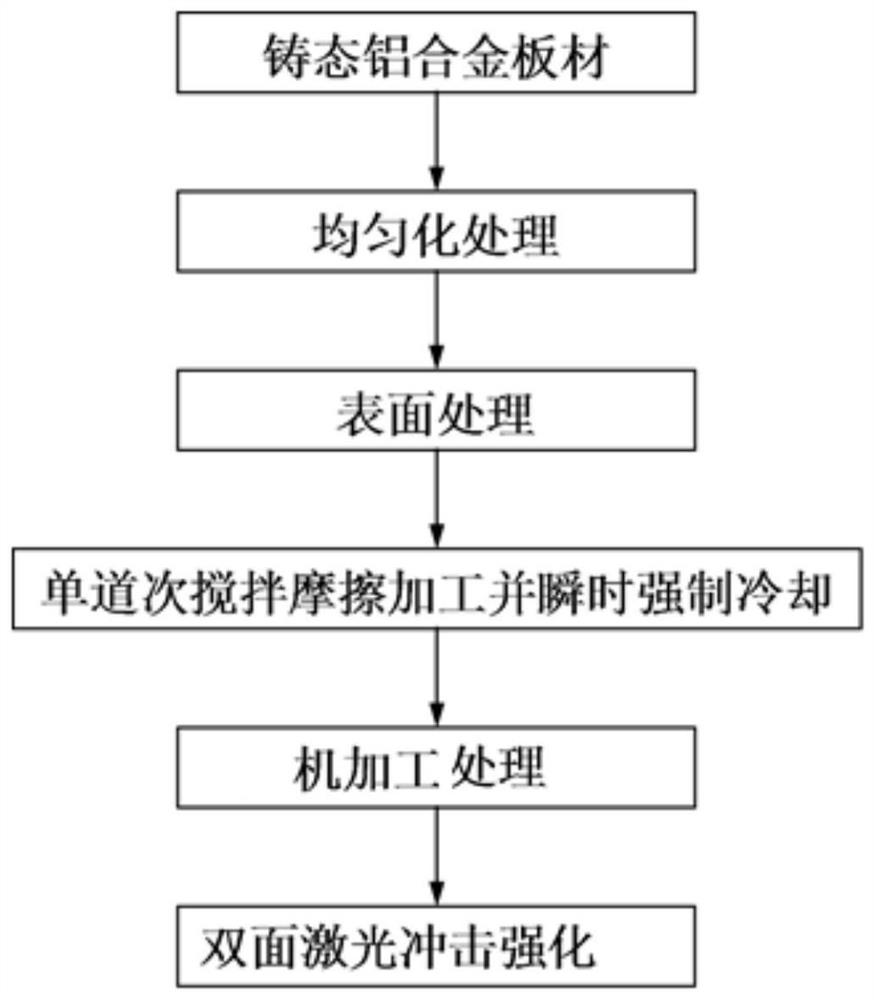

A method for plastic forming of high-strength wear-resistant aluminum alloy plate

A technology for plastic forming of aluminum alloy plates, applied in the field of local modification of aluminum alloy plates and large surface plastic forming, and plastic forming of high-strength wear-resistant aluminum alloy plates, can solve the problems of poor wear resistance and low local strength, and achieve Improved wear resistance, uniform distribution of the second phase, and improved heat dissipation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

