Composite material based on silk fibroin fiber and heart valve prosthesis

An artificial heart valve and silk fibroin technology, applied in heart valves, medical science, prostheses, etc., can solve problems such as fibrous hyperplasia and calcification, fatigue tearing of polymer materials, etc., and achieve good long-term fatigue resistance and good fluidity Effects on dynamic properties, enhanced radial compliance and hoop strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, an anisotropic silk fibroin fiber composite material coated with polyethylene glycol hydrogel was used to prepare an artificial heart valve prosthesis with a stent diameter of 25 mm.

[0037] 1. Preparation of silk fibroin solution: Take natural silk and go through the steps of degumming, drying, dissolving, dialysis and concentration to make silk fibroin solution.

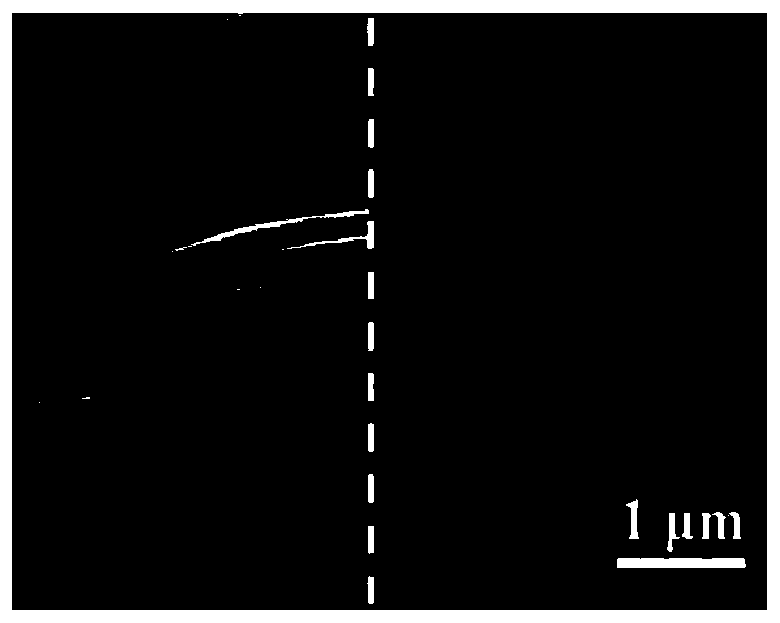

[0038] 2. Preparation of fiber material by electrospinning: the concentrated silk fibroin solution is mixed with polyethylene oxide (molecular weight ~ 300000) solution to prepare a spinnable silk fibroin solution. Carry out spinning under the conditions of low silk fibroin solution concentration (the content of concentrated silk fibroin solution in the spinnable silk fibroin solution is 10wt%), low spinning voltage (18kV), first use the drum receiver (number of revolutions) 2800rpm) to collect the anisotropic film and place it on the baffle to collect the isotropic film, and finally obtain...

Embodiment 2

[0046] In this example, an anisotropic silk fibroin fiber composite material coated with polyethylene glycol hydrogel was used to prepare an artificial heart valve prosthesis with a stent diameter of 23 mm.

[0047] 1. Configure silk fibroin spinning solution: same as Example 1.

[0048] 2. Preparation of fiber material by electrospinning: same as in Example 1.

[0049] 3. Coating PEGDA hydrogel: Same as Example 1.

[0050] 4. Cut the silk fibroin fiber composite material according to the required size of the 23mm stent, and place the silk fibroin fiber membrane according to Figure 4 Fold and suture in the manner shown, and suture it inside the stent (diameter 23mm) with medical sutures to make a heart valve prosthesis. When suturing, ensure that the silk fibroin fibers are arranged along the circumference of the valve leaflets, and ensure that the natural state is maintained after suturing. The fit of the three leaflets is good.

[0051] The hydrodynamic evaluation result...

Embodiment 3

[0053] In this example, an isotropic silk fibroin fiber composite material coated with polyethylene glycol hydrogel was used to prepare an artificial heart valve prosthesis with a stent diameter of 25 mm.

[0054] 1. Configure silk fibroin spinning solution: same as Example 1.

[0055] 2. Preparation of fiber material by electrospinning: under the conditions of low silk fibroin solution concentration (10wt.%) and low spinning voltage (18kV), the isotropic film was collected with a baffle. The prepared fiber membrane was carefully torn off from the aluminum foil, immersed in methanol solution to obtain a partially crystallized silk fibroin membrane.

[0056] 3. Coating PEGDA hydrogel: Same as Example 1.

[0057] 4. Cut the silk fibroin fiber membrane according to the required size of the 25mm stent, and place the silk fibroin fiber membrane according to Figure 4 Fold and suture in the manner shown, and sew it inside the stent (25mm in diameter) with medical sutures to make a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com