Flower-shaped nitrogen-doped carbon-spinel type microspherical catalyst with high specific surface area as well as preparation method and application thereof

A high specific surface area, nitrogen-doped carbon technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of uneven dispersion of metal ion components, small specific surface area of tricobalt tetroxide, The performance can not be achieved better and other problems, to achieve the effect of rich surface active sites, simple introduction method, improved catalytic performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

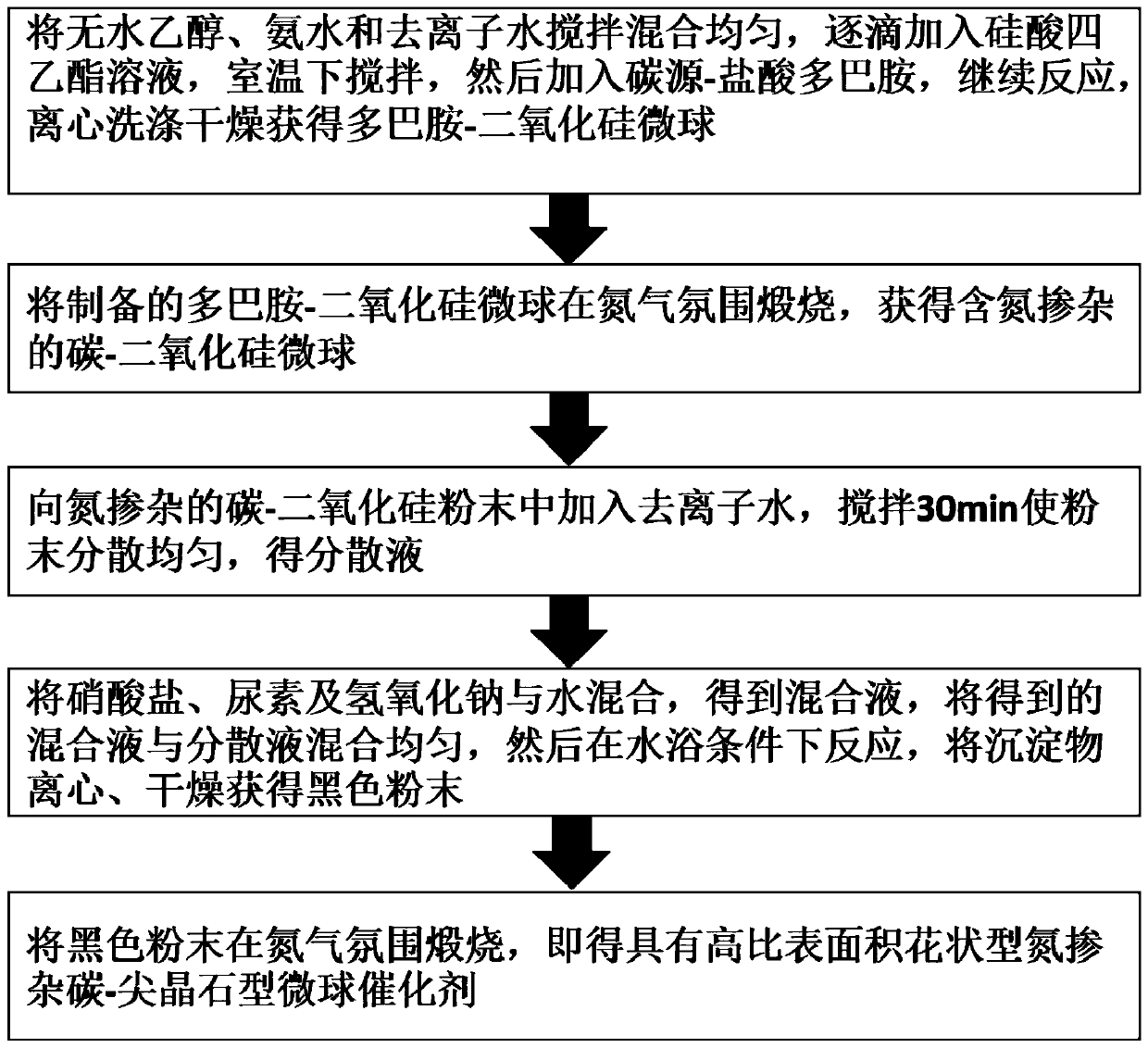

[0055] A preparation method with high specific surface area flower-shaped nitrogen-doped carbon-spinel microsphere catalyst, comprising the steps of:

