Circular-arc-shaped diamond grinding wheel dressing method

A diamond grinding wheel and arc-shaped technology, which is applied in the direction of metal processing equipment, grinding machine parts, laser welding equipment, etc., can solve the problems of poor dressing quality, low dressing efficiency, and limited application range, and achieve high dressing efficiency. Improved dressing efficiency and uniform energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Such as Figure 1 to Figure 12 Shown, the dressing method of a kind of arc-shaped diamond grinding wheel of the present invention, comprises the following steps:

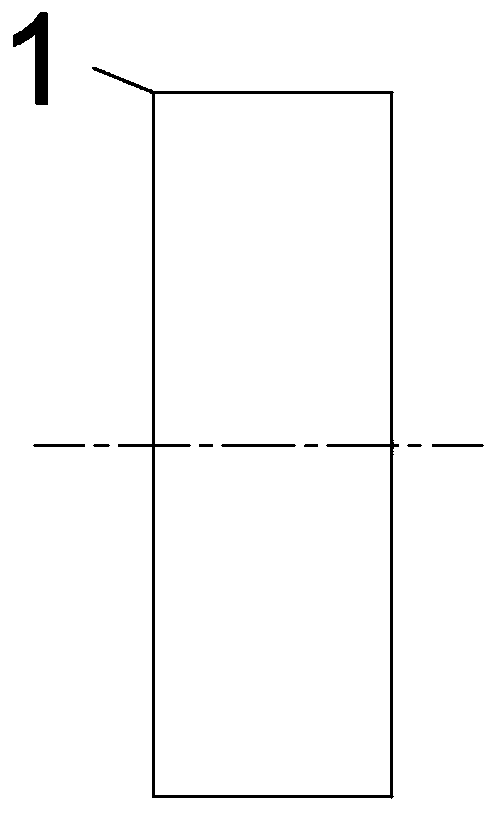

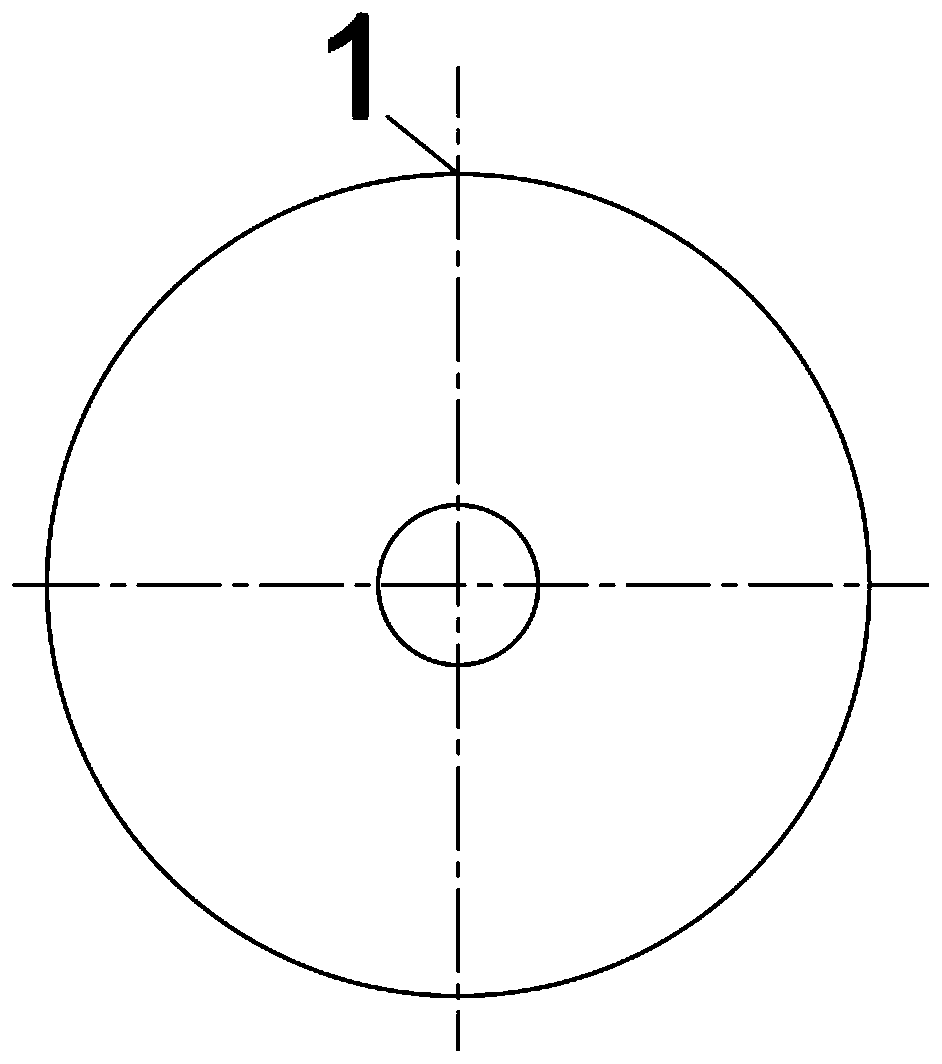

[0059] Step 1, set the smaller energy parameters of the micro-water guide laser and set the knife, the position 1 of rough shaping and knife setting is as attached Figure 1~3 As shown, the micro-water beam generating device and the grinding wheel are separately installed on the workpiece spindle and the grinding spindle of the three-axis linkage high-precision air-floating spindle grinder. The grinding wheel is driven by the grinding spindle to rotate, and the micro-water beam generating device works. The relative position of the main shaft makes the center line of the micro-water beam and the axis of the grinding wheel in the same vertical plane. Adjust the position coordinates of the workpiece main shaft so that the laser water beam 2 gradually moves closer to the grinding wheel. The AE signal source gene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com