Preparation method and application of rod-like ozone catalyst Cu-OMS-2

A technology of cu-oms-2 and catalyst, which is applied in the field of water pollution control, can solve the problems of complicated ozone catalytic oxidation process, increased water treatment cost, and reduced catalyst activity, achieving low metal ion dissolution concentration and stable reuse performance , Lattice oxygen flow performance large effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

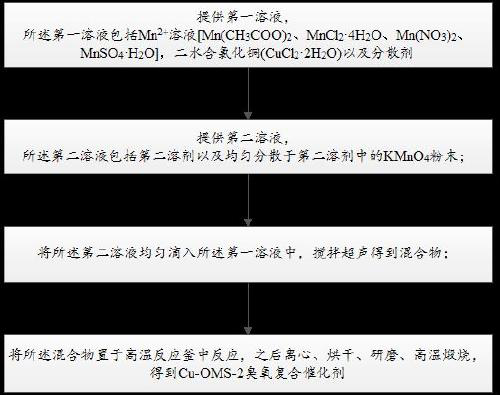

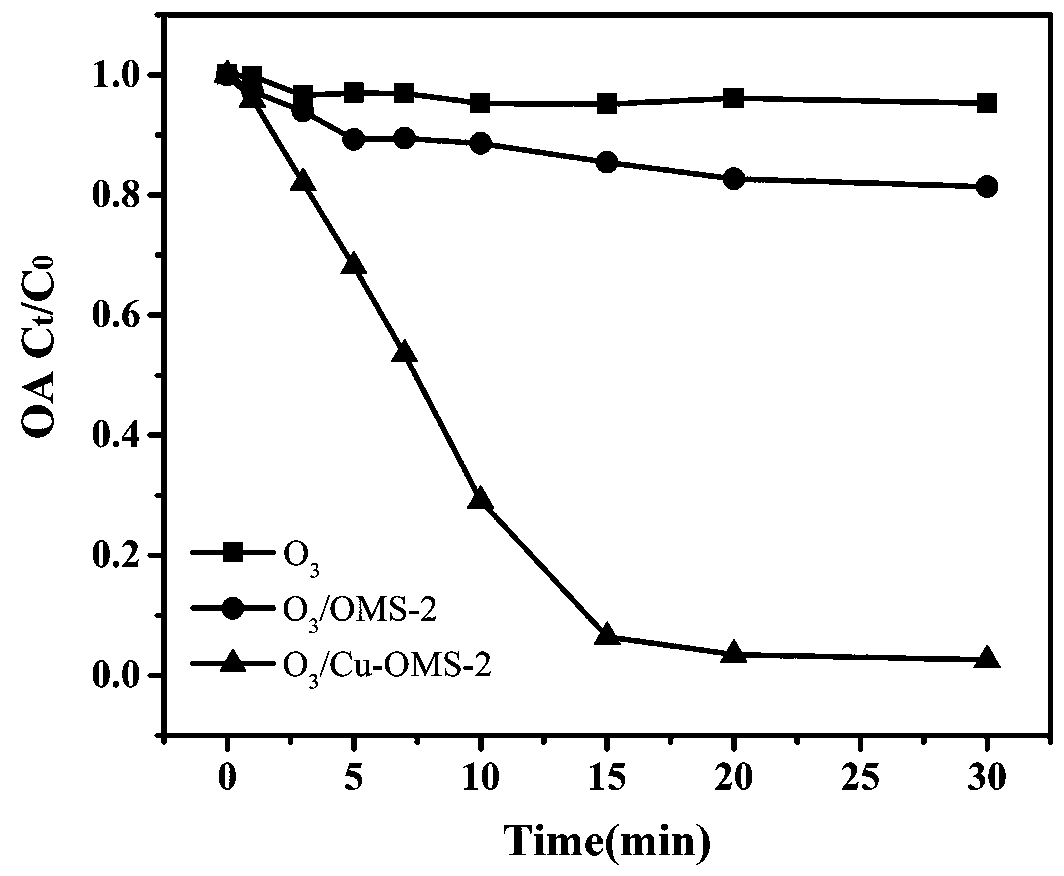

[0032] Such as figure 1 Shown, the preparation method of the embodiment of the present invention Cu-OMS-2 ozone catalyst, described method comprises the steps:

[0033] providing a first solution comprising Mn 2+ solution, CuCl 2 2H 2 O and dispersant;

[0034] providing a second solution comprising a second solvent and KMnO uniformly dispersed in the second solvent 4 powder;

[0035] uniformly drop the second solution into the first solution, stir and sonicate to obtain a mixture;

[0036] The mixture is subjected to hydrothermal reaction, and then centrifuged, dried, ground and calcined at a high temperature to obtain a Cu-OMS-2 ozone composite catalyst.

[0037] OMS-2 is a pore size of 0.46 nm, made of [MnO 6 ] Manganese oxide with a one-dimensional pore frame structure with shared edges in the octahedral chain. There are manganese ions in various valence states in its skeleton, and there are a large number of open interlayer and pore structures, which can provide a...

Embodiment 1

[0044] Preparation of Cu-OMS-2

[0045] First weigh 3.668 g of Mn(CH 3 COO) 2 with 1.277 g of CuCl 2 2H 2 O, supplemented by stirring at a speed of 500-600 r / min, so that it was completely dissolved in 35 mL of deionized water, and then 2.5 mL of acetic acid was added to adjust the pH; another 2.168 g KMnO 4 Stir fully at the same speed and completely dissolve in 40 mL deionized water; then KMnO 4 The solution was added dropwise with Mn(CH 3 COO) 2 solution; ultrasonicated for 10 min, transferred to a 100 mL autoclave, placed in an oven to synthesize at 140°C for 24 h, cooled to room temperature, taken out, centrifuged and washed several times until neutral, and then dried in an oven at 100°C for 12 h h, the obtained solid was ground, and finally put into a muffle furnace, calcined at 400 °C for 4 h at a heating rate of 4 °C / min, and then ground to obtain the desired catalyst.

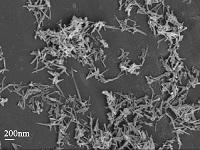

[0046] The SEM photo of Cu-OMS-2 prepared by the embodiment of the present invention 1 is as...

Embodiment 2

[0050] Preparation of Cu-OMS-2

[0051] First weigh 3.668 g of Mn(CH 3 COO) 2 with 0.267 g of CuCl 2 2H 2 O, supplemented by stirring at a speed of 500-600 r / min, so that it was completely dissolved in 35 mL of deionized water, and then 2.5 mL of acetic acid was added to adjust the pH; another 2.168 g KMnO 4 Stir fully at the same speed and completely dissolve in 40 mL deionized water; then KMnO 4 The solution was added dropwise with Mn(CH 3 COO) 2 solution; ultrasonicated for 10 min, transferred to a 100 mL autoclave, placed in an oven and synthesized at 100°C for 24 h, cooled to room temperature, taken out, centrifuged and washed several times until neutral, and then dried in an oven at 100°C for 12 h h, the obtained solid was ground, and finally put into a muffle furnace, calcined at 400 °C for 4 h at a heating rate of 4 °C / min, and then ground to obtain the desired catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com