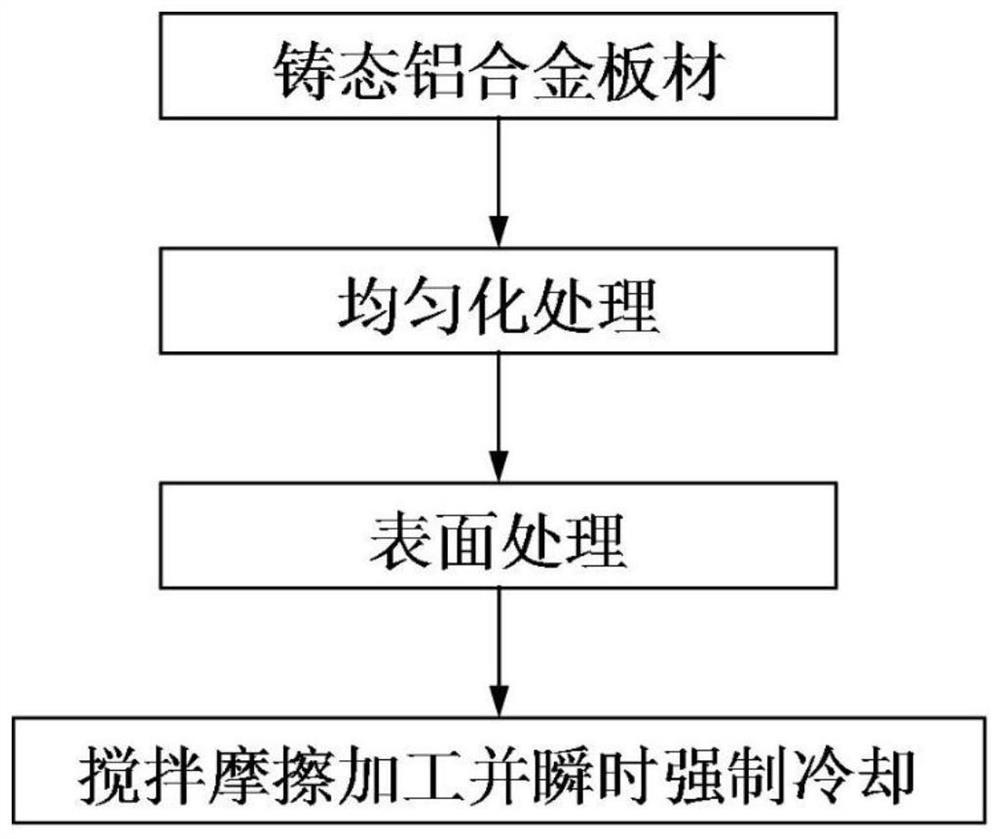

A plastic processing method to improve the comprehensive mechanical properties of 2a14 aluminum alloy sheet

A technology of aluminum alloy plate and comprehensive mechanics, which is applied in the field of aluminum alloy processing, can solve the problems of poor comprehensive mechanical properties of aluminum alloy, and achieve the effects of shortening high temperature residence time, improving fluidity and uniform plastic rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Homogenization treatment: saw the as-cast 2A14 aluminum alloy sheet to be processed according to the equipment size requirements to 150mm×300mm×5mm, put the sawed sheet in a furnace at room temperature, and homogenize it at 480°C for 12 hours. Cool the furnace to 160±2°C, then take it out of the heat treatment furnace and air cool to room temperature;

[0028] Surface treatment: After the homogenization treatment, the surface of the 2A14 aluminum alloy plate to be processed is polished with a grinder, physically cleaned (cleaned by water-based cleaning agent), rinsed with water, and then dried with a hair dryer for later use;

[0029] Friction stir processing: clamp the surface-treated 2A14 aluminum alloy plate to the friction stir welding equipment for single-pass friction stir processing, and instantaneously force cooling. The cooling liquid is flowing water at 24±2°C for edge friction stir processing Cool on the side.

[0030] Machining treatment: The 2A14 aluminum ...

Embodiment 2

[0032] Homogenization treatment: saw the as-cast 2A14 aluminum alloy plate to be processed according to the equipment size requirements to 150mm×300mm×5mm, put the sawed plate in a furnace at room temperature, and homogenize it at 460°C for 14 hours. Cool the furnace to 160±2°C, then take it out of the heat treatment furnace and air cool to room temperature;

[0033] Surface treatment: Use a grinder to polish the surface of the homogenized 2A14 aluminum alloy plate to be processed, rinse it with water after physical cleaning, and then dry it with a hair dryer for later use;

[0034] Friction stir processing: Clamp the surface-treated 2A14 aluminum alloy plate to the friction stir welding equipment for single-pass friction stir processing and instantaneous forced cooling. The cooling liquid is flowing water at 24±2°C. cool down.

[0035] Machining treatment: The 2A14 aluminum alloy sheet after friction stir processing is machined to remove the non-friction stir processing area...

Embodiment 3

[0037] Homogenization treatment: saw the as-cast 2A14 aluminum alloy sheet to be processed according to the equipment size requirements to 150mm×300mm×5mm, put the sawn sheet into a furnace at room temperature, and homogenize it at 490°C for 10 hours. Cool the furnace to 160±2°C, then take it out of the heat treatment furnace and air cool to room temperature;

[0038] Surface treatment: Use a grinder to polish the surface of the homogenized 2A14 aluminum alloy plate to be processed, rinse it with water after physical cleaning, and then dry it with a hair dryer for later use;

[0039] Friction stir processing: Clamp the surface-treated 2A14 aluminum alloy plate to the friction stir welding equipment for single-pass friction stir processing and instantaneous forced cooling. The cooling liquid is flowing ice water at 2±2°C for edge friction stir processing Cool on the side.

[0040] Machining treatment: The 2A14 aluminum alloy sheet after friction stir processing is machined to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com