2,4-dinitrophenol fat emulsions and preparation method and application thereof

A technology of dinitrophenol and fat emulsion, applied in the field of medicine, can solve the problems of complicated production process of sustained-release preparations, inability to stop treatment in time, low flexibility, etc., and achieves increased product safety, patient compliance, and blood drug concentration. Easier to control and reduce the effect of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

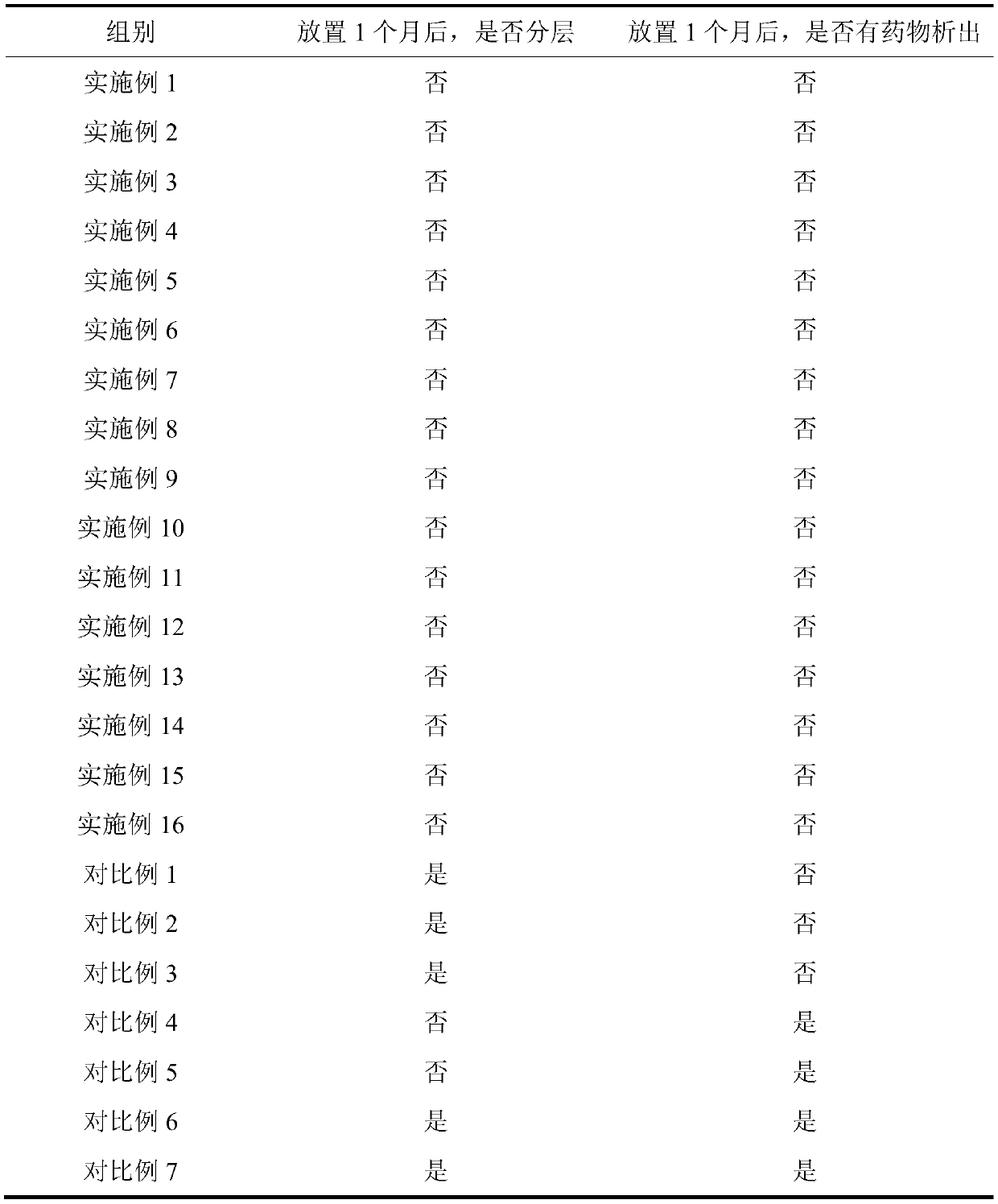

Examples

Embodiment 1

[0039] Embodiment 1, the preparation of 2,4-dinitrophenol fat emulsion of the present invention

[0040] Preparation of 1L 2,4-dinitrophenol fat emulsion: Weigh 100g of soybean oil and put it in a beaker, heat it to 60°C, add 12g of lecithin and 3g of 2,4-dinitrophenol into the soybean oil, 5000r / min high speed Stir to obtain an oily phase. Add 22.5 g of glycerin into the water for injection, and heat to 60° C. to dissolve to obtain an aqueous phase. Put the water phase and the oil at the same time into the mixer, stir at 10000r / min for 5min, stir into colostrum, homogenize the colostrum with high-pressure milk (800bar, 8 times), adjust the pH value to 6.5 with sodium hydroxide solution, and pack , 115 ° C autoclave for 30 minutes, you can.

Embodiment 2

[0041] Embodiment 2, the preparation of 2,4-dinitrophenol fat emulsion of the present invention

[0042] Preparation of 1L 2,4-dinitrophenol fat emulsion: Weigh 200g of soybean oil, put it in a beaker, heat to 60°C, add 12g of lecithin and 3g of 2,4-dinitrophenol into the soybean oil, and run at a high speed of 5000r / min Stir to obtain an oily phase. Add 22.5 g of glycerin into the water for injection, and heat to 60° C. to dissolve to obtain an aqueous phase. Put the water phase and the oil at the same time into the mixer, stir at 10000r / min for 5min, stir into colostrum, homogenize the colostrum with high-pressure milk (800bar, 8 times), adjust the pH value to 6.5 with sodium hydroxide solution, and pack , 115 ° C autoclave for 30 minutes, you can.

Embodiment 3

[0043] Embodiment 3, the preparation of 2,4-dinitrophenol fat emulsion of the present invention

[0044]Preparation of 1L 2,4-dinitrophenol fat emulsion: Weigh 300g of soybean oil and put it in a beaker, heat it to 60°C, add 12g of lecithin and 3g of 2,4-dinitrophenol into the soybean oil, 5000r / min high speed Stir to obtain an oily phase. Add 22.5 g of glycerin into the water for injection, and heat to 60° C. to dissolve to obtain an aqueous phase. Put the water phase and the oil at the same time into the mixer, stir at 10000r / min for 5min, stir into colostrum, homogenize the colostrum with high-pressure milk (800bar, 8 times), adjust the pH value to 6.5 with sodium hydroxide solution, and pack , 115 ° C autoclave for 30 minutes, you can.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap