High-voltage lithium cobaltate positive electrode material, preparation method thereof and lithium-ion secondary battery

A high-voltage lithium cobalt oxide and cathode material technology, applied in the field of electrochemical energy storage, can solve problems such as many processes and poor interface stability, and achieve the effects of improving safety performance, inhibiting phase transition, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

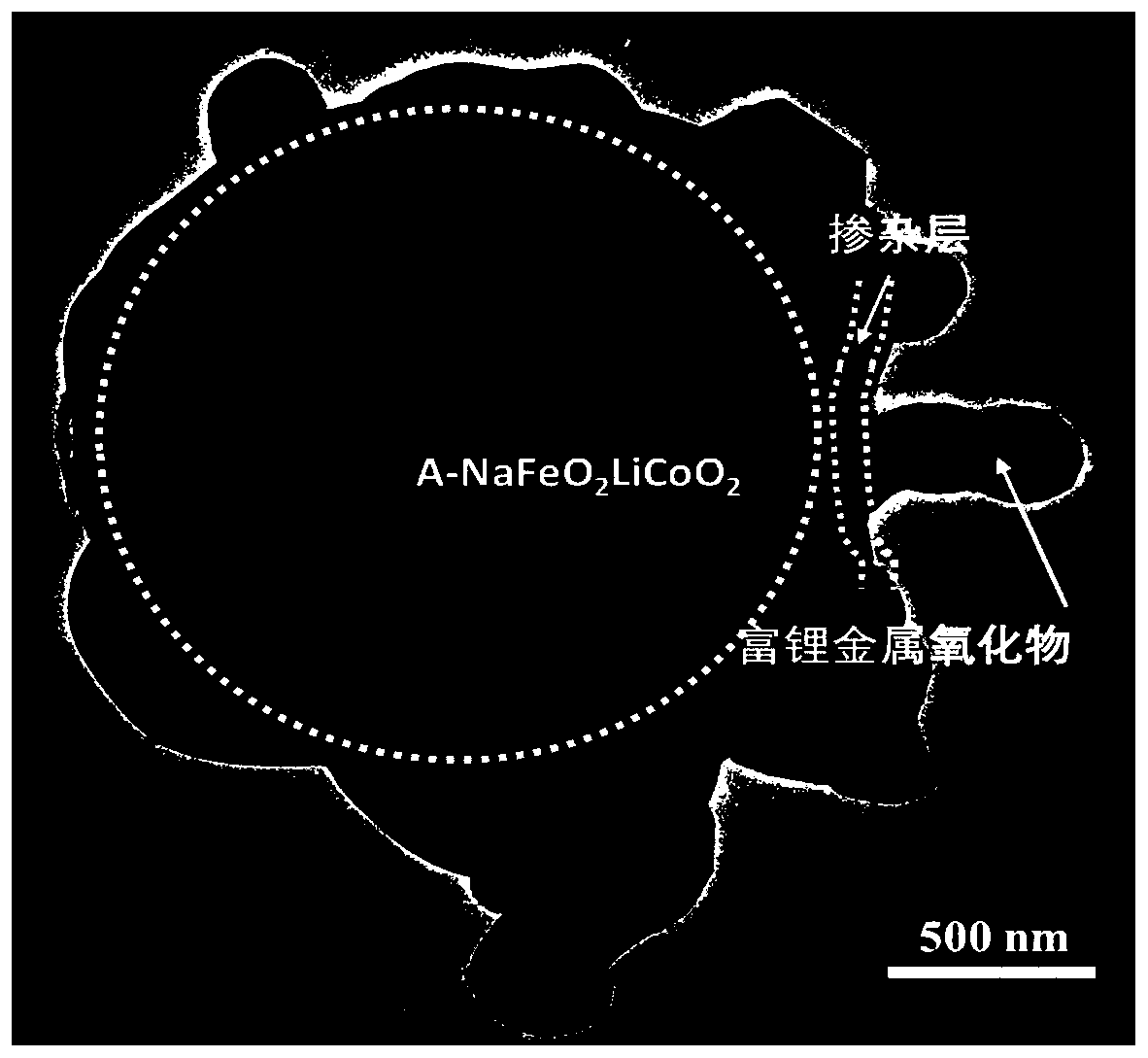

[0050] An embodiment of the present invention provides a method for preparing the above-mentioned high-voltage lithium cobaltate cathode material, which includes the following steps:

[0051] S1. Obtain lithium cobalt oxide material.

[0052] The lithium cobaltate material can be commercially available lithium cobaltate material, and can also be prepared by conventional methods, such as high-temperature solid-phase synthesis, sol-gel method, hydrothermal synthesis, precipitation-freezing method, etc., the present invention does not Specific limits.

[0053] S2. Add metal dopant, gelling agent and the lithium cobalt oxide material into the organic solvent, and mix uniformly to obtain a mixture; wherein, the solid content of the lithium cobalt oxide material in the mixture is 10-40 wt%. The sol-gel method is used to process the mixture, the reaction method is simple and the conditions are mild, which can make the mixing of doping elements more uniform, thereby reducing the size...

Embodiment 1

[0063] This embodiment provides a high-voltage lithium cobalt oxide positive electrode material, which is prepared according to the following steps:

[0064] Dissolve lithium hydroxide monohydrate in deionized water to obtain a 0.2 mol / L lithium hydroxide solution, add an equal volume of 0.2 mol / L cobalt nitrate aqueous solution, and continue stirring at 80°C until the water evaporates to dryness to obtain a dry powder , heat-treat the dry powder at 900°C for 12h to obtain lithium cobaltate particles with a particle size of 10-20μm.

[0065] Add 0.2g LiNO to 50g ethanol 3 , 2gZr(NO 3 ) 4 , 0.6gLa(NO 3 ) 3 , 5 g of citric acid and 10 g of lithium cobaltate particles were uniformly mixed by ultrasonic to obtain a mixture. The mixture was continuously stirred at 60°C until a viscous gel was formed, then loaded into a crucible, heat-treated at 200°C for 4 hours, and then sintered at 900°C for 12 hours to obtain a high-pressure lithium cobaltate cathode material.

Embodiment 2

[0067] This embodiment provides a high-voltage lithium cobalt oxide positive electrode material, which is prepared according to the following steps:

[0068] Dissolve lithium hydroxide monohydrate in deionized water to obtain a 0.2 mol / L lithium hydroxide solution, add an equal volume of 0.2 mol / L cobalt nitrate aqueous solution, and continue stirring at 80°C until the water evaporates to dryness to obtain a dry powder , heat-treat the dry powder at 900°C for 12h to obtain lithium cobaltate particles with a particle size of 10-20μm.

[0069] Add 0.2g LiNO to 50g ethanol 3 , 0.6gZr(NO 3 ) 4 , 0.6gLa(NO 3 ) 3 , 5 g of citric acid and 20 g of lithium cobaltate particles were uniformly mixed ultrasonically to obtain a mixture. The mixture was continuously stirred at 60°C until a viscous gel was formed, then loaded into a crucible, heat-treated at 400°C for 4 hours, and then sintered at 900°C for 12 hours to obtain a high-pressure lithium cobaltate cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com