A kind of food release agent improved by enzymatic method and preparation method thereof

A release agent and food technology, applied in the direction of dough anti-sticking, etc., can solve the problems of endangering the health of operators and consumers, affecting the health of operators, storage and transportation, inconvenience in use, etc. phenomenon, the effect of maintaining the quality of the release agent product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of a food release agent improved by an enzymatic method, wherein, comprising the following steps:

[0033] 1) Heat the beeswax to 70°C until it is completely dissolved, heat the edible vegetable oil to 70°C, and pretreat the compound lipase;

[0034] 2) adding edible vegetable oil, beeswax, phospholipid, cyclodextrin and glycerol monostearate into the mixing tank, mixing uniformly, then stirring and heating to 60 ℃~70 ℃ to obtain the first mixture;

[0035] 3) adding the compound lipase to the first mixture, stirring and reacting for 3-6 hours to obtain the second mixture;

[0036] 4) filtering the second mixture to obtain a solid and a filtrate, heating the filtrate to 85-95° C., stirring and reacting for 20-40 min to obtain a third mixture;

[0037] 5) Homogenize the third mixture through a homogenizer, quench it to below 25°C, and knead it; and

[0038] 6) Return the temperature of the product obtained in step 5) to 30° C. to 40° C., and ripen ...

Embodiment 1

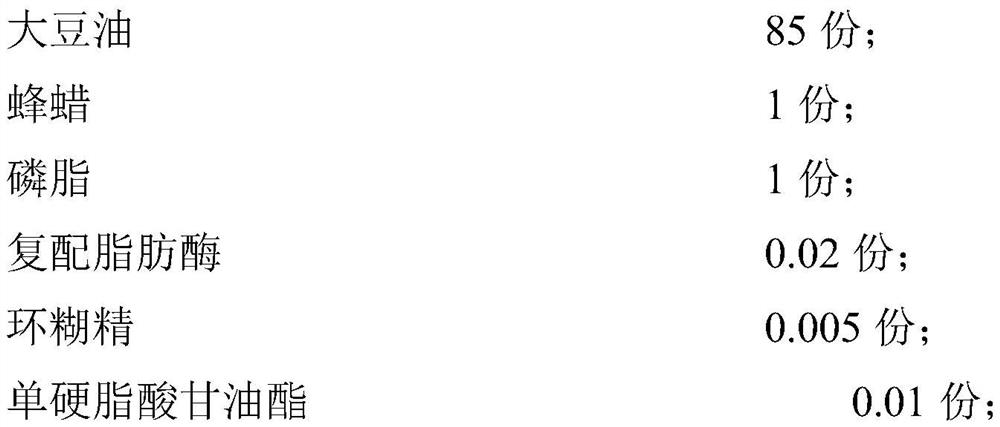

[0041] An enzymatically improved release agent for food, in parts by weight, comprising the following components:

[0042]

[0043] The phospholipids included 65wt% lecithin and 35wt% phosphatidylserine; the complex lipase included 15wt% phospholipase and 85wt% fatty triglyceride lipase.

[0044] A preparation method of an enzymatically improved food release agent, comprising the following steps:

[0045] 1) Heat the beeswax to 70°C until it is completely dissolved, heat the edible vegetable oil to 70°C, and pretreat the compound lipase;

[0046] 2) adding edible vegetable oil, beeswax, phospholipid, cyclodextrin and glyceryl monostearate into the mixing tank, mixing uniformly, then stirring and heating to 60° C. to obtain the first mixture;

[0047] 3) adding the compound lipase to the first mixture, stirring and reacting for 3h to obtain the second mixture;

[0048] 4) filtering the second mixture to obtain solid and filtrate, heating the filtrate to 85°C, and stirring ...

Embodiment 2

[0052] An enzymatically improved release agent for food, in parts by weight, comprising the following components:

[0053]

[0054] The phospholipids included 68 wt% lecithin and 32 wt% phosphatidylserine; the complex lipase included 20 wt% phospholipase and 80 wt% fatty triglyceride lipase.

[0055] A preparation method of an enzymatically improved food release agent, comprising the following steps:

[0056] 1) Heat the beeswax to 70°C until it is completely dissolved, heat the edible vegetable oil to 70°C, and pretreat the compound lipase;

[0057] 2) adding edible vegetable oil, beeswax, phospholipid, cyclodextrin and glyceryl monostearate into the mixing tank, mixing uniformly, then stirring and heating to 65° C. to obtain the first mixture;

[0058] 3) adding the compound lipase to the first mixture, stirring and reacting for 5h to obtain the second mixture;

[0059]4) Filtrating the second mixture to obtain a solid and a filtrate, heating the filtrate to 85-95° C., ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com