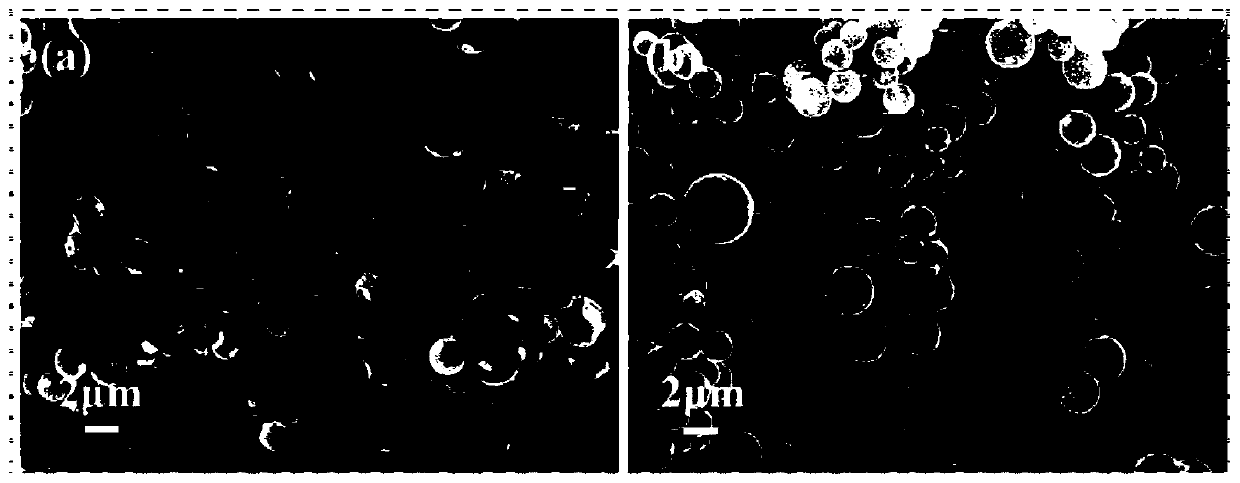

[0056] (1) Preparation of dopamine-silica sphere particles with controllable particle size; mix 48mL absolute ethanol and 2.0mL ammonia water (25wt% by mass), then add 160mL deionized water, stir for 10min, and stir evenly; Then add 2.0mL tetraethyl silicate, continue to stir for 30min, stir evenly; finally add 1.0g dopamine hydrochloride, carry out stirring reaction at room temperature, the time of stirring reaction is 12h, the stirring rate of stirring reaction is 4000rpm; , and then the precipitate was washed and centrifuged three times with deionized water and absolute ethanol respectively, and the precipitate was dried in an oven at 80°C for 3 hours, and ground to obtain dopamine-silica sphere particles (1-4 μm);

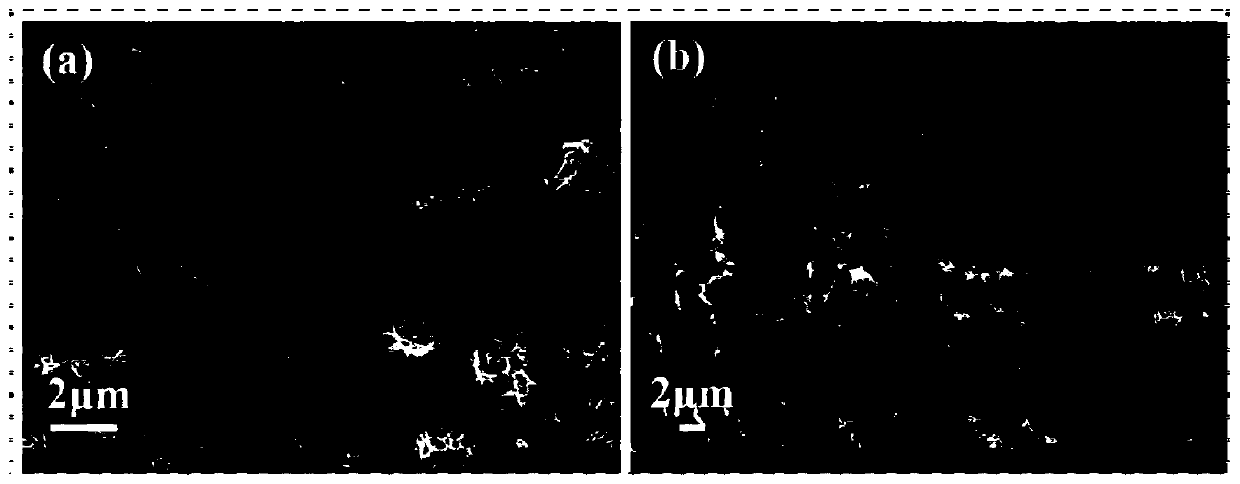

[0057] (2) Preparation of nitrogen-doped carbon-silicon dioxide particles: calcining the dopamine-silicon dio...

Embodiment 2

[0063] A preparation method with high specific surface area flower-shaped nitrogen-doped carbon-spinel microsphere catalyst, comprising the steps of:

[0064] (1) Preparation of dopamine-silica sphere particles with controllable particle size; take 48mL of absolute ethanol and 2.0mL of ammonia water (20% by mass percentage) and mix, then add 160mL of deionized water, stir for 10min, and stir evenly; Then add 2.0mL tetraethyl silicate, continue to stir for 30min, stir evenly; finally add 2.0g dopamine hydrochloride, carry out stirring reaction at room temperature, the time of stirring reaction is 2h, the stirring rate of stirring reaction is 4000rpm; , and then the precipitate was washed and centrifuged three times with deionized water and absolute ethanol respectively, and the precipitate was dried in an oven at 80°C for 3 hours to obtain dopamine-silica sphere particles (particle size 1-4 μm);

[0065] (2) Preparation of nitrogen-doped silica microspheres: calcining the dopam...

Embodiment 3

[0069] A preparation method with high specific surface area flower-shaped nitrogen-doped carbon-spinel microsphere catalyst, comprising the steps of:

[0070] (1) Preparation of dopamine-silica sphere particles with controllable particle size; take 48mL of absolute ethanol and 2.0mL of ammonia water (5% concentration by mass) and mix evenly, then add 160mL of deionized water, stir for 10min, and stir evenly Then add 2.0mL tetraethyl silicate, continue to stir for 30min, stir evenly; finally add 1.0g dopamine hydrochloride, carry out stirring reaction at room temperature, the time of stirring reaction is 2h, the stirring speed of stirring reaction is 6000rpm; Precipitate, then wash the precipitate with deionized water and absolute ethanol, centrifuge three times, dry the precipitate in an oven at 80°C for 3 hours, and grind to obtain dopamine-silica sphere particles (particle size: 1-4 μm);

[0071] (2) Preparation of nitrogen-doped silica microspheres: calcining the dopamine-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com