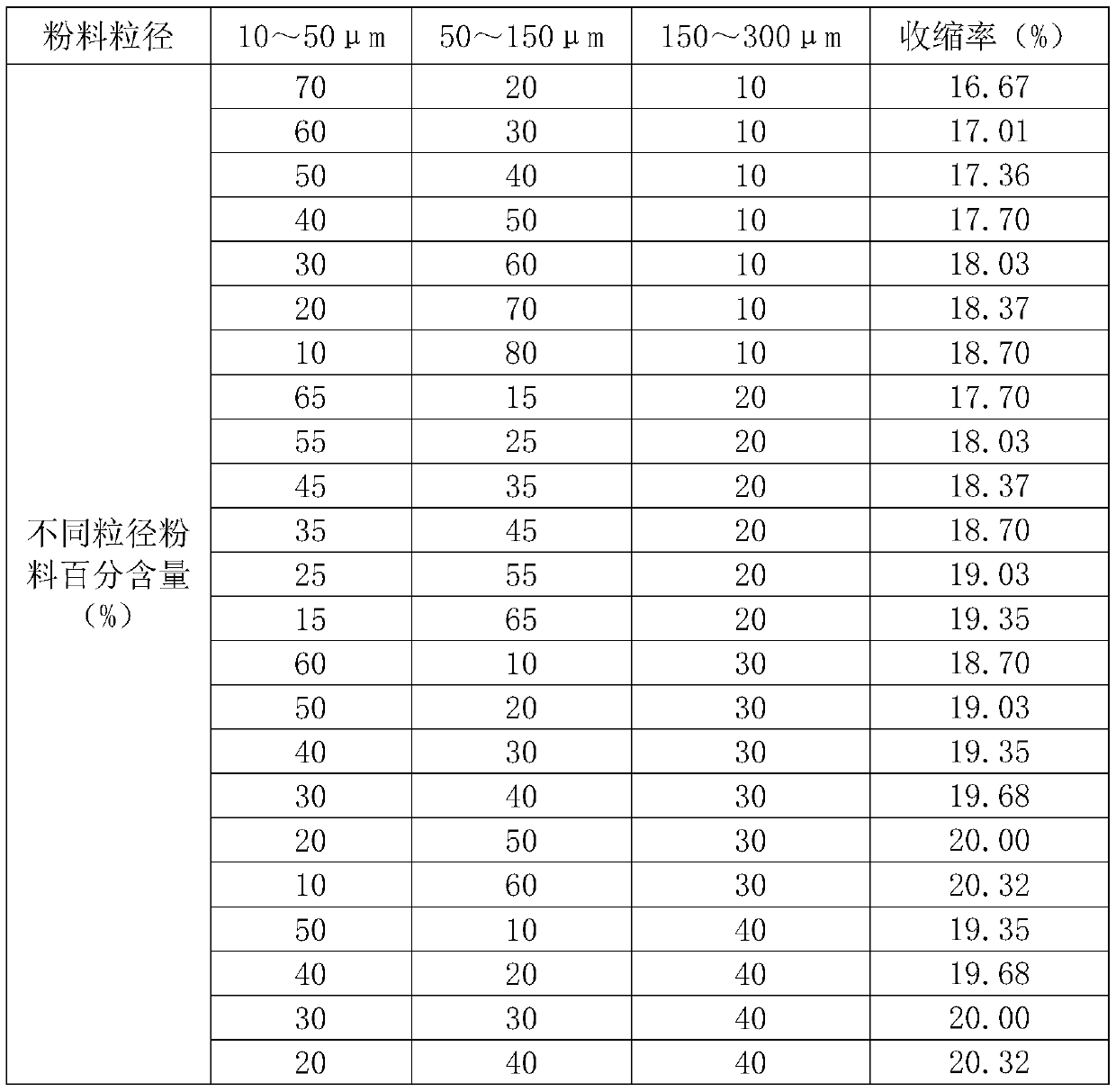

Method used

Image

Examples

Embodiment

[0035]1. Set the zirconia powder formula of the lightest color layer and the darkest color layer. In this example, the zirconia powder used was purchased from Shanghai Linghao Metal Material Co., Ltd., and the product number is ZR-2. The formula of the lightest colored layer is (by mass): 94.7% of zirconia powder, 5% of yttrium oxide powder, and 0.3% of colorant. The formula of the darkest layer is (by mass): 96.5% of zirconia powder, 3% of yttrium oxide powder, and 0.5% of coloring matter. The colorant may be one or more of erbium chloride, ferric chloride, neodymium nitrate, manganese nitrate, ammonium metavanadate, cerium nitrate, praseodymium nitrate, cobalt nitrate and nickel nitrate. For the convenience of operation, all the examples of the present invention use the colored matter obtained by mixing erbium chloride, ferric chloride, and manganese nitrate in a mass ratio of 6:1:2, and the color is tetracycline gray.

[0036] 2. Carry out the production of the whole zirc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com