Halogen-free resin composition for copper-clad laminate and preparation method thereof

A technology of resin composition and copper clad laminate, applied in the field of printed circuit boards, can solve the problems of low transition temperature and poor processing performance, achieve high glass transition temperature, increase heat resistance and improve heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

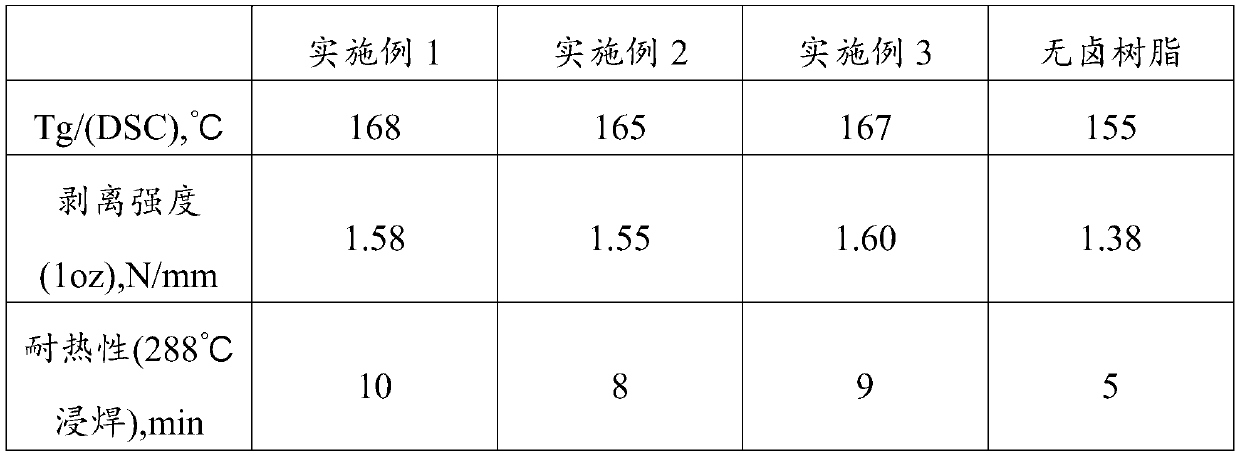

Examples

Embodiment 1

[0011] A halogen-free resin composition for copper clad laminates, comprising the following components in parts by weight: 650 parts of DOPO with an epoxy equivalent of 180g / eq, 60 parts of o-cresol novolac epoxy resin with an epoxy equivalent of 230g / eq , 25 parts of curing agent solution, 1 part of accelerator solution, 300 parts of silicon micropowder, 3 parts of KH5503 and 750 parts of acetone.

[0012] Wherein, the curing agent solution is prepared by mixing and dissolving dicyandiamide and DMF at a weight ratio of 1:10; the accelerator solution is prepared by mixing and dissolving 2-methylimidazolium acetone at a weight ratio of 1:10.

Embodiment 2

[0014] A halogen-free resin composition for copper clad laminates, comprising the following components in parts by weight: 720 parts of ODOPB with an epoxy equivalent of 200g / eq, 55 parts of BPA novolac epoxy resin with an epoxy equivalent of 230g / eq, 22 parts of curing agent solution, 1.1 parts of accelerator solution, 320 parts of talcum powder, 3.5 parts of KH560 and 720 parts of DMF.

[0015] Wherein, the curing agent solution is prepared by mixing and dissolving dicyandiamide and methanol at a weight ratio of 1:10; the accelerator solution is 2-ethyl, 4-methylimidazole and butanone at a weight ratio of 1:10 Prepared by mixing and dissolving.

Embodiment 3

[0017] A halogen-free resin composition for copper clad laminates, comprising the following components in parts by weight: 800 parts of DOPO with an epoxy equivalent of 220g / eq, 50 parts of DCPD phenol novolac epoxy resin with an epoxy equivalent of 290g / eq , 20 parts of curing agent solution, 1.5 parts of accelerator solution, 350 parts of aluminum hydroxide, 4 parts of KH570 and 700 parts of butanone.

[0018] Wherein, the curing agent solution is prepared by mixing and dissolving dicyandiamide and toluene at a weight ratio of 1:10; the accelerator solution is prepared by mixing and dissolving 2-phenylimidazole and acetone at a weight ratio of 1:10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com