Composite polyester staple fiber geotextile and preparation method

A polyester staple fiber and geotextile technology, which is applied in geotextiles, non-woven fabrics, textiles, and papermaking, can solve problems such as tearing, poor bursting force, and poor flame retardancy, and achieve good tear resistance stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

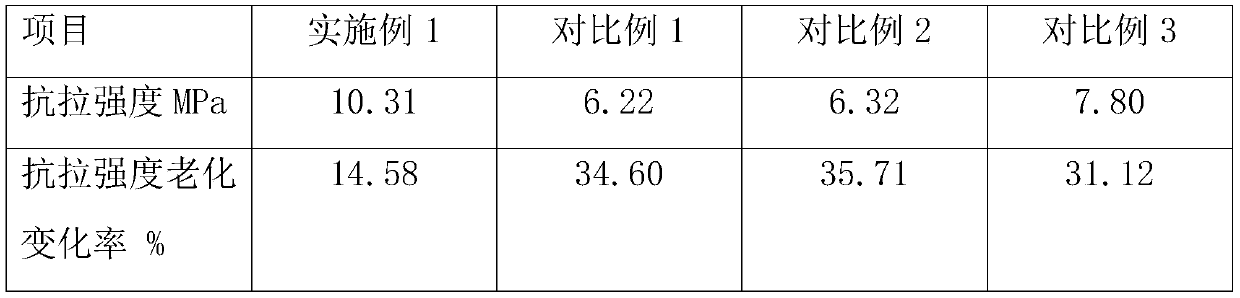

Embodiment 1

[0055] 1. Composition:

[0056] 88% polyester staple fiber, 9% polypropylene staple fiber, 3% polypropylene composite particles

[0057] 2. Set product parameters:

[0058] Surface density: 300±5g / cm 2

[0059] 3. Preparation method:

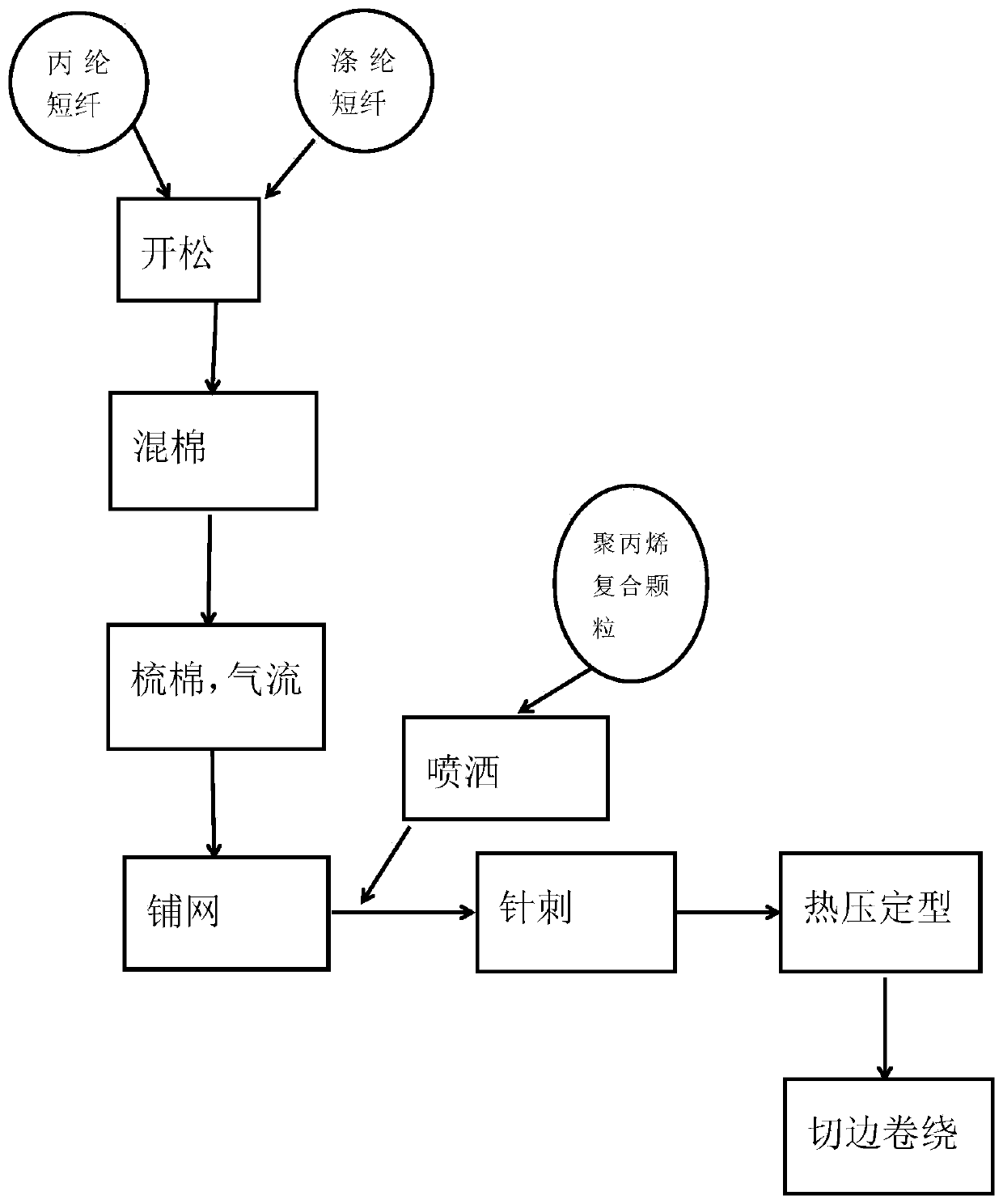

[0060] S01, sending the packaged polyester staple fiber and polypropylene staple fiber into the opening box for opening;

[0061] S02, sending the polyester staple fiber and the polypropylene staple fiber into the cotton mixing box for cotton mixing;

[0062] S03, use a carding machine to card the mixture, mechanically form a web, and send it to the web laying machine for web laying;

[0063] S04, using a pneumatic particle sprayer to evenly spray polypropylene composite particles on the net;

[0064] S05, using a needling machine for needling consolidation;

[0065] S06, use a heat press machine to carry out heat press setting;

[0066] S07, trimming and winding to obtain a composite polyester geotextile.

[0067] 4. Quantity of equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com