Calcium silicate nano hollow microsphere modified thermosensitive hydrogel and preparation method and application thereof

A temperature-sensitive hydrogel, hollow microsphere technology, applied in pharmaceutical formulations, prostheses, drug delivery, etc., can solve the problems of unfavorable application, high cytotoxicity, low specific surface area, etc., and achieves easy realization of reaction conditions and biocompatibility. Good, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of calcium magnesium silicate nano hollow microspheres modified temperature-sensitive hydrogel, comprising the steps of:

[0046] (1) Preparation of monodisperse nano-silica microspheres

[0047] Prepare monodisperse nano-silica microspheres according to the Stber method, that is: mix 150mL of absolute ethanol, 4mL of water and 12mL of ammonia (25wt%), ultrasonically vibrate for 15min, and record it as liquid A; (TEOS) was dissolved in 50mL of absolute ethanol, ultrasonically oscillated for 25min, and recorded as solution B. Stir liquid A at a constant temperature at 25°C for 10 minutes, then slowly pour into liquid B, react at 25°C for 8 hours until the solution becomes turbid, and collect it. The collected liquid is filtered and washed to obtain a filter residue, which is dried in a vacuum at 100°C Dry in the oven for more than 2 hours to obtain monodisperse nano-silica microspheres.

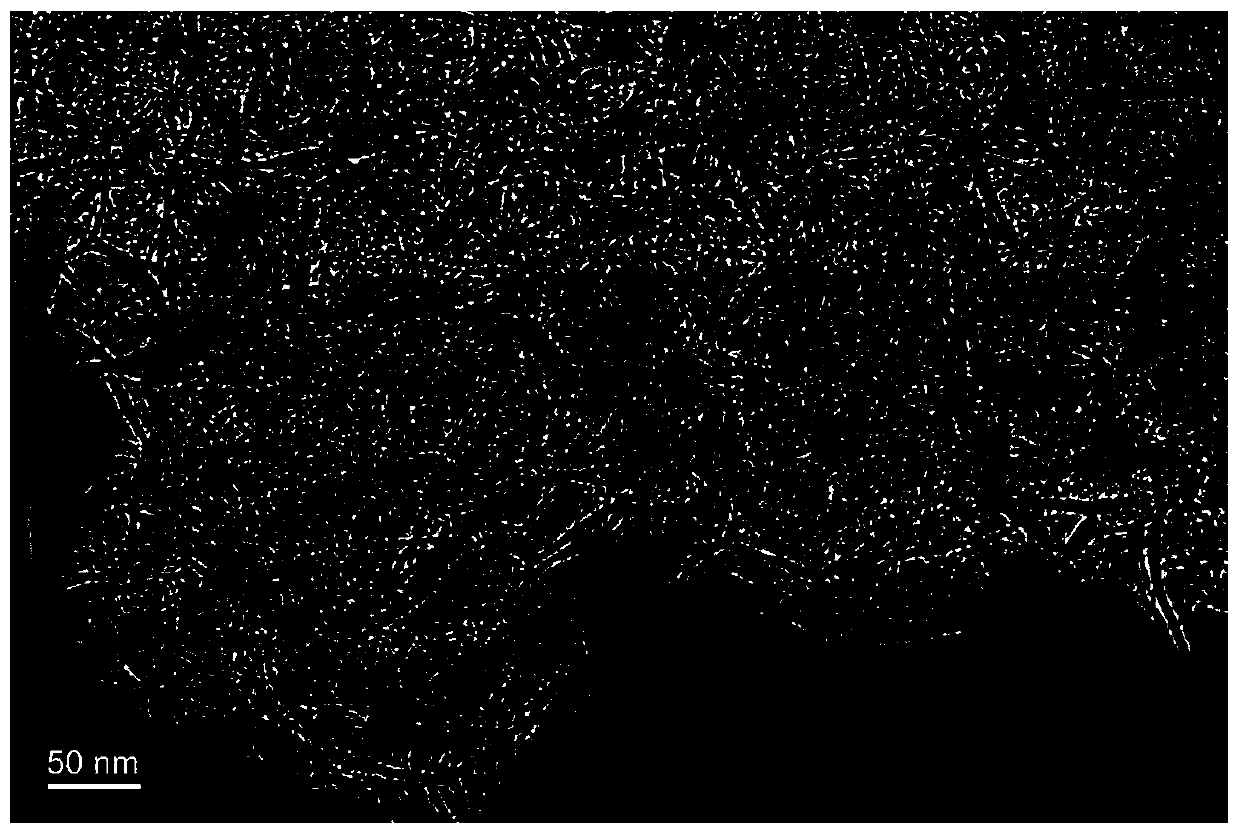

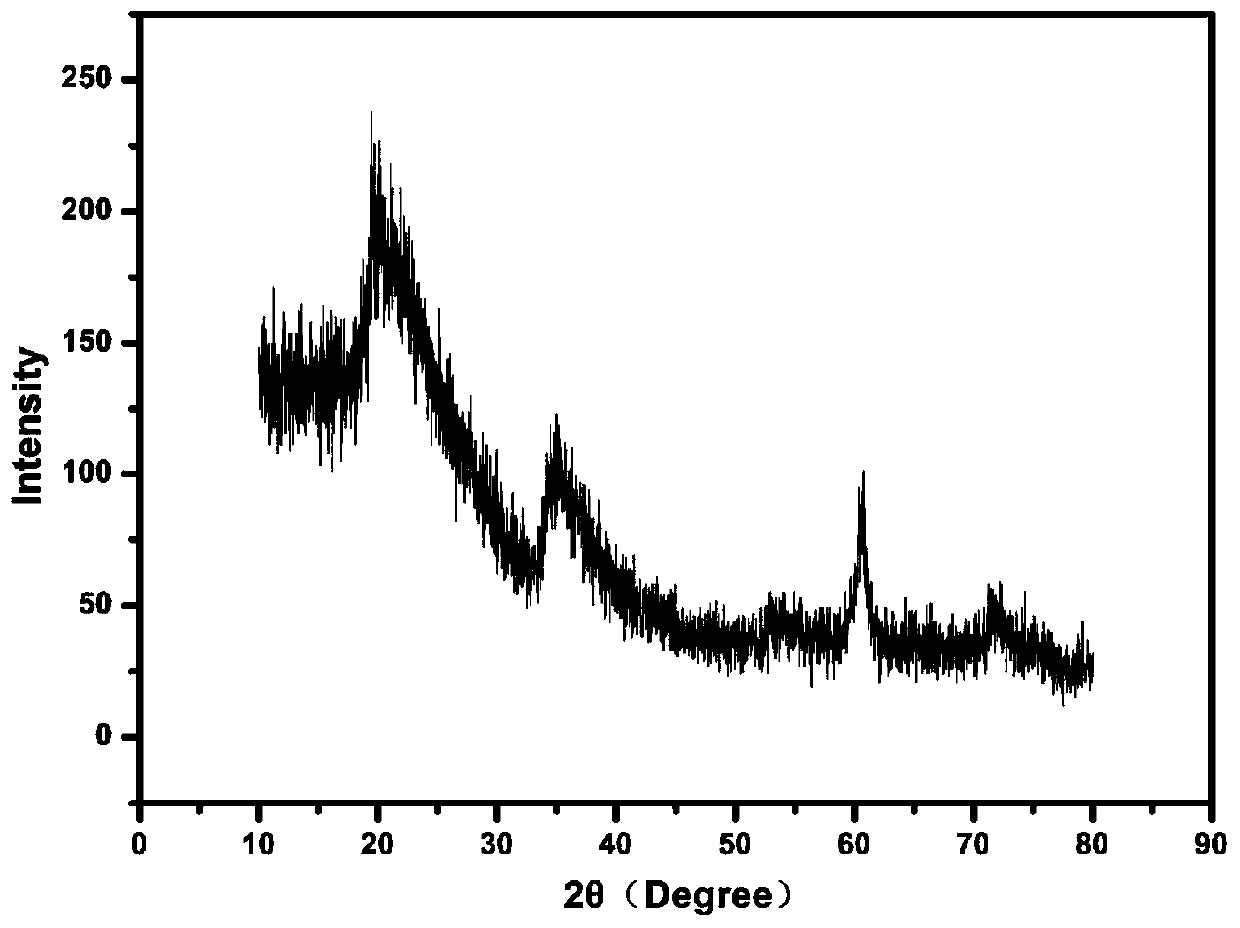

[0048] (2) Preparation of calcium magnesium silicate nano ho...

Embodiment 2

[0060] A preparation method of calcium magnesium silicate nano hollow microspheres modified temperature-sensitive hydrogel, comprising the steps of:

[0061] (1) Preparation of monodisperse nano-silica microspheres

[0062] As described in Example 1;

[0063] (2) Preparation of calcium magnesium silicate nano hollow spheres

[0064] Weigh 115mg MgCl 2 ·6H 2 O, 111 mg CaCl 2 and 276 mg NH 4 Cl was dissolved in 20 mL of deionized water, and 1 mL of ammonia water (25 wt %) was added and mixed evenly. 55 mg of the silica microspheres prepared in step (1) were uniformly dispersed in 20 mL of deionized water, and ultrasonically treated for 30 min. The above two solutions were mixed evenly and transferred to a 50 mL hydrothermal kettle, and reacted at 150° C. for 15 h. After the reaction is finished, it is naturally cooled to room temperature, filtered, washed alternately with deionized water and ethanol, and finally freeze-dried to obtain calcium-magnesium silicate hollow nan...

Embodiment 3

[0068] A preparation method of calcium magnesium silicate nano hollow microspheres modified temperature-sensitive hydrogel, comprising the steps of:

[0069] (1) Preparation of monodisperse nano-silica microspheres

[0070] As described in Example 1;

[0071] (2) Preparation of calcium magnesium silicate nano hollow spheres

[0072] Weigh 115mg MgCl 2 ·6H 2 O, 111 mg CaCl 2 and 276 mg NH 4 Cl was dissolved in 20 mL of deionized water, and 1 mL of ammonia water (25 wt %) was added and mixed evenly. 40 mg of the silica microspheres prepared in step (1) were uniformly dispersed in 20 mL of deionized water, and ultrasonically treated for 30 min. The above two solutions were mixed evenly and transferred to a 50 mL hydrothermal kettle, and reacted at 190° C. for 10 h. After the reaction is finished, it is naturally cooled to room temperature, filtered, washed alternately with deionized water and ethanol, and finally freeze-dried to obtain calcium-magnesium silicate hollow nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com