Manufacturing method of schottky diode compatible with cmos process

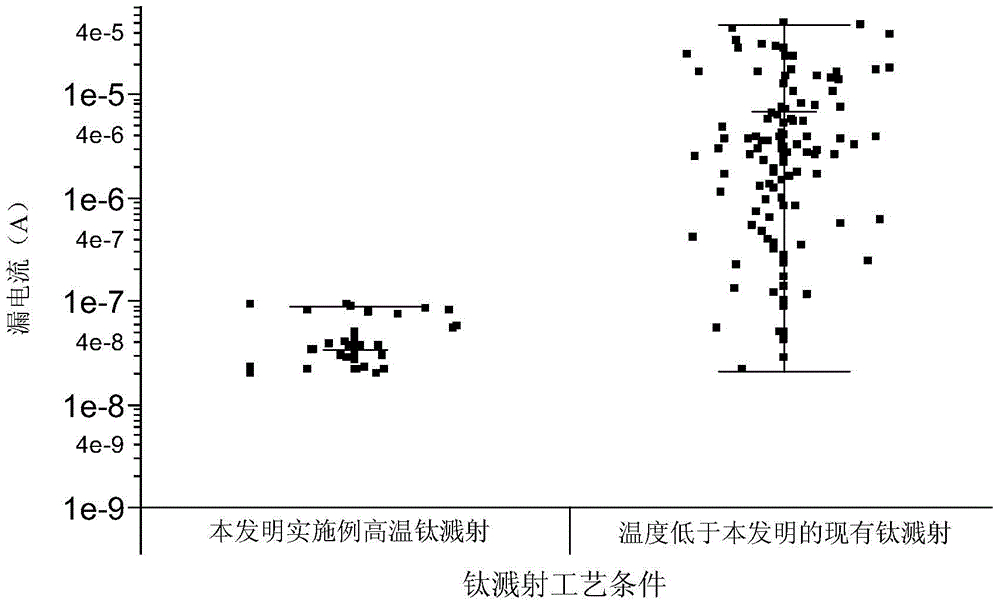

A technology of Schottky diodes and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as large leakage current and poor performance of Schottky diodes, and achieve reduced leakage, low leakage characteristics, Effect of reducing lattice damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

