Powdery reinforcing material used for enhancing concrete structure strength

A technology for enhancing concrete and structural strength, applied in the field of concrete reinforcement materials, can solve the problems of concrete cracking, pulverization, easy sanding, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

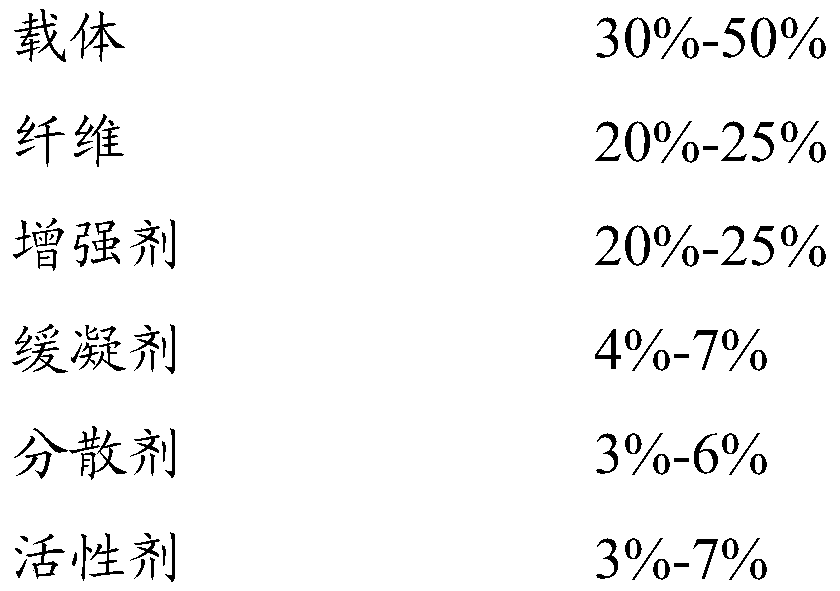

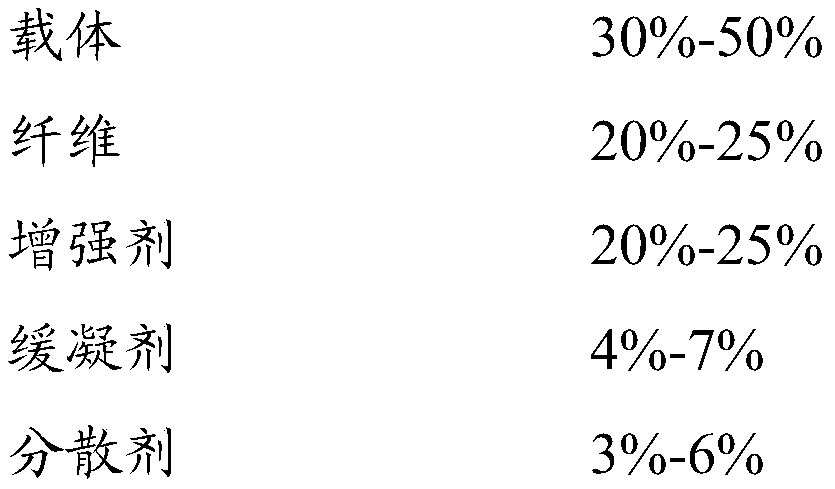

[0023] A powdery reinforcing material for strengthening the structural strength of concrete, comprising the following components according to mass percentage: 30% cement, 25% polypropylene fiber, 25% reinforcing agent (magnesium fluorosilicate: anhydrous sodium metasilicate: Zinc fluorosilicate is 7:4:9), retarder 7% (sodium gluconate: calcium sucrose: phosphorus slag powder and urea is 0.7:1.2:3:0.2), dispersant 6% (i.e. lignosulfonic acid sodium), active agent 7% (sodium dodecylbenzenesulfonate: sodium gluconate: starch 1:0.5:1.5).

Embodiment 2

[0025] A powdery reinforcing material for strengthening the strength of concrete structure, comprising the following components according to mass percentage: 40% fine sand, 20% steel fiber, 20% reinforcing agent (magnesium fluorosilicate: anhydrous sodium metasilicate: Zinc fluorosilicate is 7:5:10), retarder 7% (sodium gluconate: calcium sucrose: phosphorus slag powder and urea is 1:2:3:0.2), dispersant 6% (i.e. lignosulfonic acid sodium), active agent 7% (sodium dodecylbenzenesulfonate: sodium gluconate: starch 1:1:1.5).

Embodiment 3

[0027] A powdery reinforcing material for enhancing the structural strength of concrete, comprising the following components according to the mass percentage: fine sand and cement mixture 50%, carbon fiber 20%, reinforcing agent 20% (magnesium fluorosilicate: anhydrous metasilicate Sodium: zinc fluorosilicate is 10:5:9), retarder 4% (sodium gluconate: calcium sucrose: phosphorus slag powder and urea is 1.2:2:3:0.3), dispersant 3% (i.e. lignin sodium sulfonate), active agent 3% (sodium dodecylbenzenesulfonate: sodium gluconate: starch 1.3:1:5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com