A negative electrode material for a high-capacity and long-life ternary lithium-ion battery

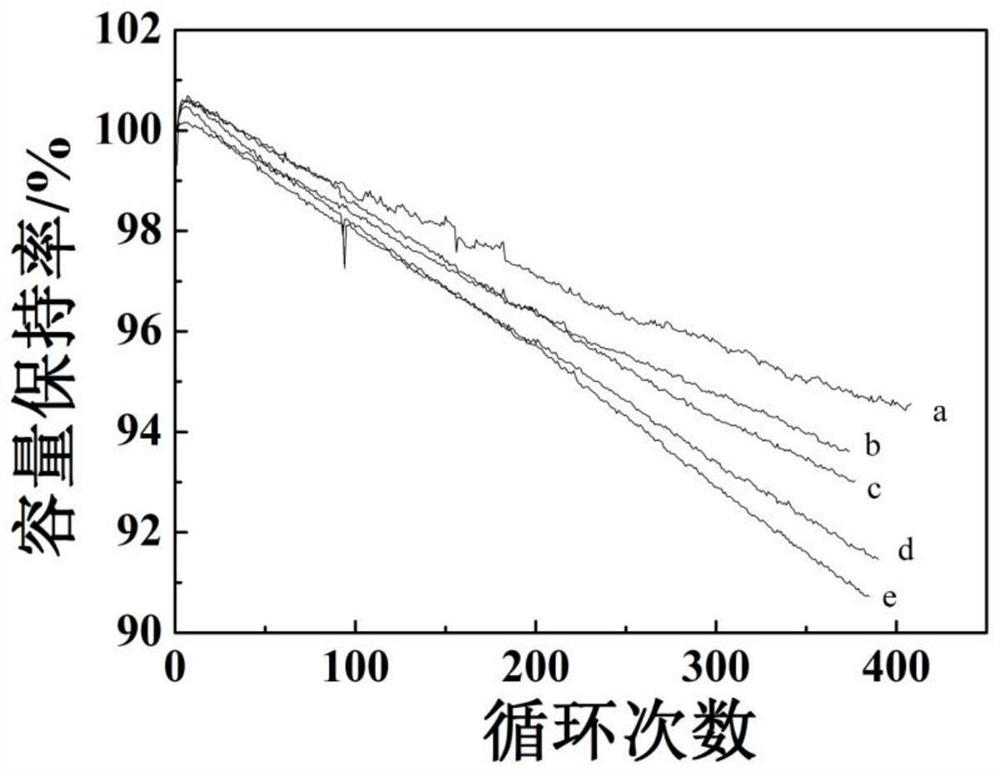

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of serious high-capacity ternary battery application and industrialization, poor processing performance of negative electrode slurry, and short battery life, etc. Achieve excellent charge and discharge stability, improve compaction density and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The negative electrode material of a high-capacity and long-life ternary lithium-ion battery proposed by the present invention is composed of the following raw material components: 92% composite graphite, 2.5% modified hydroxymethyl cellulose lithium, 2.5% conductive carbon black and 3% SBR.

[0023] Among them, composite graphite is composed of mesophase carbon microspheres (MCMB) and artificial graphite according to the mass ratio of 6:4; the particle size of mesophase carbon microspheres D 50 The range is 5 μm; artificial graphite is graphite after secondary granulation treatment, particle size D 50 The range is 15 μm.

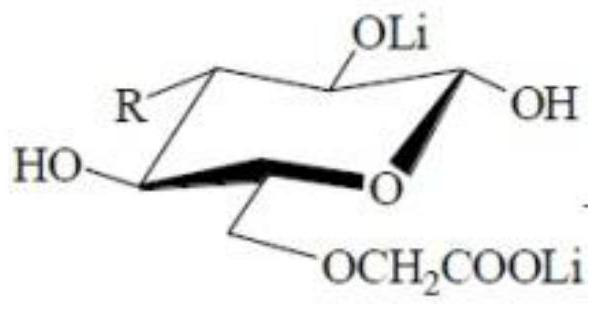

[0024] Wherein, the structural formula of modified hydroxymethyl cellulose lithium is:

[0025]

[0026] R is -OH, and the degree of substitution is 0.8.

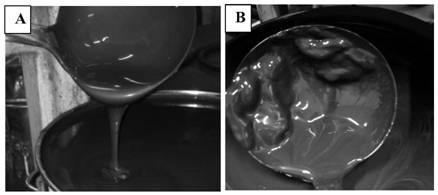

[0027] Preparation of the negative electrode pole piece: (1) Slurry: Glue the modified hydroxymethyl cellulose lithium, then add conductive carbon black, stir evenly, then add composite grap...

Embodiment 2

[0029] The negative electrode material of a high-capacity and long-life ternary lithium-ion battery proposed by the present invention is composed of the following raw material components: 97% composite graphite, 1% modified hydroxymethyl cellulose lithium, 1% conductive carbon black and 1% SBR.

[0030] Among them, composite graphite is composed of mesophase carbon microspheres and artificial graphite according to the mass ratio of 3:7; the particle size of mesophase carbon microspheres is D 50 The range is 10μm; artificial graphite is graphite after secondary granulation treatment, particle size D 50 The range is 20 μm.

[0031] Wherein, the structural formula of modified hydroxymethyl cellulose lithium is:

[0032]

[0033] R is for -OOCH 3 , the degree of substitution is 0.9.

[0034] Preparation of the negative electrode pole piece: (1) Slurry: Glue the modified hydroxymethyl cellulose lithium, then add conductive carbon black, stir evenly, then add composite graphi...

Embodiment 3

[0036] The negative electrode material of a high-capacity and long-life ternary lithium-ion battery proposed by the present invention is composed of the following raw material components: 89% composite graphite, 3% modified hydroxymethyl cellulose lithium, 3% conductive carbon black and 5% SBR.

[0037] Among them, composite graphite is composed of mesophase carbon microspheres and artificial graphite according to the mass ratio of 5:5; the particle size of mesophase carbon microspheres is D 50 The range is 15μm; artificial graphite is graphite after secondary granulation treatment, particle size D 50 The range is 25 μm.

[0038] Wherein, the structural formula of modified hydroxymethyl cellulose lithium is:

[0039]

[0040] R for -SO 3 H, the degree of substitution is 0.6.

[0041] Preparation of the negative electrode pole piece: (1) Slurry: Glue the modified hydroxymethyl cellulose lithium, then add conductive carbon black, stir evenly, then add composite graphite, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com