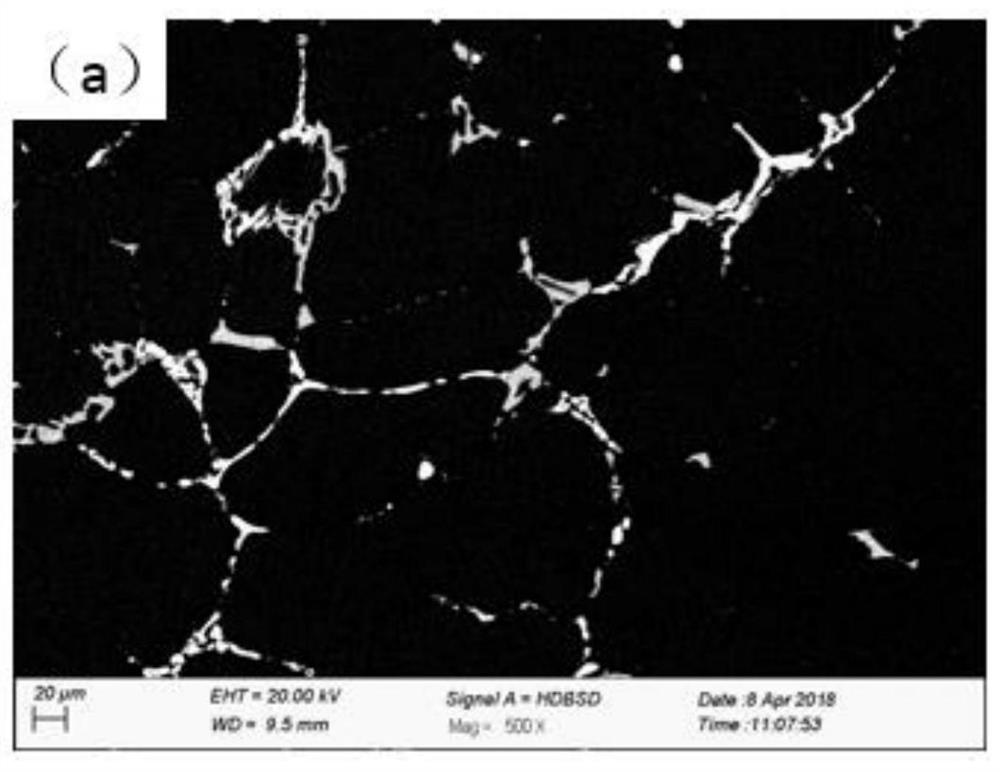

[0029] (1) Homogenization treatment: saw the as-cast 2A14 aluminum alloy plate to be processed according to the equipment size requirements to 150mm×300mm×5mm, put the sawed plate in a furnace at room temperature, and homogenize it at 490°C for 10 hours, and the heat preservation is over Then cool down to 160±2°C with the furnace, and then take it out of the heat treatment furnace and air cool to room temperature;

[0030] (2) Surface treatment: After homogenization treatment, the surface of the 2A14 aluminum alloy plate to be processed is polished with a grinder, washed with a water-based detergent and rinsed with water, and then dried with a hair dryer for later use.

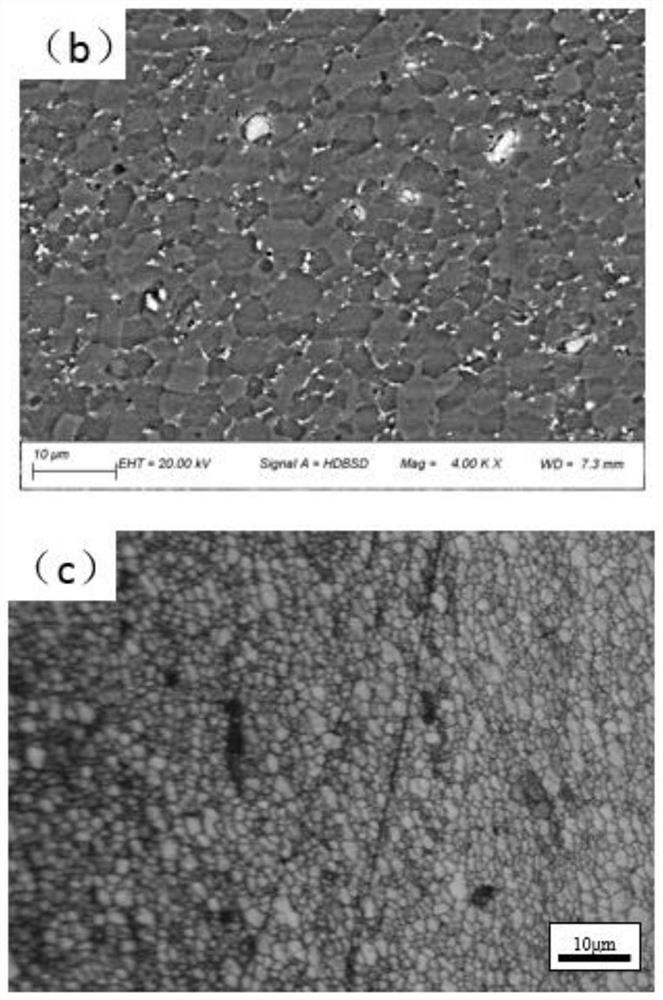

[0031] (3) Friction stir processing: clamp the surface-treated 2A14 aluminum alloy plate on the friction stir welding equipment for single-pass friction stir processing, and use 24±2°C flowing water to cool while stirring. The friction stir processing parameters The rotation speed is 1000rpm, the feed rate is ...

Embodiment 2

[0035] (1) Homogenization treatment: saw the as-cast 2A14 aluminum alloy plate to be processed according to the equipment size requirements to 150mm×300mm×5mm, put the sawn plate in a furnace at room temperature, and homogenize it at 460°C for 14 hours, and the heat preservation is over Then cool down to 160±2°C with the furnace, and then take it out of the heat treatment furnace and air cool to room temperature;

[0036] (2) Surface treatment: The surface of the 2A14 aluminum alloy plate to be processed after the homogenization treatment is polished with a grinder, washed with a water-based detergent and rinsed with water, and then dried with a hair dryer for later use.

[0037] (3) Friction stir processing: clamp the surface-treated 2A14 aluminum alloy plate on the friction stir welding equipment for single-pass friction stir processing, and use 24±2°C flowing water to cool while stirring. The friction stir processing parameters The rotation speed is 800rpm, the feed speed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com