Method for treating heavy metal copper ions in industrial sewage by combined adsorbent

A technology of industrial sewage and copper ions, applied in water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of limited adsorption capacity, weak force of metal ions and adsorbents, etc., to achieve Good adsorption and removal functions, important social and economic benefits, and the effect of overcoming high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

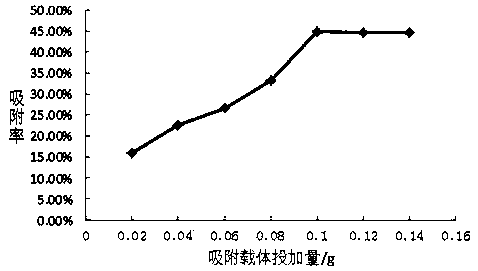

Image

Examples

Embodiment 1

[0028] A method for treating heavy metal copper ions with a combined adsorbent in industrial sewage is characterized in that it comprises the following steps:

[0029] (1) Preparation of adsorption carrier: Dissolve tofu chai pectin in deionized water, adjust the pH to 8 with sodium hydroxide solution, stir and hydrolyze for 10 minutes at room temperature;

[0030] (2) Magnetic separator Fe 3 o 4 Preparation: Take FeCl 3 •6H 2 O was dissolved in deionized water, and then transferred to a three-necked flask, and N was added dropwise under ultrasonic and stirring conditions. 2 H4•H 2 O, ultrasonic stirring continued after the dropwise addition; FeSO was added dropwise under ultrasonic 4 •7H 2 O solution, ultrasonically stirred at room temperature for 10 min; then NH was added dropwise to the solution 3 •H 2 O, adjust pH=9 with deionized water, then stir at room temperature for 30 min; after stirring, then carry out magnetic separation, wash the reaction product with deio...

Embodiment 2

[0033] A method for treating heavy metal copper ions with a combined adsorbent in industrial sewage is characterized in that it comprises the following steps:

[0034] (1) Preparation of adsorption carrier: Dissolve tofu chai pectin in deionized water, adjust the pH to 8 with sodium hydroxide solution, stir and hydrolyze at room temperature for 15 minutes;

[0035] (2) Magnetic separator Fe 3 o 4 Preparation: Take FeCl 3 •6H 2 O was dissolved in deionized water, and then transferred to a three-necked flask, and N was added dropwise under ultrasonic and stirring conditions. 2 h 4 •H 2 O, ultrasonic stirring continued after the dropwise addition; FeSO was added dropwise under ultrasonic 4 •7H 2 O solution, ultrasonically stirred at room temperature for 10 min; then NH was added dropwise to the solution 3 •H 2 O, adjust pH=9 with deionized water, then stir at room temperature for 30 min; after stirring, then perform magnetic separation, wash the reaction product with dei...

Embodiment 3

[0038] A method for treating heavy metal copper ions with a combined adsorbent in industrial sewage is characterized in that it comprises the following steps:

[0039] (1) Preparation of adsorption carrier: Dissolve tofu chai pectin in deionized water, adjust pH to 8 with sodium hydroxide solution, stir and hydrolyze at room temperature for 20 minutes;

[0040] (2) Magnetic separator Fe 3 o 4 Preparation: Take FeCl 3 •6H 2 O was dissolved in deionized water, and then transferred to a three-necked flask, and N was added dropwise under ultrasonic and stirring conditions.2 h 4 •H 2 O, ultrasonic stirring continued after the dropwise addition; FeSO was added dropwise under ultrasonic 4 •7H 2 O solution, ultrasonically stirred at room temperature for 10 min; then NH was added dropwise to the solution 3 •H 2 O, adjust pH=9 with deionized water, then stir at room temperature for 30 min; after stirring, then perform magnetic separation, wash the reaction product with deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com