Hot isostatic pressure diffusion connection method for tungsten or tungsten alloy and high-strength steel

A hot isostatic pressing diffusion, high-strength steel technology, applied in welding equipment, metal processing equipment, pressure inorganic powder coating, etc. The effect of high tensile strength, good bonding performance and enhanced mechanical properties of welded joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

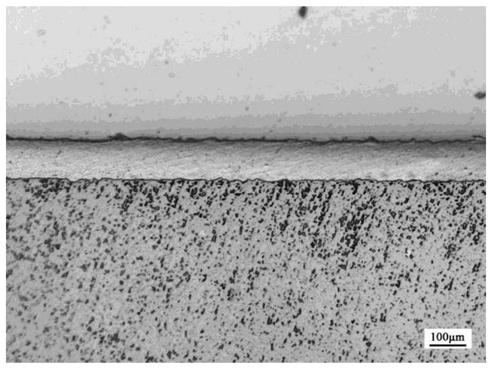

Image

Examples

Embodiment 1

[0049] A hot isostatic pressure diffusion bonding method for tungsten or tungsten alloy and high-strength steel, using 35CrMnSiA steel with a sample size of Φ60mm×20mm to connect with 91 tungsten-nickel-iron alloy, characterized in that its specific steps are as follows :

[0050] a. Cleaning before welding:

[0051] Use 80#, 200#, 400# and 800# sandpaper to grind the surface to be connected of 35CrMnSiA steel and 91 tungsten-nickel-iron alloy step by step, then put it into acetone for ultrasonic cleaning for 10min, and then dry it. 91 tungsten-nickel-iron alloy sealed preservation;

[0052] b. Preparation of transition layer:

[0053] b-1. Sandblasting the pure tungsten to be sprayed:

[0054] Brown corundum with a particle size of 80 mesh is used as the sandblasting material, the sandblasting angle is 60°, and the compressed gas pressure is 0.8MPa;

[0055] Keep the temperature of the workpiece at 60°C during the blasting process;

[0056] b-2. The workpiece after sandb...

Embodiment 2

[0065] A hot isostatic pressing diffusion bonding method for tungsten or tungsten alloy and high-strength steel, using 60Si2Mn steel with a sample size of Φ30mm×10mm to connect with 99.9% pure tungsten, characterized in that its specific steps as follows:

[0066] a. Cleaning before welding:

[0067] Use 80#, 200#, 400# and 800# sandpaper to grind the surface to be connected between 60Si2Mn steel and 99.9% pure tungsten step by step, then put it into acetone for ultrasonic cleaning for 15 minutes, and then dry it. The cleaned 60Si2Mn steel Sealed with 99.9% pure tungsten;

[0068] b. Preparation of transition layer:

[0069] b-1. 99.9% pure tungsten to be sprayed is sandblasted:

[0070] White corundum with a particle size of 60 mesh is used as the sandblasting material, the sandblasting angle is 60°, and the compressed gas pressure is 0.8MPa;

[0071] Keep the temperature of the workpiece at 75°C during the blasting process;

[0072] b-2. The workpiece after sandblasting...

Embodiment 3

[0081] A hot isostatic pressing diffusion bonding method for tungsten or tungsten alloy and high-strength steel, with sample size such as Figure 4 The 30CrMnSiNi2A steel with the special-shaped curved surface structure shown is connected with 99.9% pure tungsten. It is characterized in that its specific steps are as follows:

[0082] a. Cleaning before welding:

[0083] Use 80#, 200#, 400# and 800# sandpaper to grind the surface to be connected of 30CrMnSiNi2A steel and 99.9% pure tungsten step by step, then put it into acetone for ultrasonic cleaning for 15 minutes, and then dry it. The cleaned 30CrMnSiNi2A steel and 99.9% pure tungsten sealed preservation;

[0084] b. Preparation of transition layer:

[0085] b-1. Sand blasting treatment for 99.9% pure tungsten to be sprayed:

[0086] Brown corundum with a particle size of 40 mesh is used as the sandblasting material, the sandblasting angle is 75°, and the compressed gas pressure is 0.6MPa;

[0087] Keep the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com