Electrolyzed water catalyst of nonconventional local area structure and preparation method thereof

An unconventional technology for electrolysis of water, applied in the direction of heterogeneous catalyst chemical elements, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as small specific surface area, hindering the practical application of perovskite, and high cost. Achieve high oxygen evolution reaction activity, suitable for large-scale preparation, and increase cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 LaNiO 3 Crystalline perovskite transforms into amorphous LaNiFe hydroxide

[0052] The specific preparation process of amorphous LaNiFe hydroxide is divided into two steps: LaNiO 3 Powder preparation, FeCl 3 Processing LaNiO 3 .

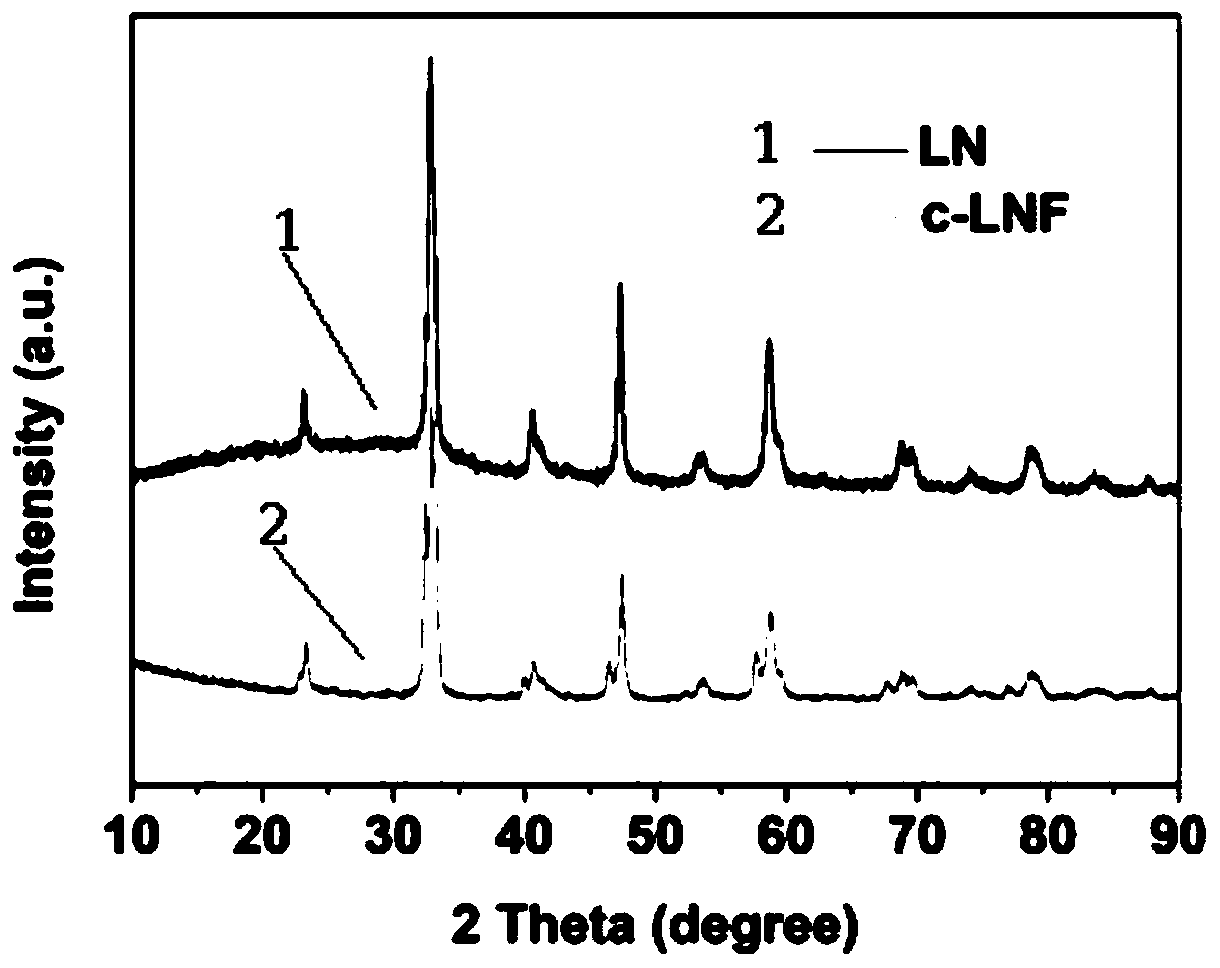

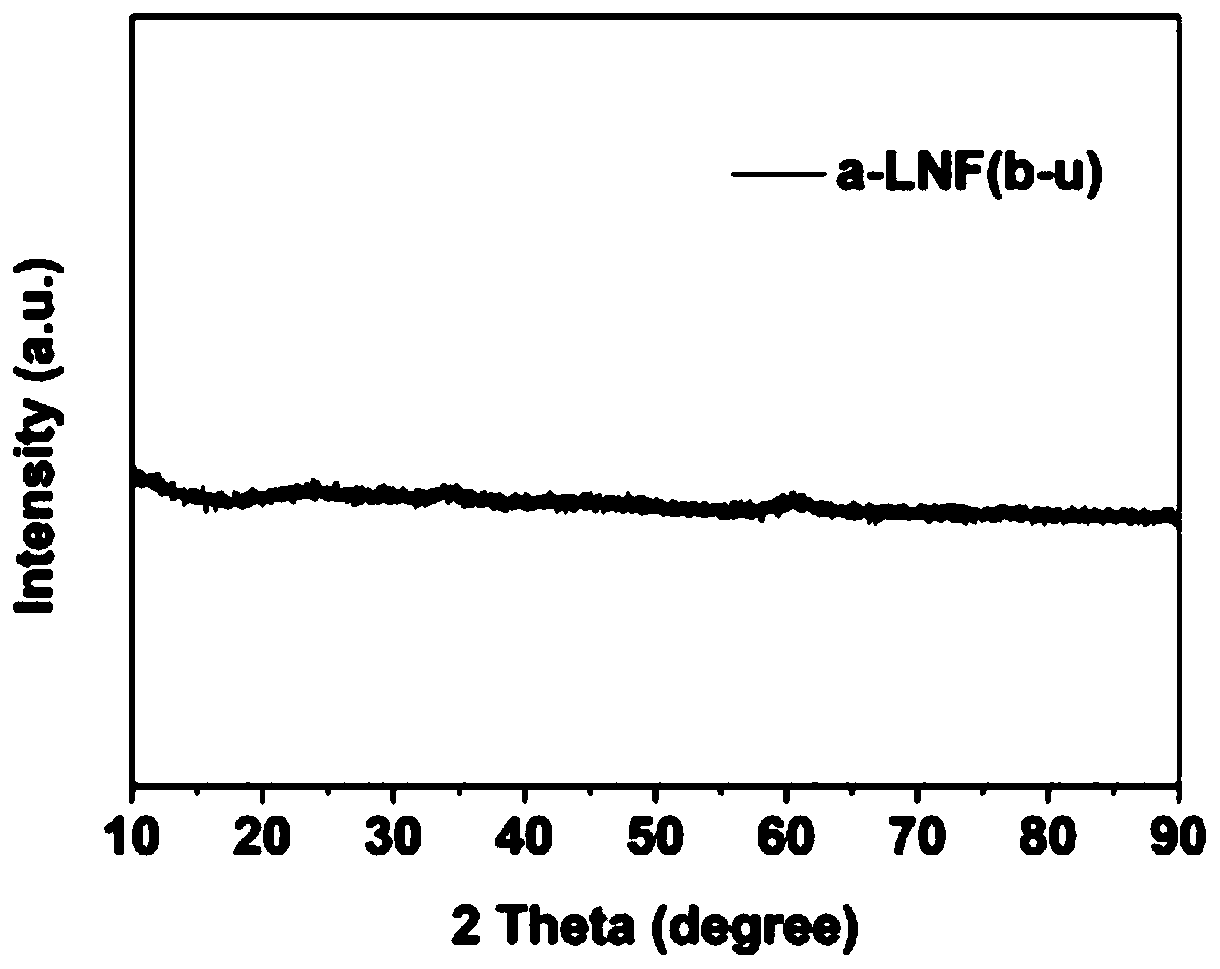

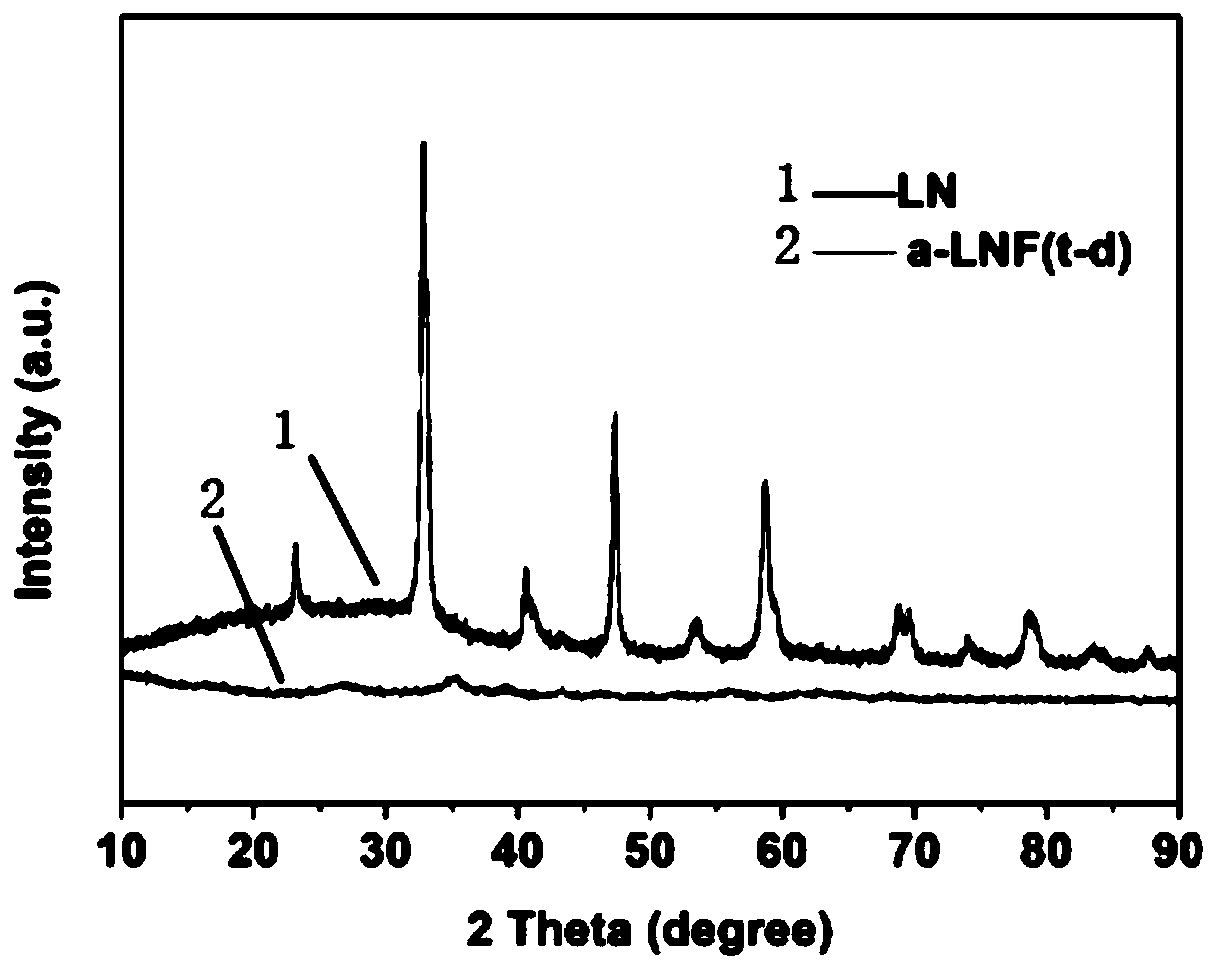

[0053] NeO 3 Preparation of powder: Weigh lanthanum oxide and nickel oxide with a La / Ni molar ratio of 1:1, use ethanol as a solvent, and ball mill for one hour; after drying the slurry, put it in a muffle furnace and burn it at 850°C, keep it warm After ten hours, crystallized LaNiO 3 Perovskite powder, its X-ray diffraction curve is as follows image 3 shown;

[0054] FeCl 3 Processing LaNiO 3 : Weigh 1 g of crystallized LaNiO 3 powder, placed in a solution containing 1.5 g FeCl 3 in aqueous solution, sonicated for 2 hours. Use a high-speed centrifuge at a speed of 10,000 rpm, wash with deionized water three times repeatedly, and collect the product. Raw LaNiO 3 And the XRD picture of the product such as image 3 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com