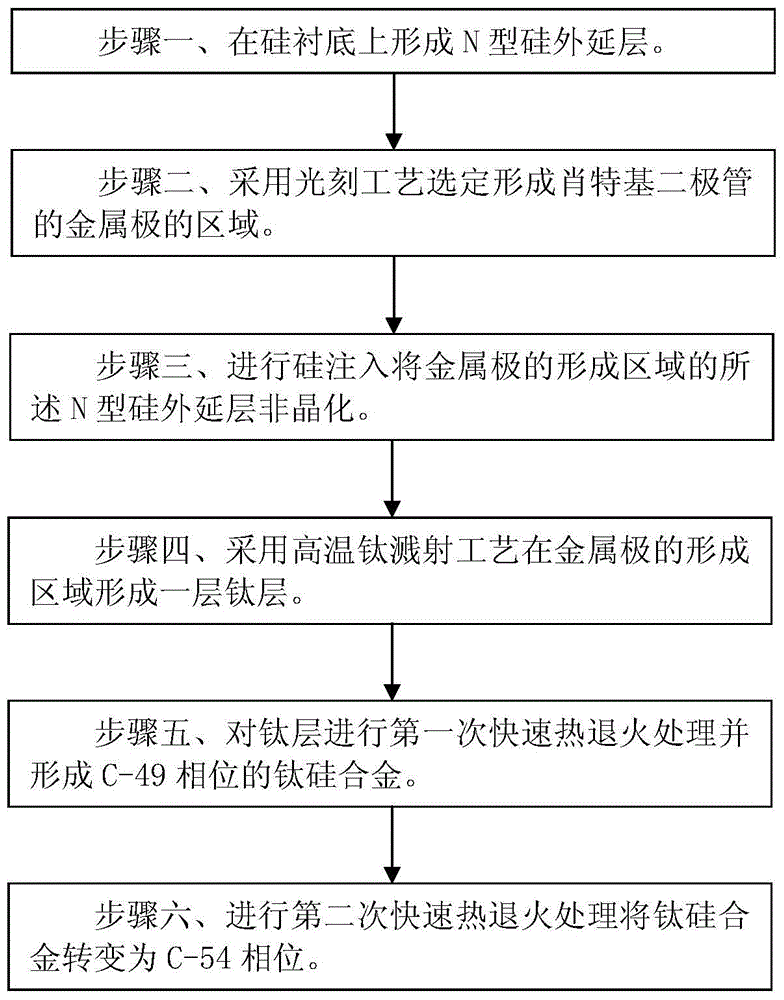

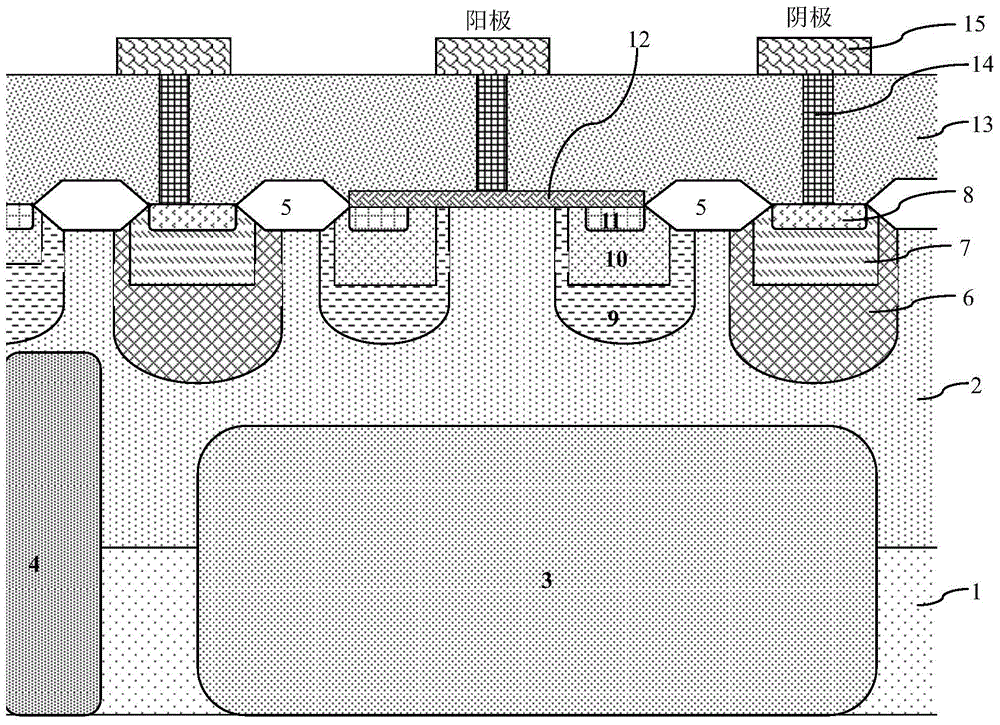

[0027] like figure 1 Shown is the flow chart of the method of the embodiment of the present invention; figure 2 Shown is the structural diagram of the Schottky diode formed by the method of the embodiment of the present invention; the manufacturing method of the Schottky diode compatible with the CMOS process of the embodiment of the present invention includes the following steps:

[0028] Step 1: Forming an N-type silicon epitaxial layer 2 on the silicon substrate 1, the doping concentration of the N-type silicon epitaxial layer 2 meeting the conditions for being a semiconductor pole of a Schottky diode.

[0029] Since the CMOS device and the Schottky diode are manufactured together in the method of the embodiment of the present invention, a step of forming a P-type buried layer 3 and an N-type buried layer 4 on the silicon substrate 1 is also included. The P-type buried layer 3 and the N-type buried layer 4 are located at the bottom of the N-type silicon epitaxial layer 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com