Exhaust gas automatic processing equipment suitable for spray booths

An automatic treatment and spraying room technology, applied in the direction of gas treatment, combined device, membrane technology, etc., can solve the problems of high water shower tower height, easy blockage of activated carbon, difficult to control, etc., to reduce waste water impurities, reduce purification operations, improve Cleansing effect and speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

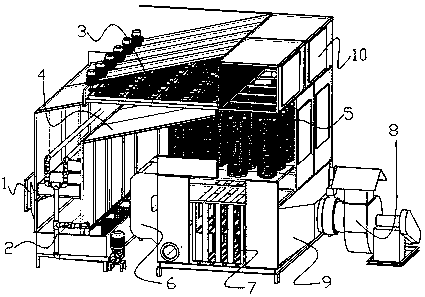

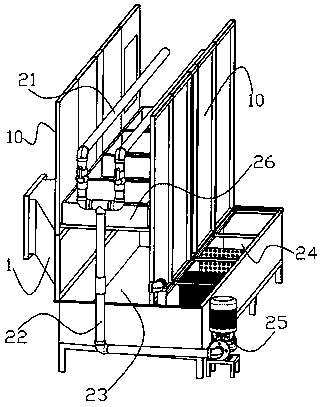

[0037] Embodiment 1, an automatic waste gas treatment equipment suitable for a spraying room. The air inlet end of the waste gas treatment equipment is connected to and communicated with the air outlet end of the spraying room, and the exhaust fan installed at the air outlet end of the spraying room blows the waste gas into the waste treatment equipment , the exhaust gas treatment equipment includes an air inlet port 1 and a detachable shielding box body 10; a washing tower 2, a dynamic shielding device 3, a dust removal filter 5 and an activated carbon adsorption chamber 7 are installed inside the box body 10 and communicated end to end in sequence, The air outlet of the spraying chamber is connected with the air inlet pipe of the washing tower 2 through the air inlet port 1 installed on one side of the box body 10, and the air outlet end of the activated carbon adsorption chamber 7 is connected through the air outlet port installed on the other side of the box body 10. 9 comm...

Embodiment 2

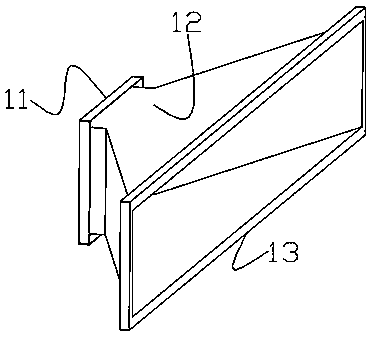

[0039] Example 2, such as figure 2 As shown, on the basis of Embodiment 1, the air intake port 1 includes an integrally arranged air intake fixing portion 11, an air intake passage 12, and an air outlet fixing portion 13 arranged in sequence from left to right, and the longitudinal direction of the air intake passage 12 The area of the cross-section gradually increases from the air inlet fixed part 11 to the air outlet fixed part 13; the air outlet port 9 and the air inlet port 1 are left and right symmetrical structures; further, the air inlet port 1 is connected to the washing tower 2 in the spraying chamber and the waste gas treatment equipment In the middle pipe, the diameter of the left port of the inlet port 1 near the spraying chamber is smaller than the diameter of the port near the scrubber 2, thereby effectively reducing the flow rate of the exhaust gas in the exhaust gas treatment equipment, and correspondingly prolonging the distance between the water sprayed fro...

Embodiment 3

[0040] Embodiment 3, on the basis of Embodiment 2, a socket board perpendicular to the exhaust gas flow direction is inserted on the air intake channel 12 of the air intake port 1, and the exhaust gas is changed by inserting the socket board into the air intake channel 12. The flow caliber in the inlet port 1, so as to realize manual flexible and step-by-step control / adjustment of the flow rate of the exhaust gas entering the exhaust gas treatment equipment; The noise generated by blocking; the specific installation of the plug board: the plug board includes a plug board, a support plate, a telescopic rod and a fixing nut, and a strip-shaped jack is opened on the upper part of the air inlet passage 12 of the air inlet port 1, and the plug board The upper end is fixedly connected with the lower middle position of the support plate, and the upper ends of the two telescopic rods are fixedly connected with the lower left and right sides of the support plate, and the lower ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com