Preparation method and application of xanthan gum copolymer nano micelles

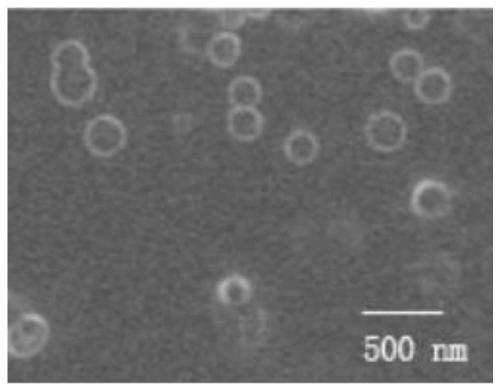

A technology of nano micelles and xanthan gum, which is applied in the directions of nanotechnology, nanomedicine, nanotechnology, etc., can solve the problems such as the degree of modification is not easy to control, the molecular weight of xanthan gum is large, and the distribution of nanoparticles is wide, and the shape of micelle is achieved. The effect of good regularity, controllable particle size and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Xanthan gum pretreatment: Weigh 1g of xanthan gum and add it to 200mL distilled water, stir to dissolve completely, make a solution with a mass concentration of 0.5w%, and place it in an ultrasonic environment with a power of 200W and an ultrasonic frequency of 20kHz Degrade for 2.5 hours; during the xanthan gum degradation process, use the NDJ-99 rotational viscometer to measure the dynamic viscosity of the modified xanthan gum solution, put the sample solution into a flat-bottomed centrifuge tube, select the S05 rotor, and set the rotational viscometer The parameters are used to measure the dynamic viscosity under different conditions. The viscosity measurement conditions are: 25°C, 60r / min. The initial dynamic viscosity of 0.5w% xanthan gum was 490mPa.s, which decreased to 110mPa·s after 2.5 hours of ultrasonication. Then the product is precipitated with ethanol, then dried at a constant temperature of 30°C, crushed, and sieved with a 100-mesh sieve;

[0022] (2...

Embodiment 2

[0029] Steps (1), (2) and (4) are the same as in Example 1. In step (3), the consumption of diacetone acrylamide is changed to 3 grams to obtain xanthan gum copolymer b. The remaining methods are the same to obtain xanthan gum Glue copolymer nanomicelle b1.

Embodiment 3

[0031] Steps (1), (2) and (4) are the same as in Example 1. In step (3), the consumption of diacetone acrylamide is changed to 4 grams to obtain xanthan gum copolymer c. The remaining methods are the same to obtain xanthan gum Glue copolymer nanomicelle c1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com