Novel multilayer structure with low electric leakage

A multi-layer structure, low technology, applied in the direction of electrical components, static memory, instruments, etc., can solve the problems of reducing the effective electric field strength, large thickness of the transition layer, etc., and achieve the effect of small leakage current and small leakage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

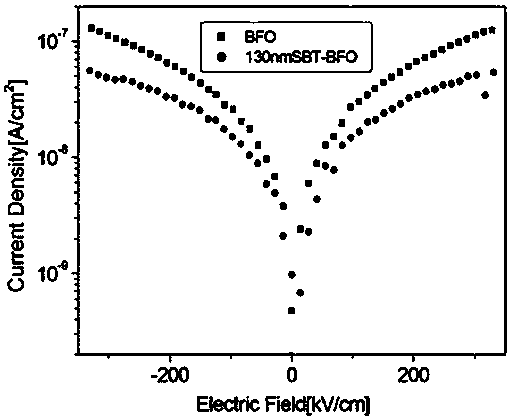

Embodiment example 1

[0033] (1) In the novel multilayer structure with lower leakage current for ferroelectric memory devices described in the present invention, Sr2 Bi 4 Ti 5 o 18 The preparation process of the transition layer and thin film layer precursor solution uses bismuth nitrate, strontium acetate, ethylene glycol, acetylacetone, and tetrabutyl titanate as raw materials, and is synthesized by a sol-gel method. The specific steps are as follows: Butyl ester and acetylacetone were prepared in a volume ratio of 1:1 to prepare solution A: tetrabutyl titanate acetylacetone was slowly dropped into the acetylacetone solution, and the mixed solution was stirred for 24 hours to obtain a clear yellow-brown transparent Solution A: Weigh 1.2g strontium acetate, 5.9g bismuth nitrate, and 18.8ml ethylene glycol, mix the three fully, place them on a multi-head magnetic stirrer and stir for 24 hours to obtain a transparent B solution; slowly add B solution into the A solution, and the mixed solution wa...

Embodiment example 2

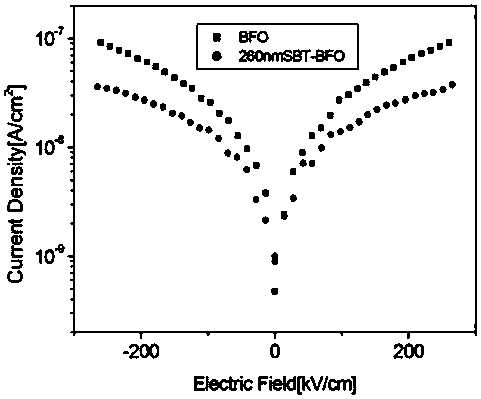

[0037] (1) In the novel multilayer structure with lower leakage current for ferroelectric memory devices described in the present invention, Sr 2 Bi 4 Ti 5 o 18 The preparation process of the transition layer and thin film layer precursor solution uses bismuth nitrate, strontium acetate, ethylene glycol, acetylacetone, and tetrabutyl titanate as raw materials, and is synthesized by a sol-gel method. The specific steps are as follows: Butyl ester and acetylacetone were prepared in a volume ratio of 1:1 to prepare solution A: tetrabutyl titanate acetylacetone was slowly dropped into the acetylacetone solution, and the mixed solution was stirred for 24 hours to obtain a clear yellow-brown transparent Solution A: Weigh 1.2g strontium acetate, 5.9g bismuth nitrate, and 18.8ml ethylene glycol, mix the three fully, place them on a multi-head magnetic stirrer and stir for 24 hours to obtain a transparent B solution; slowly add B solution into the A solution, and the mixed solution ...

Embodiment example 3

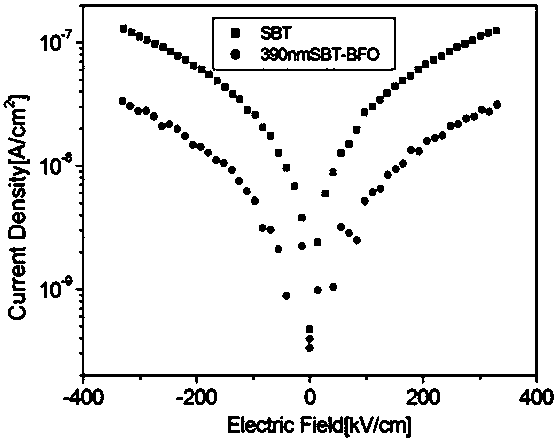

[0041] (1) In the novel multilayer structure with lower leakage current for ferroelectric memory devices described in the present invention, Sr 2 Bi 4 Ti 5 o 18 The preparation process of the transition layer and thin film layer precursor solution uses bismuth nitrate, strontium acetate, ethylene glycol, acetylacetone, and tetrabutyl titanate as raw materials, and is synthesized by a sol-gel method. The specific steps are as follows: Butyl ester and acetylacetone were prepared in a volume ratio of 1:1 to prepare solution A: tetrabutyl titanate acetylacetone was slowly dropped into the acetylacetone solution, and the mixed solution was stirred for 24 hours to obtain a clear yellow-brown transparent Solution A: Weigh 1.2g strontium acetate, 5.9g bismuth nitrate, and 18.8ml ethylene glycol, mix the three fully, place them on a multi-head magnetic stirrer and stir for 24 hours to obtain a transparent B solution; slowly add B solution into the A solution, and the mixed solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com