A kind of sharpening method of arc-shaped diamond grinding wheel

A diamond grinding wheel, arc-shaped technology, applied in metal processing equipment, grinding machine parts, abrasive surface adjustment devices, etc., can solve the problems of low dressing efficiency, poor dressing quality, limited application range, etc., and achieve sharpening efficiency The effect of lifting, good appearance and uniform energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

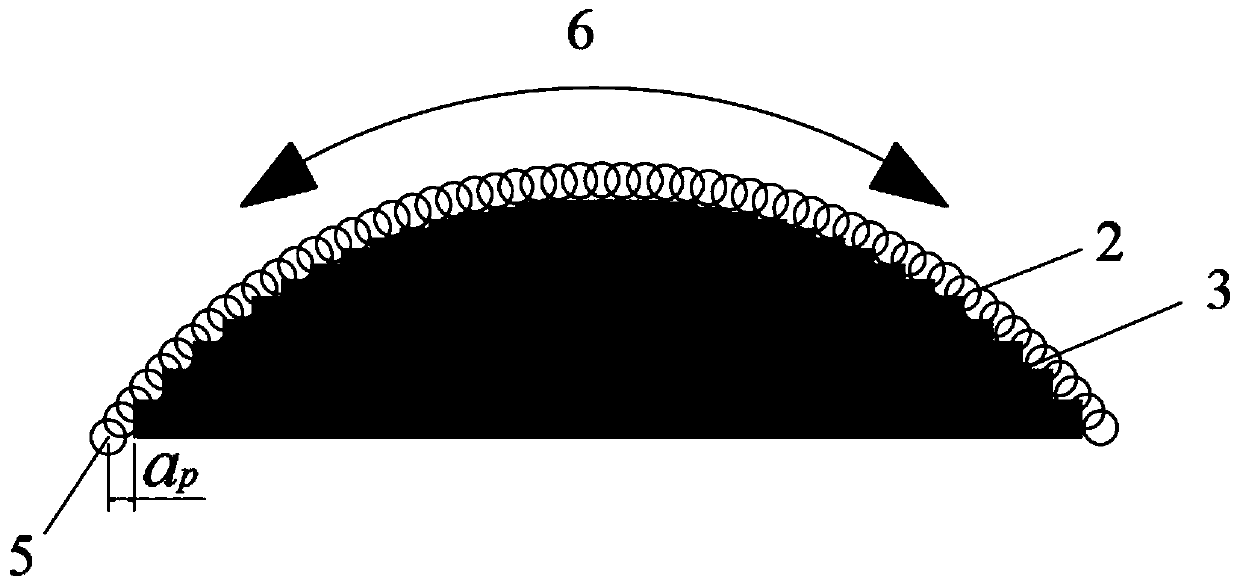

[0043] Such as Figure 1 to Figure 6 Shown, the sharpening method of a kind of arc-shaped diamond grinding wheel of the present invention comprises the following steps:

[0044] Step 1. On-site detection of the surface profile accuracy of the arc-shaped grinding wheel and tool calibration. The laser micrometer moves at a constant speed of 15mm / min to measure the grinding wheel rotating at 400rev / min. The sampling frequency is 50KHz and the sampling accuracy is 0.1μm. The obtained sampling points are the feature points of the height information on the arc surface of the grinding wheel, and the height information of the highest point is obtained by comparison, and the protrusion height of the highest point (denoted as t) is the total cutting depth of the laser water jet 2 on the grinding wheel surface in step 2 . Fine shaping tool setting position 5 is attached figure 1 As shown, adjust the relative position of the grinding wheel and the laser water beam so that the distance